Fire hatch. Fire hatches in the attic and ceiling

Unfortunately, private houses are in the first risk group in terms of fire safety. The reason for this is the common material for construction – wood.

Protecting the lives of households in the event of a disaster is the most important task that can be accomplished design features Houses. One of them is fireproof hatches in the attic. If there is a threat of smoke or impossibility of access to rescue exits, this is The best decision V emergency situation.

Fire hatch - how to install it yourself

The simplicity of the design - a metal frame sealed around the perimeter with non-flammable material and a steel door with automatic latching - also implies ease of installation. As a rule, such access to the attic is additionally equipped with a retractable staircase.

However, considering poor compatibility wood and metal, you will have to carry out a series preparatory work, protecting the natural structure from negative influences steel, or, more precisely, the consequences of its use. So, how to install a fire hatch leading to the attic - instructions for home craftsmen:

- First you need to choose the right factory design. You need to contact specialized companies related to fire safety products.

Specialists will offer the required options. Of these, those that best suit the technical regulations are selected:

- Fire resistance limit from 30 – 60 minutes.

- Steel thickness is from 0.8 – 2 mm. The coating can be specially selected to match the interior, so as not to create dissonance. Models coated with powder paint look good, as do expensive metal doors.

- The box is equipped with a non-flammable thermosetting seal, which, when heated, expands and blocks access to smoke and flame. In quiet times, such a seal will not give drafts the slightest chance - this is especially true if attic space not heated.

- Inside the canvas there are mineral wool or fire-resistant boards. It is worth regularly monitoring the quality of the insulation - cotton mats can cake, then they need to be replaced, otherwise metal structure will become a bridge of cold.

- Closers, handles, locks and other fittings must withstand open flames and not heat up, thereby making it impossible to use. It is possible to install an anti-panic system - a wide handrail with automatic opening and closing.

- As for the issue of parameters - length-width, the fire hatch for the attic can have individual dimensions. You need to proceed from the fact that an adult can easily get into the under-roof space and what kind of staircase will be involved in this. The optimal rectangular shape is 1200 mm × 700 mm.

Separately purchased material for laying between wood and metal box. Well, the corresponding tool is a screwdriver, Circular Saw, fasteners

- Next, markings. Contours should be outlined with allowances of 5-6 cm more exact dimensions. Such gaps will serve as compensation for the continuous shrinkage of the house, which can jam even metal and at the same time crack under its resistance.

It is enough to drive in four nails or fix the screws in such a way that the tip comes out on the other side. There is no need to outline contours on two surfaces at once and then adjust what is needed - then curvature cannot be avoided.

- Then, the freed wood is removed and the resulting hole is put in order. What does it mean?

Like cutting window opening, and the hatch, square or rectangle is processed protective compounds for damage, grooves are selected on opposite sides and sealed with jute. The bare wood is previously covered with a vapor barrier.

- Now they are constructing the box - the fire hatches to the attic are first disassembled into their component parts. A beam with a cross section of 50 mm is installed in the selected groove. You can add a few small blocks under short slats– the resulting expansion gaps must be foamed with a mounting substance.

Then the long parts of the box are attached, followed by the short ones. You should not screw the box tightly - shrinkage will go more smoothly if there are no obstacles to it.

- Next, install the hinges and screw the door, having previously attached fittings to it - a handle or an anti-panic system. All that remains is to foam the expansion gaps and carefully cut off the sloppy protrusions. After this, decorative trims are fixed.

The entire structure is checked by repeated opening and closing, all interfaces and mechanical parts are immediately lubricated. To do this, use silicone grease - it will prevent moisture from penetrating into the moving parts in case of condensation. The material needs to be constantly updated.

The hatch is ready. However, to reach the attic space you will need a ladder. It can be folded, placed on the hatch door, so that in case of danger it can be quickly brought into working condition.

But not to shy away from design and interior wooden house You can make a twisted or straight design. How – more on that below.

Making a simple wooden staircase leading to the attic

Will be needed following materials and tools:

- Support beam 150 mm wide and up to 5 cm thick – 2 pcs.

- The steps are 2.5 cm thick, the number depends on the height of the ceilings and the roll of 45⁰.

- Fasteners - self-tapping screws, anchors.

- Varnishes or other glazing compounds.

The appearance of such a structure will be determined by the steps, so you need to work hard on creating them. They can be asymmetrical protrusions, oval or pedal-shaped.

They are pre-drilled in the right places for fastening, processed and varnished, but they cannot be made slippery. There are special overlays that are glued to the surface of the wood and thereby prevent misfortune. Branded models are equipped with special notches.

