How to make a homemade snowmobile on tracks with your own hands? How to make a caterpillar from a tractor tire.

When operating in off-road conditions, tracked vehicles have undeniable advantages over wheeled transport due to its all-terrain qualities, allowing it to overcome deep loose snow, soggy arable land or rocky ford.

The popularity of tracked vehicles among household users is so great that many home craftsmen independently “convert” their wheeled vehicles into homemade ones - tracks made from scrap materials.

One of the retrofitting options is to use old tires from MTZ tractors, allowing significantly increase cross-country ability personal auto and motorcycle equipment at minimal financial costs.

For a tracked vehicle of any purpose, be it a tank or a snowmobile, forward motion is provided by a tracked propulsion unit (CT).

It uses two motivating factors:

- torque Mk, transmitted from the engine/power drive to the drive wheels;

- adhesion of tracks to the ground.

A caterpillar or caterpillar chain of a main engine is a link structure, which is a continuous continuous belt or chain.

For full traction with the ground surface, the caterpillar equipped with relief protrusions, serving as active lugs.

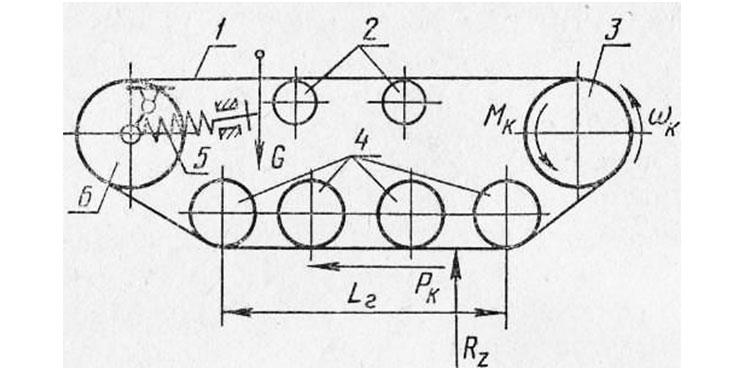

The crawler principle is illustrated kinematic scheme work of the main engine located below. The following positions are indicated on the diagram:

- pos. 1 – caterpillar;

- pos. 2 – support rollers that prevent the track belt from sagging;

- pos. 3 – drive sprocket (drive wheel), which converts torque from the engine into traction force necessary for the forward movement of the machine;

- pos. 4 – support rollers, ensuring full contact of the track belt with the surface of the ground support;

- pos. 5 – shock absorbers;

- pos. 6 – guide wheel, which serves to direct the forward movement of the machine and transfers part of its weight to the ground.

Movement according to the caterpillar principle carried out as follows:

- Torque Mk is supplied to the drive sprocket (item 3).

- The rotating sprocket rewinds the continuous track belt/chain (item 2).

- The caterpillar (item 2) is in close adhesion to the support surface (soil, loose soil, etc.). It is affected by:

- force R z – reaction of the supporting surface, which the caterpillar transmits to the vehicle frame;

- tangential reaction of the ground support P k.

The rewindable track belt/chain is continuously laid in the direction of forward movement of the vehicle on the surface of the ground support under the road wheels, creating for the wheels of the vehicle path with lower resistance to movement than on soft ground.

During movement, the caterpillar belt rises from the supporting surface and transfers the pushing force to the vehicle frame.

The specific pressure on the support (soil) along the length of the track is uneven - increased in the area of the drive sprockets, decreased in the front part in the area of the guide wheel (item 6). The maximum pressure on the ground from the main engine is in the area of the road wheels (item 4).

Advantages of homemade diesel engines from MTZ tires

Thanks to the continuous placement of the caterpillar belt under the machine's rollers, a large contact area of the belt with the ground, significantly reducing the average pressure of the machine on the soil.

The range of average pressure on the ground of equipment with deep pressure is from 11.8 to 118 kN/sq.m (from 0.12 to 1.2 kgf/sq.cm), which is significantly lower than the pressure of a human foot.

Such low performance pressure ensures protection of equipment from immersion in the ground, swampy soil or snow. By varying the size of the surface area in the contact zone of the track with the support, an optimal ratio of the vehicle's cross-country ability with its traction force for towing cargo is achieved.

When equipping vehicles with caterpillar tracks, homemade DIYers use transport belts or tires from automobile and tractor wheels.

