How to make a practical table from ordinary boards without being a woodworker. DIY garden table (44 photos): selection of materials and tools

This item furniture - one of the most versatile in use. The table can be a dining room, a utility table, or installed in a living room, on a veranda, on a property, in a workshop, and so on. In a word, it is impossible to do without it. But many people are not satisfied with purchased products in terms of a number of parameters - size, design features, form or for any other reason.

Considering that wood is relatively easy to cut and sand, making a table from it according to your own drawing, with your own hands, is not a problem for a good owner. And it will come out much cheaper. Plus - satisfaction from such work.

Room

Ideally, this is an extension, a barn, an empty garage, although a small area under a canopy will do. Working with wood on the site, in the open air, means being completely dependent on the vagaries of the weather. If there are “square meters” suitable for making furniture, then you should worry about quality ventilation in advance. Natural is sometimes not enough (besides, it depends on changes in wind direction and pressure), and a hood is installed.

Arguments that if you use protective equipment, you can work in closed space, do not stand up to any criticism. Wood dust will immediately settle on everything, including the sample with which some action is being performed. Neither an accurate cut along the line nor high-quality surface treatment of the wood (not to mention the impregnation and finishing coating with paint and varnish) will be possible.

One cannot ignore the fact that many preparations used for wood processing contain toxic components. For example, varnishes, paints, impregnations: if they are not natural, then harmful fumes are guaranteed.

Tools

Their selection depends on the extent to which it is planned to “ennoble” simple design made of wood, what shape to give it and a number of other nuances. If the master does not lay claim to the elegance of a wooden table and does not aim to achieve its originality, then an ordinary carpenter’s set will be enough.

For more “delicate” work in the process of making a table of unusual shapes and external design, special devices will be needed.

El/jig saw. It will not be possible to make an inclined vertical cut with a regular saw, maintaining the angle exactly. The canvas will begin to “play”, and therefore the quality of work will be extremely low. An electric jigsaw is universal in use and also provides high precision cutting of wood or cuts in it.

Many of the listed devices can be rented if making furniture is not a hobby, but a necessity.

Impregnating and other compositions

Rot protection:

- Working off machine oil– an effective, and also free, remedy. But not for dining tables.

- Flaxseed oil. A natural and effective product that penetrates deeply into the wood structure and protects it from mold and mildew. The downside is the high cost. But if the table is intended for eating, this is a great option. The drug has no color, therefore, after processing lumber, it does not leave any traces in the form of darkening, stains, or streaks, unlike processing.

- Water-polymer emulsion. It is characterized by long-lasting action and safety for health.

- Acrylic varnishes. They have practically supplanted their predecessors in the “NC” category, since they are harmless and in many respects better compositions, which are diluted with solvents.

- PVA, bone glue and a number of others. More detailed information about joinery compositions -.

To decorate a tree:

- Clear varnishes are used not only to protect the material from moisture. With their help, you can preserve the texture of the wood and shade it.

- Stains.

- Varnishes with a coloring effect (tinting).

- Paints (but only for wood!).

- Putties.

Using colorless varnish and pigments, you can make a coloring composition of any shade. It is enough just to correctly determine the proportion of components. This is easy to do by experimenting with mixing and applying a sample to a discarded board. This will allow you to choose an acceptable tone. It is more than advisable, since it is not always possible to purchase exactly what you need on the market.

Fasteners

It is better to ignore all advice on assembling a wooden table using nails (the reasoning is simple, quick and cheap). The reasons are as follows:

- The nail pricks easily dry wood(and this is exactly what is taken; more on that below).

- It is quite difficult to direct its leg correctly (strictly vertically). In some cases, it is even more difficult to redo your mistake.

- A tree, even the most protected from rot, succumbs to it over time. The maintainability of a table knocked down with nails is extremely low. Practice shows that it is rarely possible to remove such fasteners without damaging adjacent structural parts. As a result, instead of the planned replacement of one element, 2–3 will have to be changed.

- When assembling a wooden table, if glue alone is not enough, you should use only self-tapping screws.

- Sometimes its individual parts (at joints) require reinforcement. Strengthening the strength with hardware with a thicker and longer leg is impractical. The reason is the same - the likelihood of the tree splitting. For these purposes, metal strips, brackets, and corners are used.

Features of choosing wood

Some people focus on the cost of lumber, others care about the wood’s resistance to rot, and for others, its texture. What can you recommend to a novice furniture maker? Do not use the same type of wood for a table unless it is intended to be installed somewhere in a utility room or garage. This is exactly what many novice “craftsmen” do, selecting the same type of boards and bars from what is left from construction or renovation and gathering dust in the barn.

When making a wooden table for a living space, veranda, etc., you need to take into account the properties of individual species. Naturally, if you do not have sufficient experience in assembling furniture, you should pay attention to cheaper wood. The first table (chair, stool) in your life is just a kind of training in making and gaining experience.

Tabletop. Here, strength and minimal moisture absorption come first. It is on this part of the table that something constantly spills. Optimal choice– pine, larch, oak (although the latter is more expensive). Thickness – at least 3 cm.If the size of the countertop is small, then you can use wood-based slab products (OSV, OSV and the like). But only with lamination to prevent the material from swelling when liquid gets on the table surface. For example, chipboard.