The fastening of steps has its own rules - the distance from one to another does not exceed 19 cm. Each step should be fixed in two places to prevent unnecessary load on the area.

For work and beauty appearance use anchors made of yellow metal - a shade similar or close to wood. Install the steps strictly parallel to the floor.

The supports should be installed so that in the event of an emergency, they will not budge even under a load of 150 kg - the optimal weight that a home-made ladder must bear. The ends should not rest directly on the fire hatch of the attic exit - they should be secured to the ceiling. They, like all wood, must be processed and, in order not to deviate from the intended interior, varnished.

Railings or other guardrails on the attic stairs leading up to the fire hatch into the attic should not be pretentious or too bulky. They are created only for the convenience of use by elderly people or children. In case of an emergency, they will speed up the ascent process. The railing supports are fastened frequently - every two pairs of steps.

The rescue of drowning people is the work of the drowning people themselves. This catchphrase fully refers to ensuring own safety. The main threat wooden house is still fire.

After a fire breaks out in one place of the building, as practice shows, the fire begins to spread to other nearby rooms, moving to the upper floors and roof. Among the main ways for the expansion of a fire, in addition to the penetration of flame and combustion products through window and door openings, it should be noted such factors that contribute to the spread of fire, such as hatches leading to the attic or roof, insufficiently securely closed elevator shafts and channels in the walls laid in them with cables. To securely close these openings and provide protection from high temperatures open flame install a fire-resistant product such as a fire hatch.

Such a fire hatch leading to the attic is capable of quite long time prevent fire from entering rafter system or roofing material. It should be noted that a properly closed fire hatch is an almost completely airtight barrier. This prevents smoke from entering carbon monoxide and other combustion products into other adjacent rooms through a ventilation or cable duct, attic floor or elevator shaft.

Design and features of the fire hatch

The most common fire hatch for roof access has a fire resistance level of EI 60, which indicates that this design In case of fire, it will be able to withstand the effects of open flame for at least 60 minutes. In this case, the temperature of the hatch on the side opposite to the fire will not exceed +100 ˚С.

Structurally, such a hatch consists of two metal components with the same fire-resistant properties: the box (frame) and the hatch panel. As a rule, they are made from bent metal sheets with a thickness of at least 1.5-2.0 mm. The empty cavities of the hatch and frame doors are filled with non-combustible basalt (mineral) slabs. To increase the level of fire resistance, they are also impregnated with a special solution. Fire hatches must be equipped with hinges, door fittings and locks that remain operational at high temperatures.

Our offer

NPO Pulse offers consumers from Moscow and Moscow region to buy at favorable price wholesale and retail fireproof technical hatches. Products are supplied from the manufacturer, which explains relatively low prices at her.

The attic is not the most visited room in the house, but easy access to it does not hurt

The attic of a residential building is often used as storage for old or seasonal items. In order to easily access the attic, you need to carefully consider the lifting options and choose the most suitable one for your home. The hatch to the attic will become great solution for unimpeded entry into the storage facility.

The most common are the following two methods of installing an attic hatch.

The first method of arrangement is pediment. It is necessary to make an opening on the gable for the attic door. An attached or stationary ladder is connected to the hatch from below. Dignity this method is that no holes are made in the ceiling.

Pediment entry to the attic

The second method is the simplest and cheapest - creating an opening directly in the ceiling.

