DIY refrigerator incubators. How to make an incubator from an old refrigerator

Today there are many people who make money from raising and breeding birds. In order to save money, people are increasingly making many necessary equipment yourself, if this is possible, of course. For example, poultry farmers often create incubators at home from various objects, often used old refrigerator.

How to properly make a home incubator. Basic moments

- Eggs need to be stored for less than ten days before incubation. At this time, they should lie alone at a certain distance, approximately a couple of centimeters. It is also necessary to maintain the required temperature within thirty-eight degrees Celsius.

- It is necessary to maintain the humidity in the room at around fifty percent until hatching. Afterwards it is necessary to maintain eighty percent, and lower before choosing chickens.

- It is also necessary to position the eggs correctly; the tilt level of the tray should be forty-five degrees.

- If the eggs are ducks, then the angle is ninety degrees.

- When placing eggs horizontally, remember to move them every sixty minutes. A few days before the birds appear, it is not recommended to touch the eggs.

- It is advisable to adjust humidity and temperature forced ventilation at a speed of no more than six meters per second.

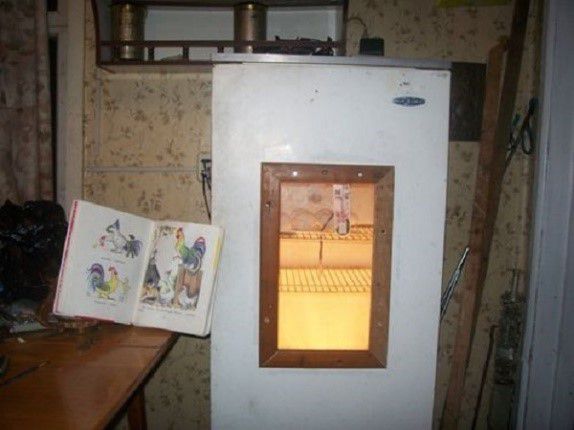

We make a vertical incubator from an old refrigerator. Scheme and drawing

To build an incubator at home, you need to take and remove all the contents of the refrigerator and prepare a place for future shelves. Also, do not forget to prepare space for various additional components, relays, thermometer, and so on.

After the structure is assembled, you need to connect to the power supply and set the required temperature.

Next, following the figure, you can understand in detail the principle of operation of the incubator. Also find out about the timing of the decrease or increase in temperature during the incubation period.

Do-it-yourself vertical incubator from a refrigerator

Do-it-yourself vertical incubator from a refrigerator Upper frame

You can easily use a TV box as a frame, you just need to make it more rigid with the help of slats and fittings. In order to maintain a certain temperature, use porcelain sockets with lamps; their power should not be high. Three lamps are intended for heating, one for humidification.

It is necessary to place the eggs from the lamps at a distance of nineteen centimeters, about fifteen centimeters under the grate. The front of the incubator must be removable, otherwise you will not be able to change water, change trays, turn eggs, etc.

This version of the incubator is quite economical, and it will not be difficult to create it yourself a lot of work.

In addition to the old refrigerator, you can use the most different materials, to do this you just need to go to the Internet, where there is a lot of different information on this topic.

Video on the topic :

Poultry farmers involved in breeding chickens or other productive breeds of birds sooner or later decide to purchase an incubator. However, when they go to the store, they do not expect to see sometimes extremely high prices for different options for such a desired device. How to leave money in your wallet and at the same time become the owner of a capacious device for hatching chicks without the participation of a chicken? It’s very simple: make an incubator out of a refrigerator with your own hands!

Many of us have old summer cottages old, Soviet refrigerators are stored, working ones, however, cannot be compared with modern models. It's time to get rid of junk and turn it into agricultural usefulness!

The installation will be located on the back wall, with the door facing the ceiling, so immediately remove shelves and other interfering elements from inside the refrigerator.

"Lying" incubator from an old refrigerator

Advantages

Let us list the main list of advantages that incubators independently created from refrigeration units have.

