How to make backgammon with your own hands. Backgammon: the manufacturing process Drawings on wooden backgammon outside and inside

Backgammon is an ancient Eastern game. The exact place of their origin is unknown, but they are already about 5,000 years old, which is confirmed by historical manuscripts. The oldest board for the game was discovered in Asia Minor, in the town of Shahri-Sukhte. Scientists have determined that the thing was created approximately 3000 BC. e. The same board was found in

One of the legends says that one day they decided to test the resourcefulness of the Persians and presented them with chess. They believed that they would not understand the rules of this unusual game. However, the sage from Persia was able to reveal the secret and in response sent them his game, which the Indians could not solve for 12 years. Bozorgmerkh sent them nothing more than a game of backgammon (translated from Persian “backgammon takhte” means “fight on a wooden board”).

IN Western Europe The game spread thanks to the Crusaders in the 12th century. It gained popularity in the Middle Ages in European countries, where it got its name - backgammon. It simulates the impact of bones. The name "backgammon" was used among kings and nobles.

The game has gained considerable popularity in our time. Many craftsmen never cease to amaze with their new, original designs of inlay. This article will describe how to make backgammon with your own hands.

What does the game develop?

Just like chess, backgammon is designed to train thinking. Only in the first case does logical thinking develop, and in the second - resourcefulness and ingenuity. Scientists claim that after playing backgammon every day, the level of intelligence increases by 10%. Researchers in the UK came to this conclusion.

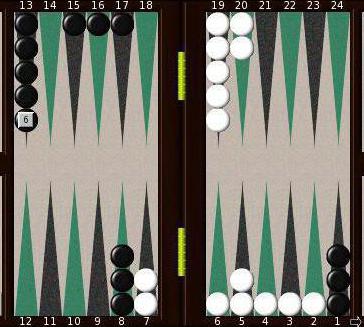

What does the board look like?

The board has a rectangular shape. It has 24 points (12 on each side). The board consists of two sides. Each point, as a rule, represents a narrow elongated triangle, the base of which is located along the edge, and the height reaches half the board. Six points on one side are called the player's house. Its location depends on the rules of the game. The board is divided down the middle by a vertical stripe called a "bar". Usually knocked down checkers are placed there. Each player has 15 of them. The move is determined by the pair - the charge. There are also two pairs for each player, as well as cups for mixing the dice.

Carpentry work when making boards

Many people are interested in how to make backgammon with their own hands. Even a beginner in wood carving can do this process. The first step is to draw up detailed drawing. In this case, backgammon will be obtained without errors in size.

You will need:

- plywood;

- slats;

- loops.

What should plywood be like? Polished thoroughly, it has no roughness or burrs, which is very important for the manufacturing process.

Board size

Before you make backgammon, decide what size board you want to get. They are different:

What is the main thing when carving on a backgammon board?

In most cases, carved backgammon, the dimensions of which are indicated above, are made in classic style with its inherent flat reliefs. Even beginners will be able to do this kind of work. Half the success lies in the right design. Ornaments with plants or arabesques became widespread.

For example, consider panels made of alder. On one side they are veneered with ash. If you want to do this part of the work yourself, it should be noted that the veneer is applied only on one side. After drying, the panel will bend towards the veneer. To avoid getting a similar result, you should glue the opposite side plain paper, maybe even a newspaper. When the glue dries, there will be no deformation in this case. When working with panels, it is recommended to place them on polyethylene from packaging with soft inflatable pimples. This will protect parts from damage during operation.

The film is placed with the smooth side facing the workpiece, otherwise during operation the chips will get stuck in the pimples and can damage the surface. When applying tone to a material, you may get an undesirable effect.

How to transfer a drawing?

The drawing is transferred to the workpiece using carbon paper. Stock up on a ready-made image, the scale of which is designed to be applied over the entire plane. This will help avoid breaking symmetry, which is a problem when making boards. important point. After transferring the drawing using carbon paper, it should be corrected by hand.

Selection of background for thread

At such a stage as selecting the background for the thread, there are two methods:

Carving tools

To make backgammon with your own hands, you will need the following tools:

- A blunt knife with an acute angle to the tip.

- Flat shape chisels in sizes 1, 2, 3, 5, 10 mm.

- Chisels with a semicircular shape measuring 6.9 mm.