IN furniture industry low-grade lumber is not used. This is not economically feasible, since pre-treatment of wood increases the duration production cycle. But when making anything, wood of lower grades, substandard wood is just right. The same pallets left over after using stacks of foam blocks or bricks.

And not just because it is free or relatively cheap. Many of the disadvantages of such wood can be turned into advantages with the right approach. For example, after coating with colorless varnish, the tabletop acquires a unique, original look.

The main thing is that the boards do not have obvious defects in the form of rot, cracks, falling knots and wormholes.

If pine is chosen for the tabletop (this also applies to many other conifers), then you need to pay attention to the location of the annual rings. These arches are called humps. The cuts of the boards show how they are oriented, and this is taken into account when laying them in a row. Samples obtained by tangential cutting are arranged alternatingly (one top down, the next one up); radial cutting - the same (with arcs in the same direction). The nuance is insignificant, but compliance with this recommendation eliminates the risk of warping and splitting of the boards.

For furniture, if you think about its durability, you should take only dry lumber. As wood shrinks, it will become deformed; This is a natural process, and its consequences in the form of twisting, warping, and bending are inevitable. Such a table will quickly become warped, and you will have to repair it. And here you need to decide whether to purchase highly dry wood or rid it of moisture yourself. The first option is simpler, but such a tree is more expensive. The second one will cost less, but there are a number of purely technical difficulties.

- Firstly, it is necessary to ensure stable temperature regime at the place where the workpieces are stored. Changes in its value will lead to uneven evaporation of moisture, which will negatively affect the strength of the tree.

- Secondly, good ventilation must be organized.

- Thirdly, and perhaps this is the most unpleasant moment - you will have to wait up to about six months, depending on the initial moisture content of the tree. But this is not a guarantee that the result will be as expected; Even this requires practice.

This once again confirms the idea that when starting to make furniture from wood for the first time, you should focus on simple table For economic needs made of cheap lumber, without pretensions to its sophistication and originality of design. For example, for a barn, garage and the like.

Options and patterns of wooden tables

It should immediately be noted that any work related to the design and self-assembly- the process is creative. There are no stereotypes in this matter, so you can only take the model you like as a basis, and everything else - linear parameters, shape, manufacturing specifics - depends on the purpose of the product and your own imagination. Here are just a few examples of what wooden tables can be like. For example, for summer cottages and small utility rooms, it is worth choosing structures whose geometry can be easily changed - folding, camping, hanging, garden, level, and so on.

Tables that are supposed to be used for eating, games, as coffee tables for installation in living rooms intended purpose, are made stationary, that is, unchangeable in size. These assemblies are more “solid”, since all articulated parts are rigidly fixed; no hinge joints.

Features of assembling wooden tables

If a person undertakes to make something, it means that he knows how to use tools, read blueprints and work with lumber. Such home handyman There is no need to learn the basics of carpentry. But it would be worth noting a number of nuances when making a wooden table. These notes will only help in the process.

Let's start with the types of connections. There are quite a few of them, but for a table that you assemble with your own hands, the ones listed below are quite enough.

On the dowels

In this case, the parts are fastened by placing them on an adhesive composition (Fig. 1 – 3).

The nuance is that to make the “cylinders” that are inserted into pre-drilled “channels”, a tree of a denser structure than the table elements is taken. This is what ensures the strength of the connections. Before installing them, chamfers are removed from the edges of the dowels and holes.

These round sticks are available for sale in any furniture showroom, several standard sizes. Turning them, even if you have a carpentry machine, is a waste of time. It is not recommended to purchase plastic dowels for the table; they are used for detachable connections. For example, frame furniture (walls, multi-level shelving, etc.).

You should not use nails to fix table elements (Fig. 4). Metal and wood differ in the degree of thermal expansion. Such a connection will not last long - it will begin to “shatter”, especially if the table is intended to be installed on the territory or in an unheated room.

On the kings

It is advisable to make such connections if the table either has to be disassembled periodically, or without this it is impossible to move it through the doorway. Although not all drawers require dismantling the structure. The most commonly used options are shown in the figures.

Bolted

Such connections are used mainly for garden furniture or those installed in extensions; for utility tables. An example is shown in the figure.

The nuance of working with fasteners

In order for the self-tapping screw to be easily screwed in and “go” in the desired direction, a hole is first made at the point of its installation using a drill with a diameter slightly smaller than the fastener leg. The main thing is to maintain the coincidence of the axial lines, that is, to prevent skew. In this case, to “plant” the screw, you can do without a screwdriver.

Features of wood processing

Everyone knows that a plane is used first, an abrasive with a large grain, and then a fine one. But sometimes it turns out that the last stage, grinding has to be done many times. Much depends on the type of wood and the degree of drying. After applying the first layer of varnish, the fibers may “stand up”. Nothing wrong with that. You should wait for the workpiece to dry and repeat its processing with abrasive. The work is painstaking and takes time. But it is precisely this method that can bring “problem” wood to ideal “smoothness.”