Necessary materials

So, in order to independently assemble an incubation device from an old refrigerator, we will need the following materials:

Let's get started

Step 1

We lay the old refrigerator in a horizontal position and remove everything unnecessary from the inside. Then, using cleaning agents and disinfection liquids, we treat the body from the inside, and at the same time from the outside, to prevent the development of pathogenic bacteria near future chicks.

Step 2

We cut a hole in the door of the unit through which the thermoregulation device of your choice with a sensor will fit. Then, carefully insert the device into the hole and secure it with the outer and inside duct tape.

Step 3

We take a prepared sheet of plywood and install 4 cartridges on it, to which we reach electric wires, and then screw in all four 100-watt lamps. Then we install the assembled heating and lighting device on the inside of the refrigerator door, securely fastening the plywood panel to the body of the future incubator.

Step 4

Let's prepare the air humidification system. It will consist of plastic pallet, which we will set to back wall refrigerator (which is now the bottom of the incubator). Pour inside the container clean water and install it inside.

Step 4

A bit higher installed pallet install a metal grid on which to place plastic egg boxes. This is necessary so that the eggs are at some distance from the water and do not become waterlogged.

Making a vertical incubator from a refrigerator

The unit obtained as a result of following this instruction is obtained standing vertically. This design is more convenient than the horizontal one, as it leaves the opportunity to create a window for observing the hatching birds.

Materials needed

Let's start listing the materials and tools that will be useful to us in the process of transforming the refrigeration unit into an incubation unit:

Let's get started

Step 1

We remove everything unnecessary from inside the future incubator:

- cells;

- shelves;

- side niches;

- boxes, etc.

The first stage is removing unnecessary parts from the refrigerator

After everything has been removed unnecessary details refrigerator, we begin to clean the body inside and outside. As mentioned above, first we wash the body with detergents, then using antiseptics. Having washed and treated each crack, we move on to the second stage.

Step 2

Let's begin to repair the internal and external damage to the body of the old refrigeration unit. To do this, we carefully examine the surfaces of the walls and seal each hole found with a piece of fiberboard, carefully gluing it over the damage.

Step 3

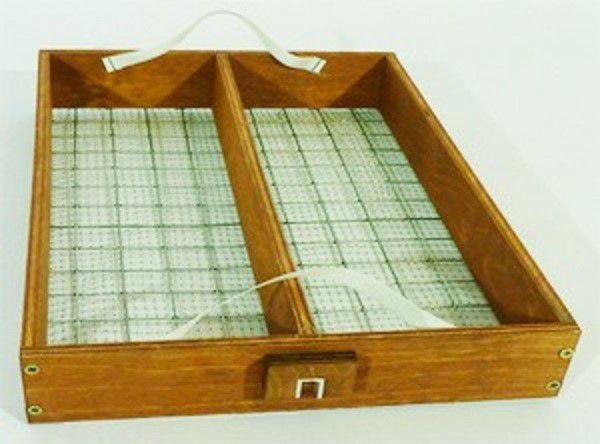

We make trays. Calculate the approximate number of eggs planned to be placed inside the future incubator. Based on the obtained figure, we will proceed to purchase or manufacture of boxes. Read further in the article about how to make boxes.

Step 4

We will install ventilation. In order for air to circulate constantly throughout the incubator, it is necessary to mount a fan on the back wall of the refrigerator, and the motor part is installed outside. Along the perimeter of the front door of the refrigerator, it is necessary to make several holes through which air will penetrate into the unit.

Step 5

Heating queue. Carefully place a tubular heating element around the fan blades on the back wall of the refrigerator. This position is next to ventilation system will distribute heat evenly in the incubator, covering even distant corners.

Step 6

Place a container of water on the bottom of the refrigerator. Since the humidity level must be maintained stable over a long period of time, it is better to use a deeper device as a tray, approximately like a cat tray.

The disadvantage of this type of incubator is exactly the same as the previous one: the lack of automatic egg turning. This will again have to be done manually, carefully stirring the houses of the unhatched chicks. It is best to work with gloves.