The photo below shows homemade all-terrain vehicle on conveyor belt tracks reinforced type 250 mm wide. Grousers with a height of 25 mm are used.

All-terrain vehicle made from a conveyor belt:

For most craftsmen, the preferred source materials for the manufacture of diesel engines are old tires from MTZ tractors of various models.

The main advantages of MTZ tires, as a source material, and the tracks themselves made from these tires include the following factors:

- Availability old MTZ tires. Quite often, after dismantling, they are stored in the depths of the utility yards of enterprises, cluttering the territory.

- The tire is a closed continuous structure, does not require sewing the ends tapes.

- On a tracked platform made from a tractor tire no need to increase lugs, since the tires have a pronounced tread pattern of the factory design.

- MTZ wheel tires have high strength and wear resistance, ensuring reliable, trouble-free operation of the caterpillar belt on soils containing sharp stones.

- Versatility applications - you can select tires for all types of tracked vehicles, including measures to modernize equipment or increase the width of tracks.

- Recycling of used tractor tires solves the most important problem of recycling dismantled wheels - the possibility of their reuse.

From shortcomings When working with tractor tires, two circumstances are noted:

- limited fixed track length, determined by the size of the tire blank;

- the need to double two tires when installing a track with a width exceeding the width of one blank tire.

Requirements for converting equipment to caterpillar tracks

The picture shows simplest in design homemade cart with tracks made from tires.

The re-equipment of equipment for diesel engines is carried out exclusively for utilitarian reasons of pragmatic owners of wheeled vehicles or motor vehicles who wish improve all-terrain qualities their "helpers".

For all models of equipment intended for driving in field conditions, the market offers serial versions of industrially manufactured gas engines.

However, all this costs a lot of money, and tires free or very cheap.

Many equipment users manage to independently, in a home workshop, make tracks from tractor tires, install them on their machines and successfully operate in off-road conditions.

Regardless of the type of vehicle or motor vehicle, technicians take into account the following factors:

- To install the main engine mechanisms, it is necessary to equip special frame structures increased strength and rigidity, capable of withstanding increased weight and dynamic loads.

- When using improvised means, many craftsmen use pneumatic wheels as tensioners, as well as a pair of driving and driven wheels. The tape is put on the flat tires, which are then inflated, creating the required track tension.

- The owner of the equipment must clearly determine the purpose of the machine in order to select optimal sizes width and length of the caterpillar track.

- Taking into account the increase in weight and traction loads on the engine after installation of the main engine, it is necessary to optimize the correspondence between the maximum engine power and the width of the track. Otherwise the engine breaks down quickly.

When choosing the ratio of engine power and belt width of a homemade tracked installation you can be guided by price list data on all-terrain vehicles equipped with serial tracks.

Below we will consider the categories of machines that are most popular among craftsmen when re-equipping to crawler.

Main categories of popular equipment equipped with gas engines

The list of models of household vehicles and motorcycles operating on loose snow and marshy soils is unusually wide.

The names of the machines themselves, accepted in everyday life, indicate their field of application.

Snowmobiles

This vehicle designed for movement on loose snow cover.

Unlike the anglicism “snowmobile”, which denotes any vehicle adapted for movement on snow (snowmobiles, all-terrain vehicles on tracks and pneumatic wheels, etc.), in Russia a snowmobile is only called means of ski-caterpillar movement(rear main engine, in front - skis instead of the front wheel) with motorcycle-type controls.

For utilitarian snowmobiles, the engine power is 30-40 hp, the track width ranges from 38 cm to 50 cm and even 60 cm.

Accordingly, if a master sets his task to create a machine for moving on virgin snow with a load, then he should focus on these indicators.

Similar parameters must be maintained when creating so-called snow and swamp-going vehicles.

If the master needs make a faster snowmobile(like sports ones), then the width of the tire track can be reduced.

If the master needs make a faster snowmobile(like sports ones), then the width of the tire track can be reduced.

The weight loads of a high-speed vehicle are much lower than those of a cargo utility vehicle.

The picture shows a motorcycle-based snowmobile equipped with a homemade 23 cm wide track cut from an excavator tire.

Otherwise, a homemade snowmobile track is made with your own hands according to the basic principle.

All-terrain vehicles

They are commonly referred to as any vehicle capable of driving off-road and even overcome water obstacles.