Arabesque processing

After sampling the background in all hard-to-reach places, you should start working on the ornament. Start from the bottom and top edges of the panel. The intersections of the parts are cut with a knife. The depth is taken to be 2 mm. By trimming with a flat chisel, the lower and upper points of the design are revealed. Thus, the ornament will be intertwined.

Then future profiles of the drawing are drawn. Using a knife or a flat chisel, a convex part of the profile is formed. Then, using semicircular chisels, the concave parts of the profiles are processed. The operation should be repeated with the central part of the ornament. The drawing needs to be worked on a second time, correcting all the shortcomings.

Matting the background

Matting the background involves piercing it around all the carved elements. This can achieve the graphic quality of arabesques. For this purpose, you can use a simple sharpened screw. Various punches are also used. Then tattooing of all remaining parts continues. The carving process ends at this stage, and you can begin the finishing part.

Adding tone

Do-it-yourself backgammon involves tinting. For this process, you can use water stains. Usually one color is used, which is diluted to three shades: light, medium and dark. IN in this case Two types of wood were used: ash and alder. To emphasize the beauty of each of them, two stain colors were used: dark oak and teak. Teak is suitable for ash, and dark oak is suitable for alder.

First of all, the carved panel must be tinted. The lightest paint covers all the carvings. Then, without allowing the stain to dry, a medium shade is applied to the milled edges of the panel.

The next stage involves coloring the background. It is covered with the darkest tone. They do this with caution. The paint is applied with extreme care so as not to get on the light part. Painting should begin from the center of the selected background area, moving to the rising carved parts. In this case, a minimal amount of dye is taken with the brush.

The wooden surface should be allowed to dry, and then the other side should be covered with teak stain. The carpentry components of the boards are coated with the same tone.

After the stain has dried, the raised lint is removed using sandpaper. The main thing is not to damage the paint on the sharp edges that remain on the threads after working with chisels.

The entire board is coated with colorless varnish. For this purpose, a two-component matte varnish is used.

The second option for making backgammon

The manufacture of such a product as carved backgammon was described above. Another method involves burning patterns.

To make backgammon with your own hands using the second method, you will need:

Progress

The process of making a backgammon board in this case involves the following steps:

- The work begins with the design of the external and inside. The prepared drawing is burned on both sides according to the selected cliche.

- glued into a tenon and glued along the perimeter of the board.

- Holes for chips are cut out in wide slats and also glued.

- Next, the hinges and lock are installed.

- Finally, the board is coated with three layers of colorless varnish.

What chips are used?

The chips are machined from You can use ready-made plastic ones for playing checkers.

Conclusion

The most beautiful backgammon boards are not like chess boards. Their back side always decorated with magnificent patterns or designs. Handmade backgammon looks impressive. The price for such a product is quite high.

Dear colleagues. Today I would like to talk about backgammon and carving the board for the game.

Backgammon is an ancient oriental game. The origin of this game is unknown, but it is known that people have been playing this game for more than 5000 years, for which there is historical evidence. The oldest backgammon board was found in Asia Minor (in Shahri Sukhta) and dates back to about 3000 BC. An analogue of this game was discovered in the tomb of Pharaoh Tutankhamun. One of the legends testifies that once the Indians, wanting to test the intelligence of the Persians, sent them a set of chess, believing that they would not figure out how to play this wise game. However, the Persian sage Bozorgmehr not only easily coped with this task, but also offered his own, which the Hindus could not solve for 12 years. Büzürkmehr came up with it and sent it to his opponents new game- backgammon (backgammon ottoman - battle on a wooden board). In Western Europe, the spread of the game is associated with the return of the Crusaders from the Crusades of the 12th century. The game became very popular in medieval Europe and was called Backgammon. This name apparently came from the sound of bones hitting wooden board. At that time, the word “backgammon” was used to describe the game of kings. Only representatives of the highest aristocracy had the privileges of playing backgammon.

According to the Eastern tradition, the backgammon board was always richly decorated: with carvings, inlays, and paintings. Backgammon is also very popular in our time. This is confirmed by the number of views of the game boards on our website.

Meanwhile, for the most part it is a classic flat-relief carving, which is quite within the capabilities of novice carvers. For them, I think, the master class will be of the greatest interest. Half the success in decorating a game board with carvings lies in a well-chosen design. The most widespread plant ornaments are arabesques.