Vertical refrigerator incubator with semi-automatic egg turning

This type of incubator from a refrigeration unit is more difficult to implement than the previous ones, however, with its help you can significantly reduce the time spent on turning eggs yourself. No, the incubator will not do it on its own, however, from now on it will be possible to turn the cells over in one motion.

The manufacturing principle is similar to the previously described method, however, there are significant differences in the installation of additional mechanisms. You will have to spend a little more time, but the result will make you experience real pleasure.

Materials and tools

Video - Do-it-yourself heating element for an incubator

Let's start construction

Step 1

We cut off the section inside that separates the freezer and refrigerator compartments, if there is one in the design. We remove all excess from the inside and seal the cracks, by analogy with the instructions for the second and first methods.

Step 2

We treat the body of the future semi-automatic incubator with cleaning agents and antiseptics, wipe it dry and prepare it for installation of the main parts.

Step 3

We find the center of the front door and rear wall of the refrigeration unit and at this level we install racks, which we fix in the device body using metal screws. We make holes in the racks at the level of the shelves.

Step 4

In each cellular egg tray we insert a metal axis, the diameter of which will be approximately 8-9 millimeters. We install both ends into the racks, getting even rows of boxes between them.

Step 5

We attach a metal strip to the egg boxes using screws as fasteners. The gap should be at least two millimeters. From the bottom side of the bar you need to hang a five-hundred-gram weight, which can be played by absolutely anyone. heavy object. A pin is attached to the free part of the bar from below, which plays the role of a fuse, preventing it from going inside due to the pressure of the suspended load.

At the top of the incubator, a bar extends to the outside of the housing. To do this, you need to drill a slot in the top of the refrigerator.

Step 6

We install the breathing tubes into the side of the refrigerator by drilling corresponding holes in the body, top and bottom, each time at approximately a third of the height.

Step 7

We will equip the lighting and heat by installing three lamps with a power of approximately 100 watts on the back panel of the refrigerator. According to the diagram, we connect a thermoregulatory device to them.

Step 8

Ventilation in the form of a part from a computer or small household fan it is installed so that air must pass through the heating elements.

Step 9

Fill the pan with water and place it on the bottom of the incubator.

That's it, the semi-automatic incubator is ready! To turn the eggs, you just need to lift the bar up and then release it, securing it with a pin in another hole. During this procedure, the trays attached to it tilt in the other direction, changing the position of the embryo inside the egg, and also exposing the other side to heat. This way you will save a lot of time on manually transferring eggs and get high-quality and healthy feathered offspring.

However, we all understand that a semi-automatic incubator is not yet ideal. Therefore, we advise you not to make a decision before reading the following instructions, with which you can make a fully automatic incubator!

Making an incubator from a refrigerator with an automatic egg turning device

Study this carefully original way making an incubator from an old refrigerator that will turn the eggs inside itself automatically. Then you will have to take only minimal participation in the artificial incubation of eggs, which consists of:

Necessary materials and tools

So, to make this miracle unit we will need:

We are building a unit

Step 1

We wash the refrigerator and remove everything unnecessary from it. Because in this variety homemade incubator the heating elements will be at the level of the freezer, cut out four holes in the plastic segment separating it from the main refrigeration unit, equal in diameter to small fans, remove all shelves, cells, grates and other components for the refrigerator.

Step 2

We make a window in the front of the refrigerator from the bottom. It can be any size you want. Cut it out required size hole in the refrigerator and treat the cut areas.

Step 3

Install a frame made of aluminum or wood into the cut hole; it is better to give preference to the first material, as it is more durable. At the same time, install the glass or plastic plate inside the frame. Seal the joint gaps with sealant to prevent cold air from passing through the gaps into the incubator. The window is ready. Now you can observe what happens to the eggs during the incubation process without opening the refrigerator door and without disturbing the microclimate.

