How to make an electric jigsaw at home. How to make a homemade jigsaw in your home workshop

A tabletop jigsaw is an indispensable item for any owner who is used to doing household work on his own. Electric jigsaws are especially good for residents of the private sector, hobbyists manual labor and country holidays. The desktop electric model has gone quite far from its prototype, an ordinary manual jigsaw. A desktop jigsaw makes it easier and faster to cut, not to mention improving quality.

Concept of a tabletop jigsaw

A jigsaw is a saw, which is characterized by reciprocating movements of the saw blade, which acts as a working body. It has a ski designed to guide the saw blade when moving along the surface that is being processed, and makes movements at a frequency of up to 3000 vibrations per minute.

This instrument was invented in 1946. Its creator is Albert Kaufman, who replaced the needle in a sewing machine with a blade. The instrument went on sale already in 1947. A manual jigsaw has a body with a flat platform and a handle. Main difference electric jigsaw from the manual one lies in its greater functionality and cutting quality.

Located inside Electrical engine and a special mechanism that drives the blade. In stationary jigsaws there is no handle, and the platform is located on top. At the front of the mechanism there is a guide, at the bottom there is a retractable blade that moves and makes cuts.

The tool works in the following way: The table jigsaw blade is securely secured with clamps in the slide. The reciprocating movements have a frequency of up to 3000 strokes and can be adjusted. The support platform allows the jigsaw to focus on the part being cut, so the work is carried out very accurately.

The purpose of a desktop jigsaw

A jigsaw is an integral part of every workshop and every hobbyist. Its thin file can successfully cut plywood, copper, iron, thick boards, brass, and steel. The tools come with motor, foot or hand drive and are more productive. An electric jigsaw is simply indispensable for carpenters, wood workers, furniture decorators, and drywall workers who produce complex parts.

An electric jigsaw can make straight and curved cuts on workpieces with complex shapes and various sheet materials without disturbing the external contour. Most often, tabletop jigsaws are used for cutting wood and wooden boards, figures with complex outlines made of laminate and plasterboard, plastic blanks, and also for cutting sheet metal.

The benchtop electric jigsaw makes clean cuts in complex shapes and works on small

details. Due to the stable and fixed position during operation, it is achieved high accuracy cutting The file has a stable motion thanks to the tension system and guides, which manual jigsaws lack. Big size The table makes it stable, so the precisely specified sawing direction is maintained.

Types of jigsaws

Today, the power tool market offers a wide variety of jigsaws, which differ in the nature of their application, technical specifications, type of power supply and design features. In construction stores you can buy a tabletop jigsaw for every taste and budget.

It is difficult to classify by design features, because each manufacturing company strives to provide its products with features that are designed to facilitate and improve the operation of the tool. In this regard, the shape of the handle is a significant parameter.

There are two established types of handles - mushroom-shaped and D-shaped. A jigsaw with a staple handle requires one-handed operation. This increases the possibilities of using a jigsaw, but has a somewhat negative effect on the quality of cutting the material.

Mushroom-shaped handles allow for more accurate cuts when holding the jigsaw with both hands, having previously secured the workpiece to be cut. The choice of a jigsaw with a specific handle shape depends on the financial capabilities and personal preferences of the buyer. You should choose the jigsaw that will be more convenient to work with.

Household jigsaws are not intended for intensive use, but the low price of a desktop jigsaw and the power that is sufficient for household needs make them indispensable in the household.

Professional jigsaws are characterized by high wear resistance and the possibility of daily long-term (up to 8 hours) use. The significant power of such jigsaws allows processing of materials of large thickness. Expanded equipment and improved characteristics are reflected in the price.

Among professional jigsaws, industrial jigsaws also stand out, which are characterized by greater adaptability to complex operations and drive features - for example, increased power supply voltage. Industrial models are machines that are designed for the woodworking industry.

Depending on the type of power supply, there are mains and cordless jigsaws. Network models are powered from a power supply network with standard voltage. If productivity is important to you, then you should choose a corded power tool.