I will intentionally leave the carpentry part of board production behind the scenes; this is a job for carpenters. Let's move on to the carving.

Before us are alder panels veneered on one side with ash. If you are planning to veneer the panels yourself, it is worth remembering that if you apply the veneer on only one side, then when the glue dries, the panel will bend towards the veneer. To avoid this result, ordinary paper (newspaper) is glued on the other side, so no deformation occurs when the glue dries. I would like to draw your attention to the fact that the panels lie on packaging polyethylene “with pimples”: it perfectly protects the product from damage during operation. It should be placed with the smooth side facing the workpiece. Otherwise, the chips will be trapped between the bubbles and may damage the surface. As a result, an “unpleasant surprise” may emerge when tinting. There is only one drawback to using this polyethylene... you can get carried away with the popping of bubbles and spend the whole day in mediocre...

We transfer the drawing to the workpiece using carbon paper. In this case, only a quarter of the picture is drawn (the printer is broken). It is better to have a ready-made drawing for the entire plane at once. This will eliminate distortion of the symmetry of the drawing, which is very important in this case.

After transferring the drawing using carbon paper, we edit it by hand.

Let's start selecting the background for the thread. There are two ways: the first is the classic one - cutting with a knife along the contour of the design, followed by sampling the background with flat chisels (it is necessary to clarify that the knife in this case should enter the wood exactly at 90 degrees). If it is not possible to maintain the perpendicularity of the knife to the workpiece, then you can tilt it slightly at an arbitrary angle away from the leaves of the ornament, and later, when working on the carving, correcting the pattern that is distorted because of this. The second way is to select the background using hand router and a “finger” cutter, in this case that’s what I did. The advantages of this method are speed, exact 90 degrees along the edge of the ornament, background sampling around all elements is carried out clearly at the same level. Hands do not get tired in the labor-intensive process of background selection. Among the disadvantages: the need for a router, and the impossibility of using it at home due to noise and dust.

So, the “rough” background is selected to a depth of 5 mm; as you can see, there are places where the cutter did not reach; we remove them using a knife and flat chisels.

Here you should strictly follow the rules given in the first method of background sampling. No one has canceled working with their hands.

It's time to familiarize yourself with the necessary tool kits: a jamb knife, preferably with the sharpest angle to its tip from your entire arsenal. Flat chisels 1, 2, 3, 5, 10 mm. In my case, they were made from sharpened Soviet needle files. Semicircular chisels 6.9 mm.

After the background has been selected in all hard-to-reach places, we begin working on the ornament. Let's start with the bottom and top edges of the panel. Using a knife, we cut through the intersections of the ornament details with each other to a depth of 2-3 mm, identifying the upper and lower points of the ornament, and trim with a flat chisel. Thus intertwining the ornament.

Trimming should be done as shown in the figure. Red line is wrong, green line is right.

The result of our actions: the ornament looks like this.

We draw our vision of future drawing profiles.

Using a knife or flat chisels (whichever is more convenient for you), we first form the convex part of the profile.

Then, using semicircular chisels, create concave profiles.

As a result, the ornament looks like this.

We repeat the operations with the central element of the ornament.

We work through the entire drawing again, correcting all the noticed flaws in more detail.

Now you can start muating the background. We start by “piercing the background” around all the carved elements, achieving a graphic image. For this I use a simple sharpened screw. Not aesthetically pleasing, but cheap and practical. You can also use various punches for this.

Then we continue to “prick” the entire remaining background.

We admire the result. The carving is complete at this stage and you can begin finishing works. Were chosen for tinting water stains. I usually use one color diluted into three tones: light, medium and dark. Two types of wood were used in this work, and to highlight the merits of each, two stain colors were used: Dark Oak and Teak. Teak - for ash. Dark oak (diluted by three tones) for alder.

First, the threaded panel is tinted. We cover the entire carving with the lightest dye. Then, until the stain is all dry, apply a medium tone to the milled edges of the panel. Next stage: move on to the background - the darkest tone. You should be careful and try to apply the dark tone as carefully as possible. To prevent the dye from getting onto the light areas of the carving, we begin to paint from the center of the selected area of the background, approaching the towering elements of the carving with a minimum amount of dye on the brush. Let the work dry, and open the ash veneer on the other side with Teak stain. Using the same stain, we open up the carpentry elements of the backgammon board.