Step 4

Insulate the front surface of the refrigerator with heat-reflecting material, especially around homemade window. Foil insulation will do. This is necessary so that the heat produced by the lamps does not pass through the thin parts of the housing to the outside, but is reflected inward.

Step 5

Making crafts metal carcass to install grates on which we will later place trays with eggs. To do this, we weld thin profile pipes and screw them to the bottom of the refrigerator. We fix metal gratings one above the other.

Step 6

We make the mechanism responsible for turning over. The role of the motor drive is played by parts from a regular bicycle - the chain sprocket. They are attached to a metal sheet welded to the side profile frame devices. The driven drive sprocket is welded on the outside of the sheet, the drive sprocket is mounted on a pin.

The elements supplying electricity to the system will be Limit switches. Once the device reaches its extreme position, power will stop flowing and the system will stop operating.

The motor is driven by a pair of timers set so that operation resumes every 6 hours.

Step 7

The thermostat is installed at the level of one third of the entire height of the refrigerator. It is mounted and secured in the housing. Heating elements in the form of lamps are installed in the place of the former freezer. Switching the heating on and off is done using the regulator on the relay.

Step 8

We set up ventilation in the following way. Into the holes we cut in advance in the plastic segment separating freezer from the refrigeration room, install fans connected to electricity and secure them to the surface with metal adhesive tape.

So, our automatic incubator is ready! Now you can relax and truly enjoy the process of raising birds!

How to make an egg cell yourself

The easiest way is to buy plastic mesh trays, since they are designed for an incubator and you won’t have to waste time making them.

However, if you decide to make them yourself, you will need the following materials:

- metal mesh;

- wooden blocks, 4 pieces;

- two wooden corners;

- nails.

The size of the mesh fabric depends on the size of the refrigeration device you have chosen as the basis for the future incubator. However, there are recommendations regarding the size of the metal mesh cells, depending on what type of bird is hatched inside the device. We invite you to familiarize yourself with them in the table below.

As you can see, the size of the cell changes depending on the size of the future egg that is installed inside.

Let's get started self-production cells

We present a table of the pros and cons of making cells yourself:

As you can see, it is better to give preference to a purchased plastic box. However, if you are still committed to completely making your own incubator, replace everything wooden elements in the design of a homemade cell on metal rods or tubes, and nails on welding machine to level out as much as possible Negative consequences humidity inside the incubator and extend the service life of the manufactured part.

Windows for incubators

You can make a window in the body of an incubator made from an unnecessary refrigerator using each of the methods described in this article. Only the location of cutting the opening for the frame and glass, as well as the materials used, will differ.

Let's list the most popular materials, which are suitable for making window frame in the refrigerator body:

- aluminum;

- tree.

It is easy to understand why these two names are preferred. Everything is simple and easy to work with. However, aluminum is much easier to clean and treat with antiseptics than wood, so give preference to it.

You can also look at how eggs develop through two materials:

- plastic;

- glass.

These options are equally suitable for installation in an incubator from a refrigerator, but still, glass has a special advantage - strength. Since the assembled unit will be in use for years, make an investment in the future and install a glass window.

Electrical wiring

There is no need to additionally insulate the wiring inside the incubator, since in most designs they do not interact directly with newborn chicks or other possible dangers. However, if you are concerned, you can run the wires inside the sections of the usual rubber hose. There is a high degree of practicality in such protection: the likelihood of accidental damage to the wires by an awkward movement of the hand or as a result of another incident is reduced.

Where to get parts

Most farmers have one similar trait - a refusal to accumulate unnecessary trash. Of course, everything will be useful in the household, but only a sloppy person will conduct business in a mess. Therefore, you may not have either an old refrigerator or metal gratings. Don't think that buying everything necessary materials will cost a pretty penny. On the contrary, many people dream of putting away the junk they have accumulated over the years and getting at least a minimal profit for it.

Automatic incubator kits

For those who do not consider themselves a technical genius and cannot repeat the installation automatic system even according to the attached diagram, we have an interesting hint. Many agricultural stores sell automatic incubator kits that contain the following required items.