Cordless jigsaws provide independence from the presence of sockets and greater mobility during operation. When purchasing a battery model, you should pay attention to the type of battery. Elevated performance characteristics inherent in lithium-ion batteries. The battery capacity is responsible for the duration of operation without recharging.

Advantages of desktop jigsaws

A tabletop electric jigsaw is a stationary design, so this type of cutting tool has many advantages. Modern models can work with wooden materials with a thickness of 40-50 millimeters. The working body is a narrow saw, which makes vertical translational and reciprocal movements. Due to the peculiarities of the notching of the teeth and the mechanics of the movements of the saw, the material is cut out by moving upward.

A tabletop jigsaw allows you to cut out complex decorative parts, make longitudinal, straight, inclined and transverse cuts. Wide table top allows you to process large parts and make cuts inside wide workpieces. Secure fastening protects the housing from unnecessary vibrations and allows the material to be well positioned, so the motor can operate without overload.

The advantages of desktop jigsaws include good accuracy and clarity of cuts, high safety and ease of use, ample opportunities settings depending on the material and the required part of the cut workpieces.

If you need to cut small parts, a manual jigsaw will not be very convenient. It is quite heavy, so you will have to hold it with one hand and guide the workpiece with the other. A table jigsaw does not have this drawback. Perhaps the inconveniences are the large size and the difficulty of working with large parts.

A tabletop jigsaw is a kind of mini-machine for cutting workpieces. If you purchase a jigsaw in a store, most likely it will provide the ability to select power and adjust the frequency of saw strokes. However, you can make a simple homemade tabletop jigsaw, and very quickly. You will need a hand jigsaw, a few screws, a piece of plywood large sizes and only an hour of work.

Making a tabletop jigsaw

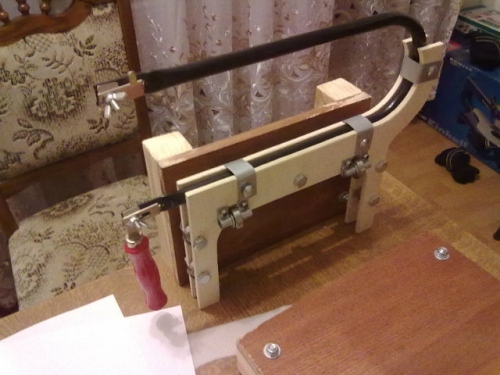

A carefully made jigsaw will be little inferior to one made in a factory, and in some respects even superior to it. Assembling such a jigsaw is not difficult if you have the necessary materials. Next we will describe simple diagram such manipulations.

The design of the jigsaw includes the following components: handle, switch button, insulating washer, power cord, frame, heating filament, screw clamp and earring. First you need to make a frame. You will need a duralumin pipe with an outer diameter of up to twelve millimeters.

You can also use textolite with a thickness of at least ten millimeters or thick plywood for the base. But keep in mind that the lighter the frame, the more convenient the jigsaw will be to use. Be sure to provide a channel so that you can lay the power cord later. Most best shape a frame is one whose sides are tilted 45 degrees.

Next you need to make an earring. It is made of copper sheet one millimeter thick. After this, it is attached with screws to the frame where it connects to the handle. In this way, the screw, wing nut and shackle will form a clamp in which the heating filament can be fixed. The thickness of the duralumin sheet should be up to 0.8 millimeters. It is necessary to make pressing cheeks from it, between which there is a switch button.

After this, you need to cut a gap in the plywood that the saw can fit through. It can be done using a drill. To do this, you need to drill holes along the marking line and smooth out the transitions. Instead of plywood, you can use plastic, metal, plexiglass and others. Next, you place and drill mounting holes on the plywood and jigsaw base plate.

Then you need to secure the jigsaw with screws to the plywood base so that the file can fit through the gap. You attach the structure to the table using a clamp so that the file is pointing upward. You can also secure the platform in any way possible.