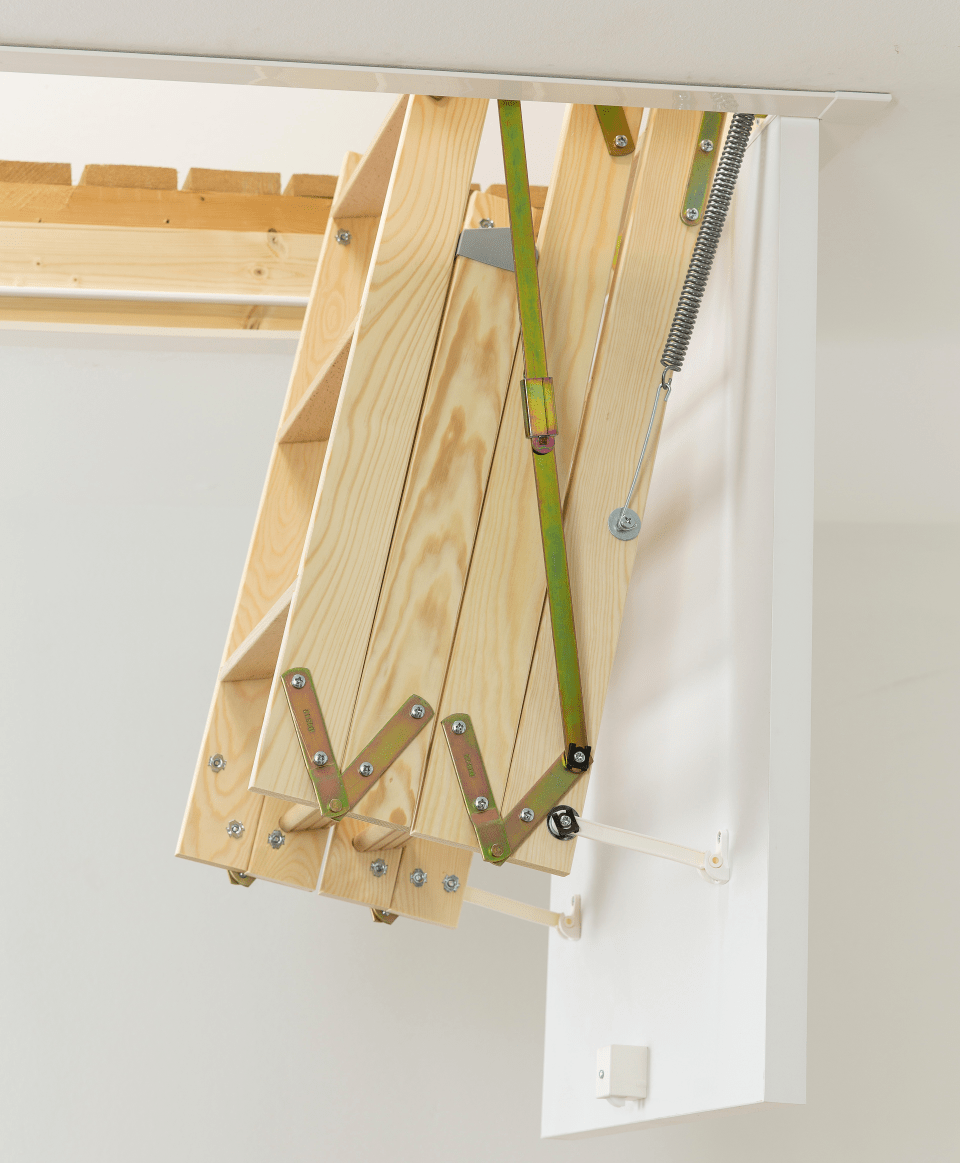

Attic hatch built into the ceiling with folding ladder

Hatch design options and purpose

An attic hatch is a door panel that opens and closes and is built into the ceiling to provide access to attic storage. In addition to equipping the attic with a hatch, it is necessary to consider the type of staircase structure. Attic stairs presented various types attached and folding variations. Folding ladders mounted in the hatch door are very ergonomic to use.

Hatch and ladder variations:

- The most common solution for attic access is an opening hatch door with hinges. It is equipped with a latch, which opens after the built-in ladder is completely unfolded. You can also open the latch using a cord while standing on the floor. These models are easy to insulate.

- Sliding attic hatch - the cover moves to the side, freeing up the passage. This design complicates the insulation procedure, but makes opening easier. This hatch model is equipped with an electric drive so that you do not have to move it manually.

- The hatch cover is equipped with a locking mechanism. From the simplest - a latch, to the more complex - a thin cable with which you can open the latch while standing on the floor.

Wooden four-section beech staircase with hatch to the attic

The manhole cover is easy to install yourself. Plywood, OSB sheets, and MDF are suitable for it. You can also install a metal or wooden structure. All these materials are quite affordable.

Features and types of hatches

Depending on the location, the attic hatch is:

- horizontal;

- vertical;

- corner.

Horizontal arrangement - the location of the attic opening in the ceiling. These are the most common and simple designs. They are distinguished by ease of use and ease of manufacture and installation.Vertical structures are a kind of attic crawl space.Corner structures are mounted mainly in attic rooms under a sloping roof.

The main materials for door production are: wood, metal, plastic.

Horizontal arrangement of the attic hatch

Hatch characteristics:

- easy installation;

- ergonomics;

- universal design in harmony with the surroundings;

- thermal insulation layer.

Manufacture and installation of a hatch

The hatch to the attic in interfloor reinforced concrete floors must be installed at the junction. This technique will evenly distribute the load between the two slabs and eliminate the possibility of weakening and sagging of the structure.

Important!

When cutting out an opening, you must use a grinder equipped with a metal disc, a hammer drill, or a crowbar with a sledgehammer.