Depending on the cost of the set, it is supplemented with a ventilation system, additional trays, etc. The kit often includes additional devices that are useful to poultry farmers, for example, an ovoscope, which is used to check whether the fetus continues to develop inside the egg.

Let's sum it up

So, now you know how to independently assemble the following types of incubators based on an old refrigerator:

- ordinary, requiring human participation;

- semi-automatic, with the help of which turning is carried out in one movement;

- automatic incubator that requires only periodic addition of water.

Of course, to recreate each of the described units requires a certain skill, construction knowledge and experience. The work is not hard, but painstaking and meticulous, requiring perseverance and perseverance of the master. It is possible that during the installation process some parts and mechanisms will have to be redone.

An important point is the quality of the selected parts. Despite the fact that you will find many of them in the “throwaway” stash, keep an eye on the strength of the materials. You cannot use completely worn ones, because they will be of no use. A breakdown will occur after a few days of use and not only your work will be lost, but also a whole brood of feathered babies.

We believe in your success! Follow the instructions carefully, look at the diagrams presented in the article, and then you will succeed.

Video - Incubator from the refrigerator

And another poultry in personal farming - an interesting and exciting activity, and when competent organization also very profitable.

Modern breeders are constantly working to increase the productivity of chickens, creating more and more new breeds, aimed mainly at industrial breeding, as a result of which the instinct of hatching eggs in chickens has greatly weakened, and in some breeds the instinct to hatch eggs has completely disappeared. This problem is easily solved with the help of an incubator.

If you take and look at a budget, factory-made household incubator, you can be convinced that there is no space nanotechnology in it, but on the contrary, everything is quite simple, this leads to the thought: “I can do this myself.”

There are many different methods, but we will consider the most, in our opinion, convenient and economical, namely an incubator from an old refrigerator. Using a refrigerator as a future incubator, we have the advantage of a high-quality factory case with excellent thermal insulation, and this greatly simplifies the work and saves us money.

Basic incubation conditions

Before we begin to describe the design, I would like to write a couple of lines about the conditions that need to be created in the incubator:

- The number of days from booking to withdrawal should be 20–21 days.

- The distance between eggs in the incubator should be 10–20 mm.

- It is necessary to ensure a certain air temperature throughout the incubation, depending on the period.

- The eggs in the cells are placed vertically, narrow side down or laid out horizontally. Having placed the eggs vertically, it is better to install the trays at an angle of 45 degrees for ease of turning them over.

- If the eggs are positioned horizontally, they must be turned 180 degrees from their original position. In automatic mode, the eggs are turned over once an hour. Manually, at least three times a day, but preferably every 3 hours. Approximately three days before the end of incubation, stop turning the eggs.

- It is very important to create good air circulation. Circulation at a speed of 5 m/s is considered optimal.

It is important to know: You should not put eggs in the incubator that have been stored for more than seven days. The hatching rate from such eggs will be much lower.

Three different ways to assemble an incubator

Let's look at a few different options making an incubator from a refrigerator.

Horizontal method

A simple and common design that does not require special effort. The main requirement is the presence of a refrigerator with intact casing and thermal insulation.

You will need:

- refrigerator (if there is a freezer, it needs to be removed);

- 4 light bulbs of 100 W;

- thermostat;

- drill;

- trays;

- scotch;

- screwdriver.

Note: since the homemade incubator will be positioned horizontally, that is, with the door up, all shelves from the refrigerator must be removed as unnecessary.

- First of all, we make a small hole in the door (about 5x5 cm) for ventilation and to run inside the thermostat sensors, which are attached next to the hole with tape. You can purchase a ready-made thermostat, or make it yourself. He tells in detail how to make a thermostat for an incubator with your own hands.

- On the inside we attach a sheet of plywood on which we install four light bulb sockets. The same hole is cut in the plywood as in the door.