The jigsaw file remains a regular one, but the possibilities for good cutting are expanded by freeing up your hands.

You can use a nichrome spiral from any household heating device (iron, for example) as a heating filament. It must be secured with tension between the ends of the frame bends. In order for the thread to heat up, you need to apply a tension of about 14 V. To control the operating mode, you can use a rheostat.

The current is determined by the thickness and length of the nichrome thread. Using a rheostat, you can set the optimal current strength (no more than 3-5 A), which will affect the temperature to which the filament is heated. Before starting work, it is necessary to determine the current strength. But keep in mind that if the force is too high, the cut material may be caught in the flame, but if it is insufficient, it will not be taken. A self-made desktop jigsaw will allow you to cut shapes with complex contours from various types of materials.

Rules for using a desktop jigsaw

When working with a table jigsaw, you must adhere to some rules:

- When cutting, do not press too hard on the tool, otherwise it will best case scenario the needle will break, at worst, you will ruin the work.

- Replace saw blades from time to time. An old saw can damage and destroy the surface of the material.

- If you work with organic glass and non-ferrous alloys, the surface of the product must be moistened with water. This operation will speed up the process and extend the life of the saw.

- If you are cutting a surface with a thickness of less than one millimeter, place a sheet of wood or plywood under the material being processed.

- Before cutting, it is necessary to secure the material. It is better not to make long cuts by hand; the line may turn out to be crooked.

- For cutting different materials appropriate blades are required, with a special pitch and length.

- Rotate the tool by turning only the back of the tool.

- When cutting laminate, tape is applied to the cut line, which protects the material from chipping.

- If there is a need for curved cuts, set the jigsaw pendulum to minimum.

If you have not yet fully understood how to make a tabletop jigsaw, watch a video about this procedure. This tool allows you to cut complex parts from wood and other materials, make longitudinal, inclined, straight and transverse cuts. Using a jigsaw you can process large parts, wide workpieces and small items, which is not superfluous at home.

- Manufacturers, models

- JET JSS-16

- JET JSS-16е

- Craton WMSS-11-01

- Holzstar DKS 501 Vario

- Scheppach SD1600V

- Scheppach Deco Flex

- PRORAB 4000

- Proxxon DS 460

- Hegner Multicut-2S

A jigsaw tool is used to cut various Construction Materials, form shaped parts used in carpentry shops when assembling furniture.

Manufacturers, models

The most commonly used tabletop jigsaws are Bosch, Makita, JET, DeWALT, Corvette, Proxxon, Excalibur, Zubr. The equipment demonstrates stable operation and good performance. Yes, electric jigsaw machine Bosch has a long service life, different high quality assemblies. DeWALT equipment is characterized by smooth, uninterrupted operation. The Zubr table jigsaw is equipped with an adjustable pendulum saw stroke, which improves the quality of the cut surface.

The stationary electric jigsaw machine Enkor Corvette copes with inclined, longitudinal, and cross cuts. The German tabletop electric unit Einhell is sold in 53 countries. Dremel jigsaws are equipped with wide range saw blades, with which you can make parts of complex configurations.

When choosing, you need to study the features of the equipment, know for what purpose the electric jigsaw is being purchased, and how often it will be used.

JET JSS-16 (RUB 10,560)

The JET desktop jigsaw machine is used in home workshops and small carpentry shops for curved cuts of workpieces. It is possible to install saws with different fastenings. The stroke rate range is adjustable from 400 to 1600 strokes per minute. This ensures high-quality processing of plastic, plywood, chipboard, and natural wood.

JET JSS-16e (RUB 12,320)

Jigsaw with asynchronous motor copes with straight and radius sawing of wood of varying hardness and polymer materials. Working speeds - 400–1800 passes per minute. Safety guaranteed by transparent cover, sawdust removal fan ensures cleanliness working area.