To eliminate the risk of injury to a person, all edges and corners of the table should be slightly rounded.

Features of external finishing

- Minor defects in the form of cracks and chips are eliminated with putty.

- Once sanding is complete, all wood dust must be removed. IN in this case An ordinary household vacuum cleaner with an appropriate attachment will help out. It is recommended that after such cleaning, wipe the entire table with a slightly damp cloth, let it dry and repeat removing any remaining dust. After this, you can safely start applying stain or varnish - there will be no “pellets” on the wood.

- You can add originality to the table not only with the help of curly cutouts, an unusual shape of the table top or legs, or a combination of textures different breeds and so on. One of the good options is artistic painting.

And finally. The work of independently making something out of wood (the same table) is just First stage mastering the skill of “designer-assembler”. Having developed technologies and techniques on wood and acquired the necessary skills, it is enough to simply switch to other materials - metal, plastic, glass. So the benefits of a wooden table made even according to the simplest drawing (besides the pleasure of work and money saved) are obvious - time not wasted.

Do garden table You can do IR yourself using scrap materials, which many will find absolutely useless. We offer you unusual ideas for the dacha, which relate to the creation of various garden furniture and tables, among others. Look at the photos of garden tables and choose for yourself best option. When implementing any idea for a summer house, you can use your imagination and make the changes you need.

How to make a garden wooden table with your own hands: photo

A wooden garden table represents the aesthetics of the natural landscape of the dacha and the ease of manufacture. Photos and photos will help you make a garden table with your own hands. detailed instructions. Before you start making a garden table with your own hands, prepare everything necessary materials and tools. Be sure to look at the photo on how to make a garden table with your own hands: they show the production process.

It's very stylish and original table, which can be used both in the garden and in the country interior. The costs are minimal, because it is based on a pallet of bricks.

You will need:

- brick pallet;

- swivel wheels with a diameter of approximately 10-12 cm;

- antiseptic stain for wood of the color you need;

- sandpaper;

- screwdriver;

- ordinary screws;

- screws for metal tiles;

- brushes

The procedure for making furniture and detailed instructions on how to make a garden table with your own hands.

Sand the tray well: first with coarse-grained sandpaper, then with fine-grained sandpaper. You can also use a grinder with a grinding wheel.

Attach swivel wheels to the bottom of the pallet. To do this, use ordinary screws, onto which put washers removed from the screws for metal tiles (since on the bases of the wheels large holes). You can directly fasten the wheels with screws for metal tiles, but then you will need a special attachment for a screwdriver.

Cover the table with an antiseptic wood stain, preferably containing wax. In this case, the table can be tinted to resemble walnut, rosewood, oak, pine, larch, or use a transparent antiseptic to only highlight the structure of the wood without changing its color.

Please note: not all pallets are the same! They are different sizes and with different intervals between the slats. Choose a pallet that suits you best.

Round garden tables made of wood and their photos

If you have an old round garden table, don't rush to throw it away! Of course, it has absolutely no appearance and is broken, but it is a real find for your garden. In its new guise it will decorate not only a relaxation corner in the garden, but also a country house.

Garden tables made of wood will go with many styles, as their decor is universal.

Look at the photo of garden tables with similar design options:

You will need:

- old wooden table;

- wood putty;

- old tiles of various colors or broken tiles;

- white facade paint;

- tile adhesive;

- white grout for joints;

- priming;

- copper and gold contours for glass;

- putty knife;

- sponge.

Manufacturing procedure

Fill cracks and gouges and sand the table with fine-grit sandpaper, then prime everything except the tabletop. Paint the table with white paint (except the table top).

Wrap up tiles into a piece of drape or other dense soft fabric and break it with a hammer. Apply an even layer of tile adhesive on top of the tabletop and cover the surface of the tabletop with tile fragments. Trim the edges with a trowel. When your mosaic has dried a little, wipe the surface with a sponge soaked in water to remove any traces of glue from the surface.

After the glue has completely dried, treat the seams between the pieces of tile with white grout.

Paint the sides of the table top with white paint, and then decorate them, as well as the legs of the table, with gold and copper glass outlines.

Plastic garden table

Typically, garden furniture is made of plastic, wood, rattan, presented in soft natural colors.

Typically, garden furniture is made of plastic, wood, rattan, presented in soft natural colors.

However, if a bright multi-colored “character” appears in the garden, especially one made of colored glass, then all attention is immediately drawn to it.

And it is made from an old broken flower stand, a lid from a metal barrel and ordinary round glass.

However, all these elements can be replaced with scraps of colored plastic.

So, let's look in more detail at how to make a plastic one. dining table with your own hands.

You will need:

- metal part from a flower stand;

- lid from a metal garden barrel;

- round glass with a diameter of 50-60 cm;

- a piece of rubber seal for windows;

- paper;

- pencil;

- copper circuit for glass;

- copper acrylic paint;

- white paint for rust;

- acrylic primer;

- means for obtaining patina;

- paints for glass painting.