After the stain has dried, we remove the raised lint with sandpaper (you can use old worn sandpaper). Or, as I used in this case, Indasa RHYNO SPONGE - a special flexible abrasive on foamed polyurethane coated with aluminum oxide, tear-resistant. Ideal for finishing, primers and varnishes and processing in hard-to-reach places (I'll post photos later). The main thing is not to damage the stain on the sharp edges remaining on the thread after working with chisels.

We evaluate the result and cover the work with varnish. For such work I use a two-component matte varnish. Let's look at the finished backgammon.

You can make a backgammon board yourself, preferably from wood, although plywood will also work, the main thing is that the surface of the playing field is smooth and polished!

Option 1

Let's make backgammon from oak boards, about 5 cm thick. First, let's make blanks for the backgammon frame - a plane for playing them. The boards need to be sawn into thinner planks that are glued together. It turns out flat field for Game. Please note that in this way adjacent planks compensate for each other's warping. You can take a single sheet of plywood and divide it into 2 equal parts to create a base for a folding board. Folding backgammon fields are boxes that allow you to fold all the chips and dice after the game and store them on for a long time without losing.

The markings on the inner playing side of the board follow the 6+6 principle. Inside the sides it is necessary to mark holes for chips. Sometimes these holes are cut out from separate boards and nailed or glued on top, thus creating sides that mark the boundaries for placing chips. Next, a design is cut out on the outside; it is usually done using a special machine. Then the resulting playing field is tinted and the two folding parts are assembled by hand. The parts must fold and unfold freely. Select two mechanisms that ensure free movement of the halves of the backgammon field. Polishing is also important to avoid splinters and uneven surfaces. It is necessary to carefully check whether the boards fit together so that Over time, no cracks have formed.

The second part of the work is making the chips themselves. Make them too You can make them from wood or choose flat chips of the same size from another material - for example, from an old children's plastic toy.

Sometimes the backgammon board is combined with a chessboard on the other side. After you have made backgammon, you should not rush to play. The wooden product needs to rest for some time. 10 days will be enough.

Option 2

- To make backgammon with your own hands, you need to take two suitable sheets of well-polished plywood measuring 480 mm on one side, 210 mm on the other, 4 mm thick.

- For the pattern on the inner surface you need to prepare 3 colors: 2 shades Brown, one light or bronze paint in a can.

- Using a stencil, transfer the design to the surface, then glue a veneer of a matching color onto it. This operation requires accuracy and leisure.

- You can cover the surface of the board with a stencil applied to it with bronze paint.

- If the paint is not spray paint, use plain bronze paint and a sponge.

- Make blanks for the frame from thin slats. First glue the slats together, then glue them to the board.

- Cover the finished drawing with several layers of varnish.

- On lathe it is necessary to grind chips with a diameter of 25 mm and a height of about 12 mm in the amount of 30 pieces. Leave 15 chips light, and cover the other 15 with stain. Apply varnish in several layers.

- You can make chips from checkers. To do this, buy 2 checkers sets and select required amount chips of two colors.

- If you are good at wood carving, carve an oriental pattern on the outside.

- Cut plywood trims for the outside. They should be about 20 mm smaller. Glue them.

- Mark the boundaries of the overlay with a curved plinth, you can buy it.

- Attach loops on one side and a hook on the other to both halves of the board.

- You can make not a folding backgammon board, but a stationary table. The surface of the old coffee table is marked, veneer is glued on or covered with paint through a stencil. They make the sides. Cover everything with several layers of varnish.

Option 3

Find planks four centimeters wide and form dimensions from them. Using chips, draw half holes on the side slats and cut them out with a hand jigsaw for plywood. Then put all this on two pieces of plywood and lightly nail it with nails. Spread the slats with PVA glue (only Korean and in no case Russian, it is called Kong and usually comes as an additive to wallpaper glue under numbers 204, 205, etc.). Then or in advance you can put a pre-prepared picture like beautiful wallpaper or simply burn or paint, although this is more difficult. Better wallpaper there is nothing. The thickness of the slats is from one to one and a half centimeters.