Kraton WMSS-11-01 (RUB 5,679)

The machine is designed for forming decorative parts from wood, sawing wood in the longitudinal, transverse direction, along an inclined line. The work table can change the angle of inclination, the cutting file can be installed in two positions. The tabletop jigsaw has a large frame reach, so it can process large workpieces.

Holzstar DKS 501 Vario (RUB 8,700)

The desktop jigsaw is designed for cutting external and internal contours of various configurations, including complex curved shapes. It is also used for cutting parts made of soft wood and plastic bases. The cutting line is cleaned by an adjustable wood dust removal system. It is possible to connect a vacuum cleaner.

Scheppach SD1600V (RUB 9,800)

Distinctive characteristics of the machines - low level vibrations, stable cutting of parts from various materials. You can choose the angle of inclination of the desktop depending on the nature of the work. The compactness of the equipment allows it to be used in small workshops and at home.

Scheppach Deco Flex (RUB 13,975)

The sample is equipped with a flexible shaft, which ensures finishing of lumber. It is used to cut out complex furniture elements. The stroke speed is adjustable in the range of 550–1650 rpm, the cutting depth is 500–405 mm.

PRORAB 4000 (RUB 6,825)

Desktop jigsaws cope with sawing wooden, plastic, and metal workpieces. Are different high resistance: have a wide support base. The cooling system of the working element prevents the saw from overheating due to friction.

Proxxon DS 460 (RUB 34,500)

The jigsaw unit is equipped with a stable cast steel structure and a magnesium rocker arm. To replace the cutting element, the aluminum table moves 8 cm horizontally. The machine can be equipped with saws with pin and flat ends, which ensure high-quality cutting of wood, plastic, metal, and plexiglass.

Hegner Multicut-2S (RUB 52,720)

A professional electric jigsaw is easy to use and has a clean cut. The unit is equipped with a set of original saws capable of cutting wood, polymer materials, metal blanks. If desired, the machine model is supplemented with a speed controller, which increases the cost.

The table shows the characteristics of the models trademark"Bison" and jigsaws "Corvette".

|

Power, W |

Number of strokes/min |

Wood cut depth/mm |

Price, rub. |

||

|

Bison ZSL-90 |

|||||

|

Bison ZSL-250 |

|||||

The process of shaped or straight cutting of a large volume of materials, even of small thickness, can be very energy-consuming and time-consuming. In this case, a more advanced, stationary analogue, which has necessary indicators for confident work. In this article we will look at how a jigsaw machine works, what characteristics it has and how wide the functionality it can have. Also, at the end of the publication, we will provide a rating of quality, inexpensive models, suitable for amateur and professional use.

What is a jigsaw machine

A tabletop jigsaw is a powerful device for longitudinal and shaped cutting of wood and other materials of small thickness. It consists of a rectangular base with a working surface and a rigid, metal frame. An electric motor located at the base transmits movement to the saw using the principle of a crank mechanism. The operating principle of a jigsaw machine is reminiscent of a sewing machine, which became the prototype for the creation of this device.

The scope of application of a stationary jigsaw is as similar as possible to its more primitive manual ancestor, except that the former is used for more professional work. If you do not take into account the obvious design differences, and focusing only on the capabilities of the devices, we can highlight several significant features.

- When working on a jigsaw, unlike a manual one, the operator has both hands free, which allows more precise control of the position of the product during cutting.

- The effectiveness of using a manual jigsaw depends on the skill and physical data of the person. Prolonged work with such a tool is significantly exhausting.

- Most models of jigsaw machines are equipped with a tilting working surface, which allows you to cut the workpiece at a certain angle. Accurately performing such a task manually requires some experience.

Files for a jigsaw

The most important working element, which requires the most frequent replacement during operation, is the saw blade. The duration of its use and the quality of the final result depend on the characteristics of this consumable. To work on a jigsaw, files with flat ends are used. Unlike a manual jigsaw, blades for the machine have pins installed at the ends for more convenient installation and tension. Otherwise, the files installed in a manual and stationary jigsaw are identical in size and shape.