Manufacturing procedure

On a piece of paper, draw a circular pattern in the Moroccan style. Then increase the pattern to the right size using a photocopier. Place the pattern under the glass and outline it with a copper outline. Dry the circuit thoroughly for the time recommended by the manufacturer (usually 8 to 24 hours).

Paint the interior parts of the ornament with bright stained glass paints. It is important that the paints you use are distributed evenly within the outlined area, so before painting the tabletop, practice on a small piece of glass to determine the right amount of paint for the fragments. Dry the finished painting well.

If desired, add additional ones to the finished painting. decorative elements copper circuit.

Paint the barrel lid with white rust paint. Now let's move on to the main part of the tabletop.

Prime the stand piece and paint it copper acrylic paint, then apply a patina product in some areas.

When the “foot” of the table is dry, glue small pieces of window seal onto the parts that will be in contact with the tabletop. This will allow her to hold on well.

Assemble the table: place the painted glass on the lid of the barrel, and place this “tabletop” on the foot.

DIY ideas for a garden and cottage using scrap materials: photos and descriptions

Further on this page you can see ideas for a summer house made from scrap materials and photos of the process of their implementation in practice. We necessarily accompany all ideas for a garden and dacha with your own hands with photos from different angles so that you can clearly see the whole creative process.

Folding garden table

Try making a universal folding garden table for your utility room. It looks beautiful and saves space. And most importantly, it is very convenient and will help you maintain a small utility unit in perfect order: everything is in sight and nothing gets lost.

Try making a universal folding garden table for your utility room. It looks beautiful and saves space. And most importantly, it is very convenient and will help you maintain a small utility unit in perfect order: everything is in sight and nothing gets lost.

You will need:

- a piece of edged pine board measuring approximately 60 X 20 cm;

- two ready-made wooden fastenings for shelf;

- light yellow façade paint;

- red acrylic paint;

- small glass jars with screw caps;

- screws;

- screwdriver or screwdriver.

Manufacturing procedure

Sand the board and paint it light yellow.

Decorate the ends of the board with a simple ornament using red paint.

Paint the lids of the jars with red paint.

Attach the jar lids to the board at regular intervals using small screws.

Hang the finished shelf on the wall of a utility room or workshop using ready-made fasteners (the covers should be on the underside of the shelf).

Fill the jars with screws, nails, small fasteners, staples, nuts and other small household items and screw the jars to the lids.

You can decorate jars with simple painting, applique and any other methods.

Interesting ideas for your dacha, home, garden and vegetable garden with your own hands with photos

And now we offer interesting ideas for a dacha and garden with your own hands in relation to other interior items necessary for the household.

And now we offer interesting ideas for a dacha and garden with your own hands in relation to other interior items necessary for the household.

This will be a comfortable seat on which you can relax after gardening. All our interesting ideas for a summer house and garden are accompanied by photos and can be implemented using various available materials.

Make a garden ottoman from old car tires. There are practically no costs, and the effect will exceed all expectations. This ottoman is not a simple one, but an ottoman-chest. You can store garden items in it. This will definitely not happen to anyone!

You will need:

- two old car tires one diameter;

- thick plywood;

- beautiful textiles of your choice;

- façade paint that matches your fabric in color;

- white spray facade paint;

- “liquid nails” or silicone sealant;

- construction stapler;

- jigsaw

Manufacturing procedure

Cover both tires with white spray paint, dry. Then paint both tires with light green paint, in a thicker layer, and dry.

Lay the tires one on top of the other, fastening them with liquid nails or silicone sealant. To do this, apply “dotted” small portions of any of the products in a circle on the surface of the lower tire.

Cut a circle out of plywood with a diameter slightly smaller than the diameter of the tire. Cover it with fabric and secure the fabric with a stapler.

Place the fabric-covered circle on the tire base. There you go! The seat is removable, so inner part The ottoman can be used as a place to store small items.

The paint color of the tires and the color of the seat can be anything, depending on the style of your garden and the color of other garden furniture. In any case, the ottoman will look impressive

Garden furniture: tables and benches

Garden tables and benches are indispensable attributes of a cozy and comfortable country life, in which it is possible to enjoy privacy in a shady corner of the garden.

Garden tables and benches are indispensable attributes of a cozy and comfortable country life, in which it is possible to enjoy privacy in a shady corner of the garden.

How garden furniture and tables are made, you could already fully learn from the examples published above. And now we propose to make an exclusive design of a garden bench with your own hands.

A garden bench is not just a necessary thing, but a very necessary one.

It’s so convenient to care for plantings and weed, not on your knees, but sitting on a bench, especially one as beautiful as this one. Even if it stands just like that, it is already garden decoration, no worse than any figure.

Add green paint to the pictures: add branches and leaves.

Add accents with gold paint: make painterly strokes on the drawings, emphasizing the lines and details.

When the bench is dry, cover it all, along with the pasted pictures, with a clear or slightly tinted wood preservative.

If desired, the bench can be slightly tinted with blue-gray acrylic paint, creating the effect of old wood.

We will send the material to you by e-mail

Not everyone likes to buy ready-made products for home use. The soul of some people requires creative and practical self-realization. The editors of the online magazine website invites those interested to learn how to make a wooden table with their own hands, what is required for this, and whether there are any pitfalls in such work.