Option 4

True connoisseurs of this game always have a beautiful board, and some even purchase a special table for playing backgammon - an ordinary one coffee table, on the surface of which drawings-marks for the game are applied. The choice of such boards and tables is huge: there are wooden crafts self made, there are glass products. What makes them beautiful is usually the intricate patterns applied (by hand or at the factory). And everything would be fine, but such boards and tables are oh so expensive, so not everyone can afford to buy such a luxurious thing.

Previously, we used to play backgammon on a regular wooden folding board, bought in a store. And although this board was very beautiful (carved and painted by hand), it was very large and bulky. Constantly taking it out and putting it back in the closet was tedious and troublesome.

My husband has long dreamed of a backgammon table. But we couldn’t find a suitable one - those that we liked were very expensive, and those that suited us in price did not suit us in appearance.

Then my husband suggested making the table ourselves. In addition, our usual coffee table was already quite worn out and we wanted to throw it away, so taking a risk and trying to remake it was quite possible.

In the shop furniture fittings we bought decorative ones plastic corners. In the building materials department we purchased bronze spray paint in a can and wood varnish. For the drawing we chose the drawing of our playing board. Having cut out whatman paper to the size of the table, we redrew the drawing from the board onto it. I had to tinker a little: the dimensions of the table and the board did not match a little, and the drawing itself turned out to be intricate. When the drawing on whatman paper was ready and represented the future surface of the table, we carefully, with small scissors, cut out all the arrows and monograms of the drawing. The result is a stencil.

Having degreased the surface of the table, we attached the stencil to it with “double” tape. From a distance of about 30 cm we applied bronze paint to the table. We applied the paint on top so that it would not spread under the whatman paper stencil. Instead of spray paint, you can use regular paint, but you will have to apply it to the table not with a brush, but with a piece of sponge.

After waiting for the first layer to dry, we applied the second. After both layers had completely dried, we carefully peeled off the stencil and varnished the design. We glued decorative plastic corners to the corners of the table, which were also pre-coated with bronze paint. I glued golden sequins to the sides of the table, which highlighted it well. East style. To prevent the sequins from clinging and coming off, we also varnished the sides of the table. .jpg)

Now we no longer have to fiddle with the game board - in a matter of seconds we can place the pieces and play. And we didn’t have to throw out the table - you won’t find such a beautiful and practical table in any store!

If you are inspired by our idea, go for it! Instead of markings for backgammon, you can put a chess pattern on the table (for fans of checkers and chess), or you can simply decorate it with some intricate design. The main thing is to show your imagination!

Option 5

Many factory-made boards combine the ability to play chess, checkers and backgammon, that is, 8x8 squares are drawn on one side of the board, and 6+6 markings are applied on the inside. There are holes for chips along the sides. Thus, chess pieces and checkers (chips), along with dice, are conveniently placed inside the board, which is folded in half and closed with a latch.

Many “craftsmen” have modernized their chessboards for backgammon. Indeed, this is the easiest way to do it, and the chips can be carved from wood or borrowed plastic ones from an unnecessary children's game. Basically, if you buy two sets for playing checkers (there are twelve pieces each) different colors) you can select 30 chips for backgammon, fifteen of each color. Although all this will not be solid, such a set can be used to play backgammon at home. But it is unlikely that you will go somewhere to play for money with such backgammon.

Who doesn’t like to spend time in the evening playing an exciting board game in the company of loved ones? And the masters of their craft know how not only to play, but also to do it themselves Board games. In this master class you will learn how to make backgammon. In the process you will have to put in a little effort and time, but the result, made with your own hands, will be worth it.

We make backgammon step by step with our own hands in a master class

Necessary materials:- walnut, maple and mahogany veneer;

- MDF 6 mm thick;

- brass screws 4.5x25 mm;

- tools;

- sawing machine;

- magnets.

The board game will be made of plywood. It is also possible to make it from plexiglass or wood.

Instructions:1) We start by preparing the veneer. Using a ruler, measure strips of walnut and maple material measuring 38x191 mm. and cut it out.

2) Made of wood with a thickness of 13 mm. we cut out the top plates with dimensions of 38x254 mm. and lower ones 51x254 mm. in the upper plates we measure a distance of 25 cm from the ends and make mounting holes 4 cm in diameter.

3) Lay out 15 pieces of veneer strips in 4 piles. Then we align the edges and clamp them into the edges between the top and bottom plates.