More detailed description We have provided varieties of saw blades for a hand jigsaw and a selection guide in a separate publication on our website.

Main characteristics

There are several generally accepted indicators that determine the capabilities and efficiency of a jigsaw machine. Before choosing a device based on certain data, you should set clear criteria in advance and determine the approximate scope of work in which an electric table jigsaw will be used. It’s worth answering whether you need a powerful and expensive machine capable of cutting thick bars and sheets of metal, or whether a budget option with a high speed of cutting small workpieces will be sufficient. The more specific the answer to this question, the more profitable purchase you can make. To select the most optimal device, we provide the following data.Power

One of the most important indicators influencing the operation of an electric jigsaw is the power of its motor. The higher its value, the thicker and dense materials he can saw. The average power rating for models costing up to 10,000 rubles is only 90 watts. Compared to a conventional electric jigsaw, where the average value is 450 Watts, the indicator of a stationary analogue does not seem serious, but in fact, this power is enough to confidently cut wood up to 50 mm thick.

Although the power indicator plays an important role when purchasing, in order to understand how to choose a jigsaw that meets your requirements, you need to understand the other characteristics.

Cutting depth

Another important indicator that determines the maximum thickness of the material being cut. In most cases, the maximum value for wooden blanks is 50 mm. Basically, this thickness is determined design features a device whose frame simply physically does not allow placing a larger product underneath it. At the same time, when we're talking about When working with metals or plastics, the power indicator at the cutting depth plays a key role. Average values in budget models are 6 mm for steel and 15 mm for PVC.

Number of moves

The value of this parameter determines the speed and accuracy of cutting the workpiece. The more reciprocating movements your machine makes per minute, the fewer chips are formed on the wood, and the cut line is smoother. Average number of moves for most stationary jigsaws costing up to 10,000 rubles is 1,500 per minute. When using special saw blades (double missing teeth), given value enough to get a clean line.If you intend to produce high-quality products and you need a good tabletop jigsaw for artistic cutting, you should pay special attention to the frequency of the saw stroke. The higher this indicator, the better.

Desk dimensions

The convenience of working with large workpieces depends on the size of the work table of a jigsaw machine. This indicator does not determine maximum length cut (this is indicated by the clearance to the frame), but it significantly facilitates the manipulation of large sheets of materials. The average size of the working table of budget stationary jigsaws is approximately 350 mm in length and 250 in width. It is worth paying attention to the dimensions of the site if you plan to work with large materials.

Additional functionality

The presence of additional functionality expands the capabilities of any device and a jigsaw is no exception. of this rule. Special regulators and accessories make the device more versatile, increasing its cost, but at the same time, labor efficiency. For the convenience of performing certain operations, stationary jigsaws for wood are equipped with a pedal, a backlight, a dust collector, a mechanism for tilting the work table, and even an engraver. Let's take a closer look at all the delights of modern jigsaw installations.Speed adjustment

One of the most common additional functions, most commonly found in tabletop jigsaws. Adjusting the speed allows you to adjust the frequency of reciprocating movements made by the saw blade in one minute. This function makes the device more versatile, allowing high-quality cutting of materials of varying degrees of density. For example: with wood and its derivatives, you can work on maximum speed, For PVC is better set the average value, and it will be more correct to cut metal at minimum speed, to extend the life of the saw blade.

There are two types of speed controller: smooth and stepped. The first type allows you to set the most precise frequency of movements, and with the help of the second you can only switch between several speeds provided by the manufacturer. Both options have a right to exist, but in the case of the second, it is worth paying attention that there are at least 4 speeds. Sometimes you come across models of jigsaw machines with a speed controller of only 2 speeds, which does not particularly expand the capabilities of the device.

Work surface tilt

When a product requires cutting at a certain angle, the tilting function of the working surface comes in handy. This mechanism allows you to set the required angle of inclination of the desktop, up to 45°. In the majority budget models Bench jigsaws are tilted only in one direction. In more professional devices, this function works in both directions. The ability to set the cutting angle in modern machines is becoming more and more common, but there are also models where it is absent.