- A container of water is placed at the bottom of the incubator to humidify the air.

- Place an egg tray over the container.

Vertical method

- fridge;

- welding;

- metal wire with a diameter of 6 mm;

- fiberboard sheets;

- thermistor, thermometer;

- drill;

- glue, spatula;

- fan for additional ventilation and uniform heat distribution (if you plan to place more than 50 eggs, you will need a fan.

- You will need:

Step-by-step description of the work stages:

- First of all, we get rid of shelves and irregularities inside the refrigerator and close it using fiberboard sheet the cracks that arose from this.

- In the incubator body (top) we make two holes into which we mount a thermostat and a thermometer.

- We make a frame for the trays from a rod and tie it with a wire mesh. We secure the trays in the refrigerator body.

- We attach a fan to the back wall with heating element, which can be simple light bulbs or a tubular heater.

- A container of water is also installed at the bottom of the incubator.

The main disadvantage of this design is the lack of automation. You'll have to turn it over a large number of eggs by hand. has a more complex device than the design described above, but at the same time it turns the eggs without human intervention.

Semi-automatic method

The most complex of the presented options, however, it saves time and makes it possible to increase productivity.

You will need:

- fridge;

- self-tapping screws;

- trays;

- metal stands;

- a heating element;

- fan;

- metal axles, as many as trays;

- thermostat;

- sinker;

- strip with holes for axles;

- pin;

- water container;

- screwdriver and drill;

- breathing tubes with a diameter of 30 mm 2 pcs.

Step-by-step description of the work stages:

- We cut out the freezer section with a grinder.

- In the center of the side walls of the refrigerator, we use self-tapping screws to fasten strips with holes for the axles.

- We thread axles through the middle of the trays, which are inserted into the slats in such a way that the trays are secured between the slats.

- Another metal strip is attached to the side of the trays closer to the front of the trays, combining them into a single structure. We attach a load to the bottom of the bar, and bring the top up through drilled hole. Now by pulling this bar up or down, we turn all the trays at once. To fix the bar in the upper position, just drill a small hole in it and fix it by inserting a cotter pin into it.

- We install the breathing tubes in one of the side walls, at the top and bottom, at a height of approximately 1/3 of the refrigerator.

- At the bottom we have four 100 W bulbs and a thermostat.

- We install the fan so that the air flow, passing through the light bulbs, heats the eggs.

- A container of water is placed at the bottom of the finished incubator.

Take note: It is recommended to solder arcs of wire onto a container of water, on which, like on a clothes dryer, you can hang wet gauze to increase the evaporation area.

The semi-automatic option for making an incubator will save your time and allow you to incubate a large number of eggs at once without additional labor costs.

From this video You will learn how to make an incubator from a refrigerator with your own hands:

Currently, both rural and urban residents raise poultry. All amateur poultry farmers are faced with the need to raise chicks. Special industrial incubator devices for hatching birds artificially are quite expensive.

Most people involved in poultry farming think about constructing their own incubators. There is a variety of experience in their construction in the form of barrels, ovens, etc. And today we will learn how to make an incubator from a refrigerator with our own hands in order to get rid of the need to buy such a device in a store.

Primary requirements

To create this device you need:

- About 10 days should pass before the chicks hatch directly;

- During this decade, eggs are stored 1-2 cm apart at a temperature of 37.3-38.6 degrees;

- Humidity at the time of egg hatching should be 40-60%, and then during the hatching process - approximately 80%. As a rule, before chick collection begins, humidity should be reduced;

- The location of the eggs can be twofold;

- When hatching chicks of ducks and geese, the angle of inclination should be 90 degrees;

- If the eggs are located horizontally, then they are moved from the starting point at an angle of 180 degrees. They are rolled at least three times during the day, and optimally every hour. Before the eggs are laid, which is 2-4 days before they hatch, it is not recommended to move them in trays at all;

- Artificial ventilation is important for incubation. With the help of ventilation, temperature and humidity are regulated. Ventilation speed reaches 5-6 m/sec;

- Incubation brings the artificial chick hatching environment closer to natural conditions.