Types of all-terrain vehicles industrial production plenty:

- SUVs;

- swamp walkers;

- amphibians;

- tracked tractors and conveyors;

- ATVs;

- ATV category vehicles, etc.

Their cost not everyone can afford it, therefore, in home workshops they prefer to create their own exclusive products, “re-shoeing” their cars with tracks from tires made by themselves for an all-terrain vehicle.

Depending on the engine power of the vehicle, wider blades can be allowed.

For homemade all-terrain vehicles with a 40-70 hp engine. and a small weight load, a tape width is sufficient 30-40 cm.

For vehicles based on UAZ vehicles with an engine of 110-150 hp. track width required 40 cm with support rollers (6 pcs.) and support rollers (3 pcs.).

For vehicles based on UAZ vehicles with an engine of 110-150 hp. track width required 40 cm with support rollers (6 pcs.) and support rollers (3 pcs.).

Naturally, the profile height of a tractor tire will not be enough to overcome a water obstacle, it is necessary to install high lugs.

The figure shows an all-terrain vehicle based on the Oka vehicle with a caterpillar track made of tires.

Walk-behind tractors

Represented by numerous mobile devices based on a single-axle chassis. Converted for the State Duma homemade options walk-behind tractors are widely in demand among rural residents and owners country houses or summer cottages.

The motivation for independently re-equipping units, bypassing the purchase of serial tracks, is obvious.

The cost of the NEVA wheeled walk-behind tractor does not exceed 1000 dollars. USA, while the most simple machines, adapted for movement on snow, are estimated at 5-10 thousand dollars. and higher.

The drive power of the walk-behind tractor (5-8 hp) is quite enough to be successfully used as an all-season vehicle

Motorcycle dogs

Motorized towing vehicles, nicknamed motorized dogs in everyday speech, are a mechanical coupling of a sled with a towing vehicle on a main engine. The driver and cargo are placed in the sleigh.

Serial models are produced in a wide range of drive power (from 6 to 30 hp) and are equipped with a motor made of rubber-metal tape up to 60 cm wide.

Home craftsmen usually make towing vehicles based on a 15 hp engine from improvised means, installing tracks from tires 500 mm wide.

Home craftsmen usually make towing vehicles based on a 15 hp engine from improvised means, installing tracks from tires 500 mm wide.

Such homemade motorized dogs capable of transporting sleds with a load of up to 700 kg, reaching speeds of up to 40-50 km/h.

Most often, a homemade caterpillar for a motorized dog is made from a tire to save money.

The photo shows a homemade motorized towing vehicle based on a walk-behind tractor.

Algorithm for making a caterpillar belt with your own hands

The caterpillar track for any model from the above categories of equipment is made from tires of various sizes corresponding to the selected design. Let's look at how to make a caterpillar from a tire step by step.

The work on tape production is unified and follows a general algorithm.

Special knowledge is not required when making a caterpillar from a tractor or car tire, however you can’t do without certain plumbing skills.

The process of forming a caterpillar track from an MTZ tire consists of several stages:

- Select a tire with a slightly worn tread.

- The path is being cut for the caterpillar using a sharpened shoe knife. Working with a sharp knife is dangerous and requires increased caution and attention.

- To cut rubber better, it is recommended to use a knife periodically moisten with soapy water.

- Cutting with a knife can be successfully replaced jigsaw, protecting yourself from possible injury.

- Both sides are cut off tires.

- Excess material is removed from inside the tire.

The criterion for quality work is an even cut without frayed edges of the resulting tape.

So the track element is ready to use:

Video on the topic

You can see a homemade snowmobile track made from a tire in action in this video:

Conclusion

Making homemade tracks for converting equipment to caterpillar tracks is a very popular way to expand functionality machines at minimal cost.

The use of dismantled old tractor tires for HD helps to solve the problems of recycling old tires without the use of traditional waste processing methods - burning, grinding, chemical treatment, etc.

In contact with

To increase the throughput capacity of a walk-behind tractor and use it as an all-terrain vehicle or snowmobile, you can equip it with tracks. They can be purchased ready-made, but they are expensive, and it is not always possible to choose the right option for your walk-behind tractor. There are several ways to make a caterpillar for a walk-behind tractor with your own hands.