Attic opening in concrete ceiling

To arrange access to the attic of a house with insulation, you must comply with the following: step-by-step recommendations:

- Carefully measure the dimensions of the opening, draw a drawing, taking into account the shape and detail of the structure.

- Build a frame from boards 200mm thick. The predominant shape is rectangular.

- The attic hatch is usually produced in standard sizes: 600*1200mm. But they may well be individual. The size of the opening depends on the type of purpose and use of the attic.

- Prepare an opening on the ceiling according to the drawings and verified dimensions. It is also necessary to take into account that the hole in the ceiling is cut 50mm larger than the size of the hatch. The lining of the opening must be additionally reinforced with a frame.

Advice!

If the ceiling is lined with wood, then in order to save money, the hatch cover can be made from the remnants of the material that was used for the ceiling. In other cases, the material will have to be purchased additionally.

- Strengthen the hinges to the hatch and to the opening.

- Install a diagonal spacer on the cover using self-tapping screws and an angle to give it additional rigidity and strength.

- Standard is used as a heat insulator. thermal insulation material. Will do mineral wool, polystyrene foam or polystyrene foam.

- To avoid moisture collection, it is necessary to equip the bottom with a vapor barrier.

- Install the fittings: door closer, latch and handle.

- Cover the frame with platband.

- If necessary, install a ladder.

Insulating the attic hatch with foam plastic

Installation of a finished hatch structure with a built-in ladder

Ready-made attic exits are distinguished by their variety in type and materials of manufacture. A metal hatch to the attic is slightly more expensive than a wooden one.

Before purchasing a product, it is necessary to determine the location of the hatch and take careful measurements. Very often, ready-made hatches are already equipped with folding metal ladders.

Advantages finished products:

- compactness;

- multifunctional design;

- universal design;

- easy installation.

After purchase, you should make an opening in the ceiling in accordance with the dimensions indicated in technical specifications products.

Metal hatch to the attic with built-in stairs

Installation sequence:

- Raise the product to the attic floor.

- Install 2 safety boards from below and support the structure on them.

- Install the product using spacers and a hydraulic level.

- Secure the front and rear frames with screws.

- Polyurethane foam fill the voids.

- Remove the auxiliary mounting boards.

- Check the stability of the structure by disassembling and reassembling the ladder and loosening the bolts.

- If necessary, straighten the structure and tighten the bolts.

Ready-made hatches are easy to install and fit almost any interior design.

Today you can buy an attic ladder with a hatch from the world's best manufacturers

The advantage of ready-made sliding stairs for attic openings is:

- compactness;

- versatility in use;

- ease of installation;

- design.

When using sliding attic stairs no extra effort required. This is why purchased products are common and more reliable than homemade designs. Two people are enough to install the attic exit. One performs work directly in the attic and lifts the structure upstairs.

Installation of an attic ladder with a hatch

Fire exit to the attic

The fire-resistant hatch is designed for timely evacuation of residents from the house during a fire. A fire exit is installed if the building is located in a fire hazardous area.

The fire hatch must comply with technological standards and markings.

Important!

Before purchasing, you must carefully read the technical documentation of the product. Study information about the tests carried out and the fire resistance of the material, which must be at least 6 minutes.

Metal is the most practical fire exit. It is equipped with heat insulators and seals, which prevents evaporation during fires.

Fireproof attic hatch with drop-down ladder

Schematically, a fire hatch consists of a frame of two profiles that simultaneously form a platband. The frame is made of steel. The internal cavities are filled with fire-resistant heat-insulating agents.

The vertical stand is equipped with a latch, which is fixed to the ceiling and fastens it to the hatch door.Thermal sealing tape is laid around the perimeter. During a fire, it expands and fills the gaps between the box and the canvas.

Hatch surface options:

- Tin plates.

- Treatment chemical composition, which does not respond to elevated temperatures.

- Glazed.

- Single leaf.

- Bivalve.

The standard fire resistance requirement for a door is 30 minutes. A single-leaf exit with these characteristics is available.The double-leaf exit is equipped with closers, making it easier to open and close the doors. Such hatches can withstand temperature attack for an hour.

Ceiling fire hatch in the attic

The horizontal fire exit from the house must meet additional requirements:

- the door opens upward;

- the hinges and frame are additionally strengthened;

- minimum size of installation gaps;

- equipping the hatch with a folding compact heat-resistant ladder.

Important!

The ladder must withstand a load of 250 kg.

The attic exit also serves as a protective structure equipped with latches. This is a durable, reliable device.If necessary, the latch can be easily unlocked from the inside.The exit door is also equipped with a fireproof lock, which has the ability to self-lock, so in the event of a fire the room is hermetically sealed.