Beautiful wooden product for the kitchen or living room, made with love

Professional carpenters are unlikely to find our step-by-step recommendations, but for novice amateurs the advice will come in handy. First, let's look at what products you can make with your own hands from wood.

Of course, the more skills a person has, the more complex the model he can make. But to build a table with your own hands from wood, there are ready-made drawings and photos to help beginners.

How to choose a material for making your own wooden table for home and garden

What to make from dinner table with your own hands? Best of all - made of wood. The most pliable wood for a new master will be pine. Products made from poplar will look more solemn. For the street you can take mahogany.

If you want a simpler option for your home, then you should consider laminated chipboard with optimal thickness at 25-35 mm. Can be taken on the tabletop wooden boards, birch plywood with a thickness of 35 mm. Legs can be made of metal or wooden beam(about 50 mm thickness).

In order not to make a mistake with the amount of material, a preliminary drawing of the future structure is made with precisely specified dimensions.

Advice! The suitable height of the product varies between 750-800 mm.

Related article:

DIY wooden furniture: for the garden, children's room, kitchen, bathhouse, garden, gazebo; How to restore pieces of furniture, useful tips and recommendations from experts - read in our publication.

What tools are needed to make a wooden table with your own hands?

It doesn’t matter what shape the future table will be: working with wood requires a certain set of tools. You can't do without a jigsaw, and it will be much easier to work with an electric model. To secure all structural elements, use either a drill with a multi-stage drill for holes, or confirmations. To polish the product to perfection, you need a special attachment for a drill.

For greater fastening strength, the tools include wood glue.

How to make a wooden table with your own hands - step-by-step instructions

We have selected four types of structures that can be made on your own, even with a minimum of carpentry skills. We invite you to learn about the stages of manufacturing a round and rectangular table, a coffee table and a model for garden gazebo.

Making a wooden round table

It is easiest to make a round table top and a connecting ring from or with dimensions of 1500 × 1500 mm and 1280 × 1280 mm. You will also need two laminated chipboard strips (1110 × 120 × 25 mm). We will make the legs from four wooden blocks measuring 120 × 50 × 750 mm.

How to make a countertop

How to draw a circle perfectly straight? Place your own thumb on a sheet of plywood in the center with a string and pencil tied to it. The length of the rope from the base to the top should coincide with the radius of the future tabletop. Holding your finger in one place, draw a circle around the full length of the rope with a pencil. All that remains is to cut it out with a jigsaw.

The underframe circle is cut out in the same way.

Making legs

A round table made of wood or chipboard will look charming if you do everything consistently. You won’t have to bother with the legs if your plans aren’t too original. The bars are divided into 4 parts according to the desired size of the table height minus the thickness of the tabletop. First, one leg is cut off, and the other three are aligned along it.

All processing grinder is carried out immediately.

Advice! You shouldn’t rush into sanding, as the first coat of varnish will reveal all the imperfections.

Assembly of the structure and processing of the finished product

Assembly is carried out in stages. First, align the planks groove to groove. Then the crosspiece of the planks is connected to the legs with confirmations, as in the figure below:

If you want to make the structure stronger, before connecting the legs to the tabletop, coat their upper base with glue.

Advice! Nails are not used in such work: a self-tapping screw or confirmat can be unscrewed without problems, and the connections will be much stronger.

Making a rectangular wooden kitchen table

The rectangular design is classic and very useful in everyday life: it is convenient to cook on such a table and you can comfortably dine at it.

How to make a countertop

A wooden tabletop for a table is made either from a whole sheet of plywood, or from individual edged boards processed to perfect smoothness.

Having fastened the boards with screws and glue, they begin to make the frame.

Making wooden legs for a table and frame

At the heart of the quadrangular models is a frame. It serves to securely fix the legs, ensuring the stability of the entire structure. The tabletop is turned over, a depth of 3-4 cm is measured on each side and the measurements are transferred to the boards. As a result, you will need two boards of shorter length and two longer.

The frame is made of four elements: according to the approximate ratio, these are two boards of X cm and two of 2X cm. They are connected to each other with an overlap one by one, building a rectangle. In order not to break the 90° angle, use any board when working with a screwdriver: it is used to press the structure while tightening the screws.

As soon as the frame box is ready, they begin to make the legs. You can take ready-made balusters for the table, buy metal supports, or cut them out of bars according to the desired length according to the drawing.

Both the frame and the legs are subject to mandatory thorough sanding!

Product installation and final finishing

The frame is screwed to the tabletop with glue or self-tapping screws. Then the product is turned over and the legs begin to be attached.

Important! It's better to make holes for the screws in advance. This eliminates the possibility of the wood splitting.

Why don't they use nails and a hammer? Not everyone has the skills to work with a hammer - it’s not only dangerous to hit your finger. Overdoing it can easily damage the wood by splitting it. Confirmations and self-tapping screws hold the tree much more firmly.

As soon as the leg is secured, the angle is immediately checked: there should be no deviation from 90°. The operation is repeated with other legs. You can attach the legs directly through the tabletop, but this will affect the aesthetic component of the product.