How to make a caterpillar on a walk-behind tractor with your own hands

If you wish, you can independently modify your walk-behind tractor, turning it into a tracked all-terrain vehicle or snowmobile. The main rule is that you should consider what work the tracks are intended for in order to choose the right material, because they must be not only durable, but also extremely light.

Having available materials and correctly calculating the length of the caterpillar, you can make it yourself using simple improvised means.

First of all, you need to equip your walk-behind tractor with an additional pair of wheels. A caterpillar track will be put on each side pair.

The length of each of the two goosenecks will be equal to the circumference of one wheel and the distance between the axles of each pair of wheels, multiplied by two.

Important: the wheels on the walk-behind tractor must be the same diameter.

Materials for homemade products can include:

- conventional conveyor belt and bush-roller chain;

- car tires;

- belts and chains.

So, let's look at a few options self-made goose, depending on the material used.

From a conveyor belt

This method is the simplest because it does not require a large number of special tools and auxiliary materials.

- When choosing a tape for a caterpillar, give preference to a strip whose thickness will be at least 7 mm - after all, it bears a fairly large load. The coupling with moving parts will be provided by a bushing-roller chain.

- To give the tape strength and increase its service life It is recommended to stitch it around the edges with fishing line using frequent stitches in increments of about 10 mm.

- It is also necessary to sew the tape along the ends to connect it into a ring required diameter, or use hinges reminiscent of a piano canopy for greater reliability.

- Make sure that additional pair of wheels, which you install on the walk-behind tractor frame, was the same diameter as the main wheels on the walk-behind tractor.

From a tire

It’s enough to simply make a durable, reliable gooseneck for a walk-behind tractor from a tire. The manufacturing process from a car tire will not take too much time, since it does not need to be stitched and lugs built up - the tire itself is a closed structure with a tread for traction.

Tires from truck or tractor wheels that have a pronounced tread pattern are best suited for caterpillar tracks.

The manufacturing process is divided into several stages:

- Using a very sharp knife dipped in a soapy solution to enhance the cutting ability on rubber, cut the gooseneck tape to the required width.

- The sidewalls of the tire are cut off with a jigsaw using a fine-tooth file.

- Hard parts on inside tires are also cut using a knife or jigsaw.

However, here there are several points that you should pay attention to:

- The tread pattern must be clearly defined, since its reliefs are a kind of lugs that increase the adhesion of the moving mechanism to the surface.

- The length of such a caterpillar is limited by the diameter of the tire, so before attaching an additional pair of wheels, you should take this into account.

From belts and chains

In order to make a tracked all-terrain vehicle from a walk-behind tractor, you can use ordinary belts with a V-shaped profile. The belts are connected to each other by lugs attached to them with rivets or screws. Thus we get a belt track.

To make a track from chains (chain tracks), you need to take two pieces of the same chain of the required length.

- The end links of both segments are unclenched in order to connect them into two closed rings.

- The loosened links are clamped again and then welded to secure the fastening.

- Sections are cut from steel of the required thickness that will serve as lugs.

- The lugs are bolted at both ends to the links of both closed chains, thus forming a raised track on the walk-behind tractor.

Homemade tracks for caterpillars

Tracks for a homemade goose can also be made independently from any suitable material. The main thing to consider is what load you are going to give to your walk-behind tractor.

From plastic pipes

You can use segments as tracks for a snowmobile gooseneck plastic pipe. For this purpose, plastic water pipe Cut No. 40 into pieces equal to the width of the caterpillar. By using circular saw saw each section lengthwise into two equal halves, or use circular saw on wood.

The resulting tracks must be attached at regular intervals to the conveyor belt with No. 6 furniture bolts with large hemispherical heads.

From wooden blocks

Sometimes, if the load on the goose is not very large, you can use birch blocks as tracks. They are not particularly durable for heavy loads, but they are lightweight, affordable, and a track with such tracks can be repaired in any convenient place.

Iron tracks

The most reliable are metal tracks made of high-quality iron. Metal pipes or profiles cut into pieces of the required length are suitable for this purpose. Profile metal pipe cut according to the same principle as plastic, and attached to the conveyor belt with bolts.

However, metal tracks, despite their noticeable strength, also have their drawbacks: they are heavy compared to plastic and wood, and can bend during use. To straighten the track, you will need to remove it from the gooseneck, and this is a labor-intensive operation.