In relation to the roof, the attic exit must be located taking into account the required space.Based on the regulations and requirements, the dimensions of the hatch must be at least 200*200mm and no more than 1500*1500mm. It is best to use average values. They are the most compact and allow you to move around.The frame should be positioned strictly at an angle of 90 degrees. Door thickness – 1mm. Door height – 1200mm, width – 1000mm. These are the most common average values.

Fire hatch for access to the roof

Fire hatches are sold in specialized stores, or are produced to order from manufacturers.The choice of fire exits must be taken very responsibly, having first studied the rules and requirements for a certain type of room.To avoid unpredictable situations, you need to take your choice seriously and purchase a quality product.

Manufacturing an emergency, insulated hatch to the attic

Fire hatches - fire-resistant protection of critical communications and equipment

To ensure the safety of those located in wall openings technical devices and cables are designed fire hatches. Modul-K LLC is engaged in the production of highly reliable products of this type individually for each facility. The passport, certificates of conformity and marking plate with the main characteristics confirm the performance.

Fire-resistant hatches are an indispensable product for important and critical facilities

By preventing the spread of fire and combustion products, such products are necessary, first of all, at those facilities where fire safety requirements are particularly high. high requirements. These include ventilation chambers, elevator shafts, rooms with electrical panels, emergency exits, etc. Fire-fighting structures produced by Modul-K have a number of serious advantages.

- Protection of openings from combustion products and fire.

- Compliance of fire hatch production regulatory requirements standards, which is confirmed by documents.

- The body can be painted in any color from the RAL catalog - the choice is made by the customer.

- Variable design of fire-resistant hatch with opening to the right or left side- regardless of this, exemplary fire-fighting properties are guaranteed.

- Qualified installation teams with a license and all necessary permits for this type of work.

- Delivery and installation in the shortest possible time.

These types of structures are most often made without trim, but with a threshold. You can submit an online application for the purchase of a fire-resistant hatch right now. Prices for these products are indicated in the proposed catalogue.

Fire safety certificate SSPB.RU.OP031.V.00415.

Standard equipment for fire hatches:

- folded sheet, sheet thickness 1 mm;

- thermal insulation - hydrophobized energy plate;

- end box;

- cylinder mortise lock - monoblock “NEMEF”;

- black push-action handles “NEMEF”;

- cold smoke seal;

- thermoactive seal;

- coating - epoxy-polyester powder paint- RAL-7035 (light grey).

Additional equipment for fire hatches:

- corner box;

- closer;

- lock with anti-panic function;

- coating color at the customer's request (according to the RAL catalogue);

- anchor bolts and plugs for mounting holes.

Product design diagrams

Fire hatches in standard sizes:

|

Product names |

Standard sizes about the box, mm |

|

Fire hatches EI 60 |

|

It is based on a metal frame, which is made of high-quality steel sheet 2 mm thick, which is bent into a complex profile.

From the inside, the profile cavity is filled with a special insulating material.

Using reliable hinges, the canvas, which is equipped with a lock, is hung on the frame. A special thermal sealing tape is attached around the perimeter of the box for sealing.

An important part is the cold smoke seal, which is placed in the groove of the profile.

The surface is treated with a primer or powder coated. The customer selects the optimal coating color from the RAL catalog.

How to order fire hatches

The products are presented in several versions. Whatever product you choose, its quality is confirmed by certificates and documents with test data.

The company "Steel Group" has a license to install fire protection structures. By entrusting the installation to the company’s experienced specialists, the client can be confident that the installation will be carried out professionally.

All metal structures can be ordered on the company’s website. Delivery and installation of the hatch will be scheduled at a time convenient for the buyer.

Most popular sizes:

- 900x900

- 800x800

- 700x700

- 600x800

Product Description

- Among our products we offer fire-resistant hatches various options execution. It is advisable to install them in rooms with increased safety requirements, where the possibility of spontaneous combustion is highest. They are installed in ventilation chambers, elevator shafts, electrical switchboard rooms, and in exits that lead to the attic or, conversely, to the basement, to various niches, channels, other communication points where their presence is necessary, and to warehouses of combustible materials.

- All models comply with modern standards and provisions of SNiP 21-01-97. Fire resistance EI 60.

- The kit necessarily contains documents that contain test data and their results regarding maximum resistance to heat. In addition, each model is marked for inspection. All products have quality certificates. In addition, we are licensed to install. By contacting us, you receive high-quality equipment that guarantees your safety, and professional installation services.

- LPM-1 are intended for filling openings in walls, partitions, on evacuation routes, as well as in industrial, public, residential buildings and structures where there is a need to protect the facility from the spread of fire.