Construction

Do not rush to throw away a broken, unnecessary refrigerator. It is freed from the old freezer and other parts. In the future, it will be necessary to connect the device to a network with a voltage of 220 V. We take an electric contact thermometer and a KR-6 relay or other modifications. The coil resistance power should not exceed 1 W. We connect it ourselves this design to the network and turn on lamps L1, L2, L3 AND L4. These lamps increase temperature regime up to 38 degrees. The KR coil, connected to the electrical network, opens the KR2 contacts. The process is updated as the temperature drops. L5 lamps warm up all bird eggs equally and contribute to optimal humidity air. After the initial heating of the eggs, it is necessary to continue to maintain the air condition using several lamps. Here it is very important to reduce the operating frequency of the contactor-relay as much as possible, as can be seen in the photo.

The designed device should not consume more than 40 W.

It is not necessary to equip the incubator with a fan; you can also rely on natural air circulation.

Eggs can be moved and rolled either manually or using a special egg turn 3-4 times a day, as seen in the photo.

Using the freezer from the Orsk-50 refrigerator, you can fill it with up to 60 eggs. Chicken eggs are placed in cardboard trays with the blunt end up in a vertical position. After nine days, the temperature should be reduced to 37.5 degrees, nineteen - to 37 degrees.

There are power outages. In these situations, lamps can be replaced by dishes with hot or warm water. Do not heat the water too much.

Frame

You can use TV packaging as the frame for the incubator. The inside of the frame is reinforced with slats and reinforcement, as shown in the video. Four cartridges with low-power lamps are placed inside the frame to warm and moisten the eggs. For fire safety It's better to take porcelain cartridges. The middle lamp is connected during the period of weakening of the electrical voltage.

You will need a humidifier, for this you can use a simple jar, the air evaporates well in it, and the eggs do not overheat.

There should be about 19 cm from the lamp to the eggs, and 15 cm under the grill. You can use a very ordinary thermometer.

The outer wall must be removed and inserted, it is better to cover it dense material. A bathtub is attached to the wall. An 8 x 12 cm hole is made directly on the incubator lid to monitor the temperature and ventilation.

Base

At the base of the incubation structure, 3 open ventilation holes of 1.5 x 1.5 cm are made. No more than half a glass of water per day is needed. To moisten, place a rag in the bath.

Eggs are placed between the slats in special recesses. The tray is not completely filled, leaving free space for turning the eggs 180 degrees up to 6 times every 3 hours.

For evaporation, 25 or 15 W lamps are used. To facilitate egg hatching, do not turn off the evaporator. Otherwise, due to the hardness of the shell, the chicks will not be able to hatch.

During turning, the eggs also cool. 1-2 minutes is enough for this. During the entire hatching period the chicks maintain a temperature of 39 degrees.

Upper body

The upper body is also covered with mesh. There you also install two 40 W lamps with your own hands. They use not only “spent” hives, but also existing ones. Placed on frames metal mesh, so small that bees cannot penetrate inside. The liner is placed directly above the mesh, where the first layer of eggs is placed - 50 pieces, covering it with canvas or burlap. Bees are excellent natural heat conductors; they regulate the optimal humidity regime.

In a homemade incubator with chicken eggs The hatching of goslings can also be carried out perfectly. The tray is filled with 24-26 goose eggs.

Let's sum it up

A used refrigerator is an excellent tool for creating an incubator with your own hands. This improvement is effective and economical, and has great practical value. This will save you money that would otherwise be spent on buying an incubator in a store.

Breeding poultry is a very exciting activity.

A homemade incubator is a very useful invention and also economical.

Hatchery devices, which are manufactured in special factories, are not cheap, and those who want to start breeding poultry often cannot afford to purchase such equipment.

There is a varied range of inventions of incubation devices made from barrels, ovens, etc., but we will talk specifically about the incubator from the refrigerator.