When choosing the material from which the track tracks for your mini-all-terrain vehicle will be made, you should evaluate the degree of load and operating conditions. Light polyethylene or wooden tracks are perfect for overcoming snowy expanses, but to use a walk-behind tractor as a mini-tractor, it is still better to make a caterpillar with metal lugs.

Buy a hitch and a trailed one for a walk-behind tractor in online stores

Do-it-yourself caterpillar for a motorized towing vehicle

A motorized towing vehicle, popularly called a “motorized dog,” is ideally suited for use in northern latitudes with good snow cover. Using a walk-behind tractor, you can independently make an alternative to a dog sled, a high-speed tracked vehicle that can tow a sled with a person or a small load in the snow.

Making a caterpillar for a motorized dog with your own hands is not at all difficult.

You can use an old gooseneck from a Buran snowmobile. To increase the chassis, you should cut it in half and build it up using inserts. The tracks can be carriages from the old Buran. Three carriages with rollers are enough. They also need to be sawn and extended with inserts.

In the absence of old spare parts, a caterpillar for a motorized towing vehicle can be made from improvised materials using one of the methods described above. For example, from a conveyor belt.

For production you will need:

- conveyor belt with a width of 22 cm;

- metal bars for reinforcement;

- hardwood timber blocks for track tracks.

We bring to your attention a video showing the caterpillar manufacturing process.

Making tracks for a walk-behind tractor is a simple process, although it requires a sufficient amount of time. It is also necessary to make every effort and skill to ensure that all links of the goose are located at an equal distance from each other. This will help to avoid distortions and sliding of the caterpillar track from the load-bearing surfaces.

Real SUVs have high cross-country ability (I mean, not city SUVs). However, their cross-country ability is often limited, and it’s understandable that this is not a tank “in the flesh.” For example, on snowy slopes or swampy meadows, such a car is no longer effective. We have to resort to tractors and all-terrain vehicles on tracks, but tuning does not stand still, but develops by leaps and bounds, so in just an hour you can put your jeep, even a UAZ or NIVA, on tracks, removing the wheels, thus we increase the cross-country ability many times over...

The effectiveness of tracks has long been proven, but converting a car to such a chassis would mean a deep modernization of the suspension, which is very expensive and not always possible. Therefore, we needed tracks that would sit in the standard places of the wheels, practically on standard hubs, without deep technical changes. And you know, such options have existed for a long time! Moreover, you can remake almost any car, but of course it is more effective to remake frame jeeps or off-road vehicles with high cross-country ability, such as our NIVA.

Design principle

Nowadays they sell blocks for all four wheels of a car; we simply remove the standard wheels, screw on special adapters to the hubs and put on the tracks.

No, they are not big, but correspond exactly to the size of your car, they simply fit into standard wheel arches, there are options even for cars, although this is a little absurd.

The design is also simple, there is a triangular metal powerful frame, with five (sometimes more) pairs of rollers at the bottom and one large one at the top. On which a caterpillar made using a special technology is put on (many will say it looks like rubber), but this is not entirely true, wear resistance and elasticity are on high level, they remain soft even when sub-zero temperature. Of course, no one will tell you the composition of the material.

A standard wheel hub is installed in the upper “large” roller and placed on a rigid coupling, thus the rotating hub will transmit the rotation of the entire structure, and here you have the all-terrain vehicle ready. The big advantage is that you can turn the steering wheel like on a regular car with wheels, and when you need to, you just remove the tracks and put on regular wheels.

Track sizes

Of course, many are now interested in the sizes. So I want to quickly go over them. I personally will take the option for our cars, for example, for the NIVA, since it is in greater demand.

Width – ranges from 320 mm to 450 mm

Height – about 700 mm

Length – approximately 1000 mm.

Weight – 80 – 100 kg.

From the side it resembles a triangle, and therefore will fit into any wheel arch.

Manufacturers

To be fair, it is worth noting that they were developed in the USA, and only after that they were distributed throughout the world. Now several dozen, and maybe hundreds of companies around the world, including Russia, are doing this.

If we take imported options, then the most famous of all is the company – Mattracks, this is one of the founders of the production of such “skating rinks”. True, their prices are steep; for the price of a set you can buy a Russian car.