4) Use brass screws to secure the top plates.

5) Using a sawing machine, we file the edge of each package at a disk with 60 teeth.

6) Make a note about the sawn edge at the end of the plate.

7) Rotate the package 180 degrees. Then we press it with its straight edge against the longitudinal stop and use the machine to file the second edge of the bag to a width of 33 mm.

8) We perform a similar sequence of actions with the remaining packages.

9) Take tape and stick strips on the sides of the veneer bags. We saw off the marked end, thereby shortening the package to a length of 203 mm. To do this, we use a miter gauge rotated at an angle of 5 degrees. We repeat the same action with other packages.

10) Set aside a distance of 32 mm. at the end and 165 mm. – on the side of the package and put marks.

11) Align the marks, trace the package to secure it on the base of the stop and the die.

12) We saw the veneer package according to the photo.

13) Now we begin to create an ornament from triangles. We take a strip of veneer that we will use to align the triangles during assembly.

14) We begin to assemble the field square. Using oil tape, glue the light and dark triangles to the “ruler,” alternating.

15) Glue the light and dark triangles together in pairs, first with tape, and then attach them to the edge of the ruler.

16) The square will be completed when there are 7 light and 6 dark triangles.

17) Remove pieces of tape.

18) We make three more squares in the same way.

19) Take two pieces of maple veneer, attach and align them to the edges of half the playing field.

20) Glue one quadrant evenly to the edge of the dividing strip.

21) Transfer the position marks of the vertices of the triangles to another dividing strip.

http://stroyboks.ru/wp-content/uploads/2015/08/2015-08-02_10-22-14.jpg

22) Attach the second quadrant with glue and align it in accordance with the marks.

23) Similarly, we assemble the other half of the playing field.

24) Cover the entire surface of the set with tape, and then remove its pieces from the bottom side.

25) Trim both parts of the playing field to a width of 191 mm, and then align the edges.

26) From maple veneer we cut out two strips equal to 48 mm wide. They will become the side fields of the playing field, which are used to store checkers. Align their edges and glue them to one edge of each set using tape.

27) We cut out four 19 mm wide slabs from MDF. and two pieces of veneer 255x432, as well as two bases from the picture below (under number A) 6 mm wide.

28) Apply PVA glue to the base and place a sheet of veneer on top, which is then covered with a sheet of waxed paper.

29) We compress the package between MDF parts with a thickness of 19 mm.

30) After the glue has dried, remove the clamps and apply the veneer to the second base of the field with further gluing.

31) We use a sawing machine to trim the playing field.

32) Place the router on the table and secure a 6 mm wide cutter in its collet.

33) Mill the folds on all sides that are not covered with veneer. In this case, you need to adjust the overhang so that the veneer thickness is slightly more than 3 mm.

34) Glue the playing field to the other side of the base using wax paper, pressed plates, a clamp and glue. After the glue has dried, you need to repeat the action with the second base.

35) Now we insert the bases with the playing fields into the box, and then glue them and divide them into two halves.

36) We make two blanks 67x460 (in the pictures above for Figure B) and 67x300 mm. - for S.

37) Turn the blanks towards you inside And saw blade we make 3x6 mm tongues. parallel to the edges, while making a 3 mm indent from the edge.

38) Using the same method, we will mill out the roundings of both edges with a radius of 1.5 mm.

39) The next step is to saw off the workpieces to the required length, while making bevels at their ends for connection.

40) When the parts have dried, assemble the box and insert any of the bases with the playing field, but only one.

41) We set the sawing machine to a width of 32 mm. and divide the box into two halves.

42) We cut out long partitions (in the picture under the designation D) and glue them to the right place.

43) We do the same with short partitions (E in the figure), focusing on the length of the partitions D, and then glue them.

A complete set of backgammon consists of a playing board, thirty chips and two dice. The shape of the playing board resembles a closed book measuring 660*310mm (opened 660*620mm) and 35-40mm thick. It opens up, like a chessboard.

If the inner plane of the board is mentally divided into four equal parts by mutually perpendicular lines, you will get four rectangles. On some modern boards they are designated by letters of the Latin alphabet: A, B, C, D. They are placed in the middle of the smaller sides of the board (Figure 1).