Related article:

: photo best ideas. What can be made from pallets for an apartment, office and cottage; rules for selecting and processing pallets; Master classes on making a table, sofa, bench, armchair and shelving - read our publication.

Making your own wooden coffee table

Not only beautiful element interior, but also useful. There is no need to look for a visible place to put a book, gadget, glasses, or TV remote control. Such necessary structures are made from different materials: metal, glass, plastic, chipboard, wood. But let's leave other materials alone and concentrate on working with wood.

Choice wooden table top for the table depends on the expectations of the owner of the product. Some people want something massive, while others prefer lighter options. Let's stick to a simple solution.

We purchase five boards 30 × 150 mm and process them to perfect smoothness. Immediately saw off the required length onto the tabletop: you should get 6 identical sheets. We take four bars for the legs, 6 shorter pieces for the lower tabletop, and 4 narrow slats for the frame.

| Illustration | Description of action |

|---|---|

| To brush wood, use a grinder with a brass brush attachment. The procedure will expose the structure of the wood, giving the product a special flavor. |

| We go back and forth along each board on the side that will be the front. |

| We treat the wood with fire. The flame is gradually moved from place to place: the board will acquire a beautiful darkish tint. The procedure will completely destroy unnecessary soft wood fibers. We actively wipe the entire surface with a felt boot or a piece of felt. |

Let's start the assembly process small table with your own hands made of wood.

- The lower and upper tabletops are laid on work surface wrong side towards you. The boards are laid tightly together, gluing them together. Once the boards have set, slats are attached to the top tabletop. They will serve as a frame and fastening element. They can be glued or screwed with self-tapping screws. The self-tapping screw is screwed into the center of the slats into each of the boards.

- The legs are screwed to both the tabletop and the slats. You can use furniture corners.

Video: the process of making a coffee table from wood

Making your own wooden table with benches for a gazebo

It's time to take the time and build a wooden garden table.

It's best to take boards standard sizes. At a hardware store, you can purchase studs (suitable for a length of 16 cm) and washers (24 pieces). For a garden gazebo, long nails (8 cm) will do.

Whether to paint a product or simply varnish it is a matter of taste.

To make it more convenient to stay in a recreation area, gazebo or dining area in the garden, you can make a table for your dacha with your own hands. It is also useful for work: replanting flowers or sowing seeds in a seedling box, sorting herbs or mushrooms at the table. No need to buy in store plastic products, if you can independently assemble a country table from wood or scrap materials.

Building a table for a summer house is very necessary work, and using wood as the main material will help make it durable and light.

How to make a wooden table?

First you need to determine the dimensions of the product depending on the area in which it is planned to be placed. There should be enough space left in the gazebo or seating area so that you can move freely around the table and place chairs or benches. Bulky furniture does not fit well into the interior of the gazebo or summer kitchen, therefore the main requirement for it is harmonious dimensions. But a wooden table placed on an open lawn can be large enough to accommodate everyone.

To make furniture for a gazebo or kitchen you will need:

Figure 1. Scheme of fastening the legs of a wooden table.

- 5x5 block or ready-made figured balusters;

- board 2.5-3 cm thick;

- screws, furniture corner;

- screwdriver, drill;

- hacksaw or electric saw;

- plane;

- measuring instrument, construction square;

- furniture varnish, brush.

Before assembly, all parts of the future piece of furniture must be processed with a grinder or plane and sandpaper. Parts prepared for the table must be smoothly sanded on all sides.

Making a table begins with assembling the frame for the table top. This is a structure of 2 longitudinal and 2 transverse boards on which the legs are attached. The legs can be made from a regular block by slightly planing the lower end of each section with a plane and chamfering. If you purchase turned balusters for stairs at a hardware store, you can create a table with curly legs for an interior in the style of shabby chic or Provence. Optimal height- about 75 cm for a dining table, but for furniture with other purposes it can be chosen at will.

When assembling the frame, it is necessary to take into account that the tabletop should protrude beyond it by about 3-4 cm around the entire perimeter. Therefore, if you purchased ready-made panels for a tabletop of a certain size, the frame must be calculated so that its length and width from one outer corner to the other are 6-8 cm less than the same dimensions of the tabletop.

Assembly is carried out in several stages:

Figure 2. Scheme of strengthening the folding table.

- Fasten the legs in pairs using crossbars. Fastening can be done as shown in Fig. 1. In this case, screw in the screws at an acute angle to the plane of the crossbars from the wrong side. To prevent the board from splitting, you must first make holes into which the fasteners will then pass. The ends can be additionally lubricated with wood glue for joint strength.

- Install the long sides of the underframe in the same way, connecting 2 pairs of legs together. Fastening to the boards can be done differently (using a steel angle, attaching it to the inner surface of the boards and beams or balusters with self-tapping screws). Another way is to attach the block to the plane of the board, aligning its ends with the outer corners of the legs. Then the boards of the long sides need to be placed on the block and the end, screwing the screws into the leg through the holes in the plane.