If you take domestic producers, then here we can highlight Chelyabinsk, it is there that rollers are produced for NIVU, UAZ, etc. The cost is several times lower than that of foreign analogues.

Main advantages

The advantages are obvious - improved cross-country ability. And also an increase. Deep snow in the fields, swamps of small swamps, and simply “well” washed out roads become easy obstacles. If we take into account what these tracks were originally developed for, it was to overcome deep snow, they were made for rescuers on mountain roads where ordinary SUVs simply cannot pass. What can I say, the caterpillars have proven themselves only from the best side.

For example, watch the video where the NIVA easily passes through deep snow and turns around “calmly”.

Changing shoes from regular wheels does not require any changes in the suspension design; you can remove the wheels with your own hands and hang the tracks in literally 1 hour. Moreover, if you need to return the wheels back, an hour and they are there. This adds a very big plus.

Minuses

Of course, there are also disadvantages, where would we be without them. The first, but obviously one of the most important, is the use on asphalt roads - here you need to maintain a special speed limit, almost all manufacturers recommend moving at a speed of no more than 40 km/h, otherwise the caterpillar itself will wear out very quickly, you will simply throw it away.

The second is that it is difficult, and I would even say impossible, for such “skating rinks” to overcome a fallen tree, not even significant at 10–15 cm in height; ordinary SUV wheels would simply run over it, but the tracks would not.

Third, this is a fairly high price, although I will dwell on this in more detail.

Price

Needless to say, this is very expensive pleasure. Taking it for fun and “rides” across snowy fields is not entirely rational.

Foreign analogues cost from $3,500 to $10,500. What is now at the exchange rate is approximately from 230 to 700,000 rubles!

Domestic producers keep amounts from 100 to 250,000 rubles.

Prices depend on your vehicle (the larger, the more expensive), load, track width, etc.

Can I do it myself?

YES of course you can, why not! After all, they are also produced by people. However, you will need to do technical research, calculate the load, and weld the triangle. Look for rollers and the canvas itself (many people also make old rubber). As you can see, not everything is so simple - although it should be noted that it is feasible.

Many people involved in making homemade equipment, all-terrain vehicles on caterpillar tracks and homemade ones are also being developed caterpillars on walk-behind tractor. When bringing this idea to life, people use the most different solutions. But making caterpillars remains big problem for lovers of this type of transport. After all, if an all-terrain vehicle or snowmobile is made with your own hands, then the tracks should be homemade.

Homemade tracks from tires

It is very common among DIYers to make tracks using car tires. For this purpose, tires with a suitable tread pattern are selected from trucks.

To make such a caterpillar, you need to cut out the sides from the tire and leave the treadmill. This is quite a labor-intensive job that requires a lot of patience, because the tool used is a sharpened shoe knife.

To make the work easier, from time to time the knife blade can be moistened in a soap solution to cut the rubber faster. One option is to use homemade device for cutting, or use a jigsaw with a fine-tooth file.

After cutting off the sides, if the track is too hard, you can remove the extra layers of rubber inside the resulting ring. If the tread pattern is not suitable for the conditions of use, then a new lug structure is cut.

Undoubted advantage homemade caterpillar from a tire in front of a caterpillar from a transport belt, in an initially closed loop, and therefore reliability. The disadvantage of this caterpillar is the limited width of the workpiece, which can be corrected by using a double-width option.

Homemade caterpillar for motorized towing vehicle

DIY caterpillar from tape

Continuation of assembling caterpillars from tape

Many residents of northern latitudes and places with poor traffic are engaged in the development and assembly of various equipment with increased cross-country ability. Tracked all-terrain vehicles are no exception. Exists a large number of various options creating such technology. But the most problematic issue for all-terrain vehicle designers is the manufacture of tracks.

You can, of course, use factory-made ones, but having completely assembled an all-terrain vehicle with your own hands, you want to have tracks too own production. Today, there are several options for creating such propulsors, which practically do not differ in their technical characteristics from factory ones.

A simple version of caterpillars

The simplest option for snowmobiles is made from a conventional roller-bushing chain and conveyor belt. Moreover, its production does not require any special equipment and tools. In this case, the work can be done almost in the middle of the living room.