On each quarter of the board there are six semi-circular nest-fields, the radius of which is equal to the radius of ordinary checker pieces - 15mm. Chips move along these slots (along the perimeter of the board). The nests are numbered from one to six, starting from the outer (side) side of the board.

Above each field there is a sector with a height equal to five chip diameters (165-180mm). The sectors are drawn on the light plane of the board with black lines.

On standard boards, quarters of the board are not marked, fields are not numbered, the placement of chips when playing long and short games is not indicated, and the directions of movement of the chips are not given, and this is very important, especially for beginners.

DIY backgammon game

At the same time, 15 white and 15 black chips participate in the game. Regular checkers with a diameter of 30mm are suitable for a backgammon board of this size.

To determine the player who starts the game first (with white checkers) and the length of moves, two dice are used - black and white. The cubes are called "bones" or "zari". On the planes of the cube (side size 10-12mm) dots are applied - from one to six, like in dominoes. The edges and corners need to be slightly rounded so that the cubes roll freely when thrown.

In order to make your own backgammon board, you will need: two pieces of plywood 4mm thick, size 260*500mm;

eight wooden slats 10mm thick, 25mm wide (four - 260mm long and four - 500mm long);

two furniture loops measuring 30*30mm;

one or two furniture hooks for locking a closed board;

carnations 10 and 12 m long;

eight screws 8 - 10 mm long for hinges;

slats for figured strips (4 pieces).

Semicircular cutouts for nests on the slats can be cut out with a jigsaw, but it is better, if possible, to drill through holes and then saw it in half lengthwise. Then you will get two planks at once. The dimensions of the strip with sockets are shown in Figure 2.

Pieces of plywood, slats and planks need to be thoroughly cleaned with emery cloth. The slats are connected strictly at right angles, as shown in Figure 3. The shaped slats should fit tightly between the long slats. After the frames are knocked together, connect both rectangles with loops. They must be embedded so that they do not protrude above the surface of the slats and so that the heads of the screws are “recessed” into the holes of the hinges.

Then you need to put plywood on the outside of the frames and temporarily nail them with two nails. Then open the board and trace with a pencil along the inner and outer perimeter of the frames. Place the shaped strips inside the board and also trace along the contour of the nests.

Then detach the plywood from the frames, saw and plan them around the perimeter, apply all the markings with a pencil (Figure 1) and, if desired, design the outer planes. After this, cover all parts with one layer of colorless furniture varnish, rubbing it well into the surface of the wood. When the varnish dries, use black ink to outline the pencil marks. Contour lines should be 0.8mm thick. On the cross slats of the frames with enamel or oil paint apply letter designations: A, B, C, D. Then coat all the parts with varnish one or two more times, dry well and finally nail the lids to the frames. Then install the shaped strips and nail them with nails on the outside of the lids.

For playing backgammon, you can also adapt a regular chessboard. Then you need to design it from the inside and make figured strips in accordance with the dimensions of the board. Chips will be needed smaller diameter, according to the size of the resulting nests.

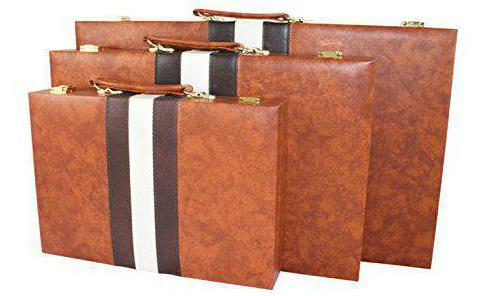

HomeNewsCase for chess and backgammon: we make it ourselves

Case for chess and backgammon: do it yourself

Case for chess and backgammon - well made, from good wood, beautifully decorated - can become as exclusive an item as a box. To do this, it is not at all necessary to buy expensive handmade kits. We will tell you how to make a case with your own hands, and what you will need for this.

Choosing a tree

First of all, you need to choose the wood from which the chess or backgammon box will be made. Typically one of four types of wood is used:

1) beech is a non-sharp material, and it is easy to tint it in any color, which is why it is preferred by many;

2) pine is a fairly easy-to-work material, especially if you are planning a light-colored box;

3) oak is valued for its hardness, but during processing an element may break off;

4) ash has beautiful drawing, and is also slightly inferior to oak in hardness.