Attaching the table top to the base can also be done in different ways: on a corner, corner rail, self-tapping screws. In the first case, you will need to screw the corners from the inside of the underframe and tabletop so that one side of them is on the leg or board of the frame, and the other is on the panel of the tabletop. To attach to a corner rail, you need to screw 3x3 cm pieces of timber onto internal sides frame boards. Secure the tabletop to the rail by screwing self-tapping screws through the holes in the bar. The length of the screws must be selected so that they do not go through outside countertops. The easiest way is to drill holes on the front side of the shield and screw self-tapping screws through them into the end of the leg.

After assembly, all visible traces from screwing in the screws should be puttied and sanded after drying. Eliminate cracks and other defects on the surface of table parts in the same way. Coat the finished product with furniture varnish in one layer. After the varnish has dried, sand it with fine sandpaper and carefully remove dust. Apply 2 more layers of varnish, allowing to dry.

Return to contents

How to make a folding desktop for a summer house?

If the table is not needed every day, but is used only from time to time, it can be made folding.

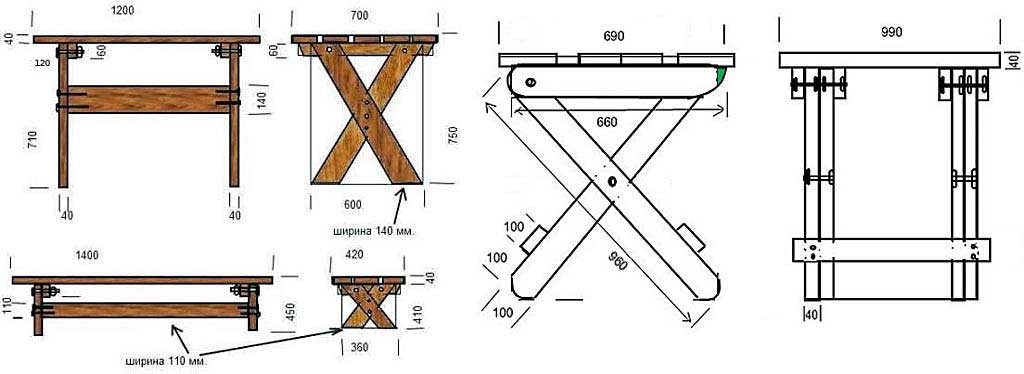

Figure 3. Diagram of a table with cross-shaped legs.

For such furniture it is not necessary to purchase expensive wood; you can make do with improvised means and make it from wooden pallet. In addition to this, you will need:

- small loops;

- self-tapping screws with a hook head or eye bolts – 5 pcs.;

- metal chains or strong cord;

- screws, screwdriver;

- sandpaper.

Strengthen this folding table(Fig. 2) can be directly on the wall wooden structure or gazebos. You can use an additional shield on which you can hang working tools.

For manufacturing you will need a pallet with carefully polished surfaces. Secure one side of the loop to the ends of the planks adjacent to the wall or panel and attach the pallet to the vertical. To hold the tabletop, screw 2 eye bolts into it and the shield, fasten chains or a strong decorative cord to the rings.

To hold the tabletop upright when the table is not needed, you need to fasten a short piece of chain or a loop of cord in the middle of the side farthest from the wall. Screw in a self-tapping screw with a ring or a hook in the appropriate place on the shield.

A DIY kitchen table is both an opportunity to save money and a way to provide a kitchen unique furniture, fits perfectly into the available space. However, it is important to correctly determine the dimensions and shape of the future structure.

How to make a wooden dining table

A table made of solid wood is beautiful, natural and, as a rule, expensive. But you don’t have to buy such a table, because you can make it yourself with no less quality and for much less money.

So, to make a dining table with your own hands you will need:

- 4 things. baluster legs for the table, 73 cm high and not too thin;

- For the tabletop: 4 dry edged wooden boards 1 m long (for a table 60 cm wide);

- For the frame: 2 boards 80 cm long and 2 boards 40 cm long.

Prepare the tools: plane, grinder or grinder, jigsaw for cutting boards, circular saw, drill (with 8 mm drill bit), screwdriver, sandpaper, self-tapping screws (30 mm), wood glue, dowels, clamps (preferably). And, of course, a pencil, tape measure, gloves and safety glasses will come in handy.

For finishing The table will need varnish, stain or paint along with a primer. First we'll make the tabletop. To do this, you need to adjust all 4 boards as accurately as possible to the same length - 100 cm. If your boards were not sawn on a sawmill, then they also need to be trimmed in width and thickness. Then they need to be carefully sanded with a plane. The better you sand the wood, the smoother the countertop will be. Finish the edges well so that the boards fit together as tightly as possible.

We will connect the boards not with screws and nails, but with glue and dowels (chops). To do this, we make identical marks on the edges of all boards in increments of 10-15 cm and drill holes for the dowels with an 8 mm drill. Then we sand the edges and apply wood glue to them and into the holes made. Now we drive the chopsticks treated with the same glue into the holes and connect all 4 bars one by one. We remove excess glue on the surface with sandpaper and sand it, as well as all edges, with a plane. At this stage you can walk along the tabletop metal sponge to give the wood texture.