For the conveyor belt to last long time, you need to trim its edges with fishing line with a distance between stitches of about one centimeter. This activity is very similar to seamstress stitching fabric. In any case, such firmware will prevent the tape from unraveling while driving. You can fasten the ends together using any in a suitable way. A swivel joint similar to a piano hinge might work for this, or just sew it together, but it's unlikely to last long.

The thickness of the conveyor belt depends on the power of the power unit. If the all-terrain vehicle has an engine from a Soviet-made motorcycle, then a tape 0.8 - 1 cm thick, used on conveyors in agriculture. To give the track rigidity, it is necessary to attach a bushing-roller chain to its inner part. This can be done using bolts or rigid steel wire. The main thing is that the chain fits snugly into the surface of the conveyor belt.

Caterpillars made in this way are distinguished by their long-term operation, although they are easy to manufacture. In addition, if necessary, you can easily carry out repairs, even in the field.

Tire propellers

Many owners of snowmobiles use regular car tires as tracks for their equipment. For these purposes, you need truck tires, and you should choose them with the required pattern so as not to complicate your work in the future.

Many owners of snowmobiles use regular car tires as tracks for their equipment. For these purposes, you need truck tires, and you should choose them with the required pattern so as not to complicate your work in the future.

To make a caterpillar mover from a tire, you need to cut off the sides, leaving only the part with the tread. This activity takes a lot of effort and requires patience, since the work requires only a well-sharpened shoe knife.

In order to make manufacturing a little easier, you need to periodically wet the knife with soapy water, which will make the process of cutting rubber easier. Some use specially designed devices for these purposes. Can also be used electric jigsaw, with a fine-tooth file attached to it. It also needs to be watered with soapy water.

The first step is to cut off the beads from the tire. Next, if necessary, you need to remove several inner layers in the resulting track. This is done to give it softness. If the tread pattern is not satisfactory, then you should start cutting a new one, which is quite a painstaking task.

This type of track lugs has one undeniable advantage over the previous option. Since it is solid, without joints, its reliability is much higher. From negative points You can note the small width of the track, but to increase it you can splice two or three tires.

Belt tracks

The ease of manufacturing of such tracked propulsion systems is increasingly attracting all-terrain vehicle owners to use them on their vehicles. Belts with a wedge-shaped profile are assembled into a single structure using lugs, which are attached to the belts using rivets or screws.

The ease of manufacturing of such tracked propulsion systems is increasingly attracting all-terrain vehicle owners to use them on their vehicles. Belts with a wedge-shaped profile are assembled into a single structure using lugs, which are attached to the belts using rivets or screws.

As a result, it turns out that the caterpillar track already has holes for the sprocket. To do this, it is necessary to lay the belts at small intervals.

Making tracks for an all-terrain vehicle

The name all-terrain vehicle refers to a vehicle with increased cross-country ability. These include tractors, snowmobiles, SUVs and tanks. Since often from improvised vehicles. Initially, this involves motorcycles or scooters, but the end result is a vehicle that is not afraid of either off-road or dirt. The increased cross-country ability of an all-terrain vehicle mainly depends on its tracked propulsion units, which are mounted on wheels.

In this version, the caterpillar will have four stripes 5 centimeters wide. They must be cut from a regular conveyor belt. Then connect the sides using a P-shaped profile. Next, you need to make balancers. Using a stamp, you need to make parts for the floor of the wheel from sheet steel. After this, it is necessary to make hubs from bronze. The half wheels should be connected with six bolts. The balancers are ready.

The next step is to produce the shafts for the track support drums. They should have holes for the bearings. Drums can be made from duralumin blanks. When connecting them together, you need to insert a rubber sprocket. It turns out that the caterpillar is driven by a drive sprocket with a chain drive. It is installed on the rear fork.

The next step is to produce the shafts for the track support drums. They should have holes for the bearings. Drums can be made from duralumin blanks. When connecting them together, you need to insert a rubber sprocket. It turns out that the caterpillar is driven by a drive sprocket with a chain drive. It is installed on the rear fork.

After which the entire caterpillar should be assembled into a single whole.

The vertical arc must be equipped with a steel bushing through which the wheel axle passes. A mechanism is attached to the eye on this bushing that secures the structure of the rear fork. Track balancers are attached to the remaining ears of the all-terrain vehicle. The mover is ready to use.

As you can see, you can make a caterpillar different ways, the main thing is to have patience and desire.