Making a wooden blank

You can make the blank yourself, or order it from the workshop, specifying everything required sizes, and if there is a suitable old, shabby case, take it as a base. From such a product it is necessary to remove the old fittings, and then use sandpaper to remove the old varnish and paint.

If you have time, you can make the blank yourself. For this purpose, a plane is prepared on which they will play. It is recommended to cut the boards into thin planks and then glue them together. The result will be a flat playing field, but the slats will compensate for each other's warping. More simple option will take a sheet of plywood and, dividing it in half, create a base for a folding board. In any case, it is important that the boards fit together, otherwise cracks may form in the future.

Next you need to add sides to get boxes for storing chips. On the inside playing side of the board, markings are made according to the 6+6 principle (8x8 for chess), and holes for chips are marked inside the sides. They can be cut separately from planks and attached on top to form borders for placed chips.

Selecting accessories for chess and backgammon

Backgammon accessories include different elements:

- locks;

- overhead loops;

- fasteners in the form of nails, screws and self-tapping screws.

It is very important to choose loops that will look harmonious in the product, without going out of style and color. However, the color can be adjusted using appropriate metal paint.

The mortise ones look beautiful decorative loops and locks for caskets and caskets. Many professionals recommend purchasing lamber hinges, which are not noticeable at all when closed. They are cut not into the end of the box, but into the face, and here it is easiest to use a CNC machine. You can also attach leather loops measuring 1.5-2 mm with nails. You can choose leather to match the color of the tint or, conversely, a contrasting shade.

Locks can also be metal or leather. Convenient and practical option- closure with magnets or pin. There are also rim locks with an eye, which when high quality performances serve long and well. Usually they fit well into the oriental style of the case.

When choosing metal fittings, give preference to the one that weighs more, as this indicates good quality alloy It is desirable to have good protective covering, which is difficult to scratch.

Drawing

A beautiful backgammon box usually has a pattern on the outside that can be applied in different ways:

- burning

- painting

- thread

- drawing.

The design can be applied using a stencil. The printed pattern is placed exactly in the center of the material, covered with tracing paper on top (it can be lightly oiled) and secured with buttons on one side of the pattern. Then old, not too black copy paper is placed under the drawing, and everything is secured in the corners. The drawing is traced on tracing paper with a pencil and then transferred to wood.

Burning is done with a special electric burning device, but some people use a regular soldering iron. A special knife is used for carving, but you will need to clearly mark each element, down to the smallest detail, and work it out. This method of decoration takes more time.

Few beginners come up with their own patterns, since it is easiest to use ideas you like from the Internet, sometimes combining them. You can lay the stencils on the surface and cover the surface with paint from a spray can or from a can using a swab. Before painting, the wood must be coated with primer for acrylic paints. On top of the dried primer, you can apply acrylic paint to the sides with a wide flat brush, covering the bottom with masking tape. If you are drawing acrylic paint, then in case of an error it will be possible to apply a new layer and hide the defect.

Here's a classic way to transfer a pattern to wooden surface using tracing paper:

You can also use the method of transferring a printed image from paper to wood using glue to decorate the case:

If you are not confident in your drawing abilities and do not want to use a template, then good decision It may turn out to be craquelure varnish, which will create a beautiful decorative effect of “antique cracks”. After the varnish has dried, paint of a different color is applied, and cracks appear in it.

Finishing

After the image is ready, the surface is subjected to finishing. Thanks to it, the backgammon case will look respectable for many years.

DIY backgammon with bright patterns

This is done using varnish. A universal option You can call it a spray varnish. It dries quickly, lays evenly, and goes well with craquelure varnishes.

Suitable for decorative arts acrylic varnishes on water based, which are divided into glossy and matte. The first ones give an even beautiful coating with a glossy shine, and the latter are invisible. Usually they are odorless and dry quickly, but you need to take into account that with intensive use such compositions may not be the best. They are quickly applied with a soft flat synthetic brush No. 16. A thin layer of varnish should be spread well over the surface.

For maximum protection choose yacht varnishes- also matte and glossy. They turn slightly yellow, but for the vintage style this is even an advantage. It has a strong smell and you need to work with it with gloves, using a foam sponge for application. A good alternative would be POLY-R parquet varnish, which does not have yellowness. It is applied in the same way as yacht paint, but does not have a strong odor, dries much faster and gives a beautiful shade.