Therefore, this article will tell you in full how to make an incubator with your own hands.

Basic requirements that must be followed when using an incubator from a refrigerator, as well as a diagram of this device

The main advantage of a refrigeration incubator is that factory refrigerators have a very important thing - thermal insulation.

In order to begin the process of manufacturing such a device, you first need to decide on the number of eggs that you will load into the incubator; for beginning poultry farmers, the optimal number of eggs would be no more than 50.

Requirements guidelines that must be followed when using an incubator:

- The number of days that must pass before the chicks hatch must be at least 10.

- During these ten days, the eggs should be kept about 1-2 centimeters apart from each other.

- The temperature for ten days must be no less than 37.3 degrees and no more than 38.6 degrees.

- During egg hatching, the humidity should be about 40-60%. Further, when the chicks begin to appear, the humidity is increased to 80%. As follows, at the time of chick selection, the humidity is reduced.

- The eggs should be in a vertical position with the pointed tip down or in a horizontal position. When positioned vertically, eggs are placed in the tray at an angle of 45 degrees.

- If you are trying to hatch duck and geese chicks, the eggs should be positioned at a 90 degree angle.

- If the eggs in the tray are located horizontally, then they are turned over at an angle of 180 degrees, depending on their initial position. It is best to carry out this rotation every hour, but at least once every three hours. Before the chicks hatch from the eggs, which is about three days before they hatch, it is better not to roll the eggs.

- Ventilation is very important for a homemade incubator. With the help of ventilation, the temperature and humidity of the air in the incubator are regulated. The approximate speed should be about 5 meters per second.

- The incubation method of hatching chicks is very close to the natural method.

Incubator diagram or what it consists of

No one needs to throw an old refrigerator into a landfill; it can be used to make an incubator for hatching poultry.

old The freezer compartment should be removed from the refrigerator. When using an incubator, you will need to connect to a 220 V network.

To construct the device you will need the following parts: an electric contact thermometer, a KR-6 relay or you can take any other models, lamps.

The coil resistance power should not exceed 1 W. The assembled structure must be connected together with the lamps to the network. Lamps for the incubator are used L1, L2, L3, L4, which maintain temperatures up to 37 degrees. The L5 lamp heats all eggs located in the incubator equally and also maintains optimal humidity.

The coil used opens the contacts KP2, and when the temperature in the incubator decreases, the process is repeated. After using the incubator for the first time, it is necessary to maintain the temperature regime with several lamps turned on constantly.

Made fixture should not consume more than 40 W of energy.

When designing an incubator, you can use both natural and artificial air circulation.

Eggs located in the incubator can be roll with hands, as well as using a special device.

There are situations when the electricity goes out, so you can put a bowl of warm water in the incubator, which will replace the lamps for a while.

What can a frame be made from?

The frame can be made from TV packaging. It is reinforced inside with reinforcement or rivers. Inside the resulting frame, you can place sockets with lamps of not very high power to maintain normal humidity and temperature. Porcelain cartridges are best suited.

You can use a jar of water to humidify the air.

The distance between the lamp and the eggs should be 19 centimeters.

The distance between the gratings can be about 15 centimeters.

To check the temperature in the incubator you can use ordinary thermometer.

The outer wall of the incubator must be removed and covered with thick fabric material. A bathtub needs to be attached to the side wall.

A hole of 8x12 centimeters is made at the top of the incubator to monitor the temperature and for ventilation.

What should be the base of the incubator?

At the base of the incubator you need to make three small ventilation holes size 1.5x1.5 cm. The amount of water required per day is no more than half a mug. Eggs are placed in the recesses between the slats, but not tightly to each other, so that a 180-degree turn can be made.

In order for evaporation to occur, 15 or 25 W lamps are used. To make it easier for chicks to peck through hard shells the evaporator should not be turned off.

When the eggs are turned, they cool, two minutes are enough for this. Throughout the entire period, the temperature in the incubator must be maintained at 38.5 degrees.