So, the tabletop is ready. Now you need to fasten the legs and make a base for it.

To do this, you need to evenly fasten the balusters with short transverse boards with glue and screws. The glue dries for at least 12 hours.

We attach the legs to the long crossbars and drill holes in them in order to install the tabletop later.

After the glue in the frame has dried, you can begin installing the tabletop on it (frame).

If you want to make the table longer and wider, then you need to strengthen the table with two additional cross bars, as shown in the photo.

So, the table is almost ready, all that remains is to treat it with varnish or stain, or paint it, having previously primed it.

What color should I paint the table? Based on personal preferences and the color of the rest of the furniture. Below is the most versatile option - the table top and legs are covered with stain.

You can see the main mistakes in staining wood with your own hands in this video.

If you like gloss, then the surface of the table can be covered with stain, and on top - with varnish (example in the photo below), or simply coated with varnish.

You can paint the legs white and cover the tabletop with stain to get a design like the one in the next photo.

How to make a kitchen table from chipboard

DIY kitchen table from laminated chipboard- This is a practical and budget solution. These countertops are covered with decorative plastic that is abrasion-resistant. In the typical version, the dimensions of the tabletop sheet are 3000x600x36(26) mm, but today it is not difficult to purchase a sheet of chipboard cut to the required dimensions or negotiate with a furniture workshop for the sale of suitable trim.

You will also need:

- Connecting and end strips;

- End edges;

- Ties.

Even if you purchase a countertop of suitable dimensions, you will need to additionally process the ends - this will make the result more attractive and also protect the base from moisture. For these purposes, you can use a special furniture edging based on polyvinyl chloride or glue an edge tape. The option with edging is considered more practical for the dining table and suitable for home craftsmen.

For kitchen table You will also need appropriate supports - you can buy the legs separately or give preference to a ready-made base. It all depends on which option your drawings provide. The most common option is round legs D = 60 mm and height 71 cm. They can be collapsible, height adjustable, and also vary in design - matte, painted, shiny.

In our case, these will be chrome-plated shiny rod legs with a diameter of 60 mm, as well as a tabletop made of white laminated chipboard with a thickness of 36 mm and a white plastic mortise T-shaped edging with girths matched to it.

So, how to make a dining table with a chipboard top:

- Markings are applied to the material according to the drawing. The corners must have a radius of 60 mm or more.

- The tabletop is shaped using a jigsaw.

You should use a saw with reversible teeth, otherwise the plastic coating may chip. First, the corner of the chipboard is cut with a jigsaw with a margin of 2 mm, and then it is finally rounded with a grinding machine.

- The groove for the furniture edging is milled.

- The edging is getting stuffed. Before this, the ends of the product must be coated with silicone sealant. The sealant is placed both in the edging and on the top edge of the tabletop. A rubber mallet is used to fill the edging. After which the excess sealant is removed.

- The legs are attached. To do this with reverse side The tabletop is marked with a pencil. In most cases, the legs are placed 100 mm from the edge.

To fasten the holders, self-tapping screws with a countersunk head about 20 mm long are used. After this, the legs are put on the holders and secured with a hex key - that’s it, your new table is ready.

How to correctly determine the dimensions

Using the principles described above, you can make tables larger or smaller in length and width. How to choose the optimal size for your family?

If we're talking about O standard kitchen dimensions from 6 to 8 squares, then the drawings will show a typical design with a height of 750 mm and a perimeter of 800 * 500 ... 1200 * 600 mm.

A DIY dining table should be designed for a certain number of people. Usually it corresponds to the number of residents - 3-9, but a couple of free places are still added for guests. For large companies good decision will become .

Calculations are in progress in the following way: the number of people is multiplied by 60 (“working” perimeter per person). As for the width of the tabletop, we follow the recommendations of experts - its optimal values are from 800 to 1100 mm. Narrow tables are difficult to serve, and wide tables are uncomfortable for those sitting.

If you decide to make the kitchen table oval (round) with your own hands, then you will have to calculate the circumference - diameter * 3.14.

Form selection rules

The shape of the kitchen table plays a significant role in the perception of space. Universal design - rectangle or square with right angles. It is balanced and can be installed close to the wall or in the center of the room, saving space.

Oval models are also quite comfortable and beautiful, but they are not very spacious - the largest product will accommodate no more than 8 people. In addition, they require large areas - more than 8 square meters. meters, because you can’t put them against the wall.

It can also be called a universal and traditional option, suitable for both very large and large kitchens. But it has less capacity than a rectangular table.

The best option is rectangular table with rounded corners. We have already described above how to make just such a table from chipboard with your own hands.

Rules for caring for furniture

After the dining table is made, you will need to take care of the long service life of the product.

Thus, furniture made of wood, polished and varnished, needs careful care, as it can be easily scratched. In addition, there may be traces from contact with hot water. For basic wood care, a universal polishing compound is selected.

If we are talking about a countertop made of MDF or chipboard with a plastic coating, then caring for it is not difficult and involves regular washing with detergents.

Do not forget that kitchen furniture need to move away from heating devices and from the walls bordering the street. Harmful to wooden furniture There will also be direct sunlight.