Backlight

The cutting process is much more efficient in a room with good lighting. If it is not possible to illuminate the entire room brightly enough, built-in lighting comes to the rescue. This simple function, provided in some models of jigsaw machines, greatly facilitates the work process, saves vision and saves time that you could spend on independently organizing the lighting of the work area. Of course, this function is not decisive in choosing a stationary jigsaw, since you can do it yourself if you wish, but a neat spotlight will be an undoubted advantage of any model.

Dust extraction

When cutting, even a small volume of material, a fair amount of sawdust forms on its surface. In addition to the fact that this waste from the work process covers the contour being sawed, due to the vibration of the machine, it partially enters the air and the operator’s respiratory tract. In order to ensure a comfortable working process without dust and shavings, many models of stationary jigsaws are equipped with special dust extractors, to which you can connect a vacuum cleaner to suck up sawdust.

An additional option for removing sawing waste is a flexible rubber pipe. This element is connected to a small compressor, and unlike a dust extractor, it does not suck in dust, but blows it away in the specified direction. It is better to wear a respirator when working on a machine with a similar function. Many models of tabletop jigsaws have both sawdust removal functions at the same time.

Flexible shaft (engraver)

One of the most interesting and useful functions, in most cases inherent in professional models. Allows you to drill, grind and polish products without the use of third-party tools. The main advantage of a flexible shaft is the almost complete absence of vibration. Among the disadvantages, we can note a single drive that starts the saw blade and the engraver at the same time. For safety reasons, when working with a flexible shaft, the saw blade should be removed from the fastening element. The average number of revolutions of the nozzles per minute is 2500, which can be reduced or increased using the speed controller.

Rating of desktop jigsaws

Among large quantity of the products offered, it is quite difficult for an inexperienced buyer to make an unambiguous choice of a tool that meets all the requirements. By and large, this statement applies to such technologically complex devices as jigsaw machines. When choosing this device, you must have clear requirements for technical characteristics and additional functionality. In addition, it is worth reading reviews from previous customers, comparing people’s opinions with your expectations.To make the selection process easier, we have collected 5 proven models of budget jigsaw machines costing up to 10,000 rubles. The devices listed below belong to the budget category, but they cope with their task 100, or even 150 percent.

BISON ZSL-90

One of the most budget-friendly jigsaw models from a domestic manufacturer. Quite noisy in operation and has decent vibration. It copes well with cutting plywood, chipboard and thin wood. Suitable for amateur and household use. Well worth the price.

Guarantee: 5 years

Price: 6000 rubles

ENCOR Corvette-88

A fairly quiet table jigsaw with a minimum of vibrations. It has a design with a large frame reach for working with large workpieces. It has a stroke frequency adjustment with two speeds, which allows it to be used for working with plastic. There is no dust collector, but there is a pump for blowing sawdust. Optimal and inexpensive option for performing longitudinal, inclined and figured sawing of massive products.

Guarantee: 12 months

Price: 7500 rubles

Dremel Moto-Saw (MS20-1/5)

A very fast, electric desktop mini jigsaw from an American manufacturer. Thanks to its prefabricated design, it can be used as a machine and as a portable tool. It has a miniscule stroke of the saw blade, due to which the cutting line turns out to be very smooth and neat. Primarily intended for decorative and figured sawing small parts made of wood, plastic and metal, but can also be used to solve more practical, everyday problems.

Guarantee: 2 years

Price: 7800 rubles

Einhell TC-SS 405 E

A decent jigsaw machine for performing straight, curved, inclined and cross cuts of various materials. It has an average level of noise and vibration, which is significantly reduced by mounting the device on a workbench. The working surface is made of plastic, albeit of fairly high quality. It is equipped with good additional functionality, which makes this jigsaw universal in its field of application.

Guarantee: 2 years

Price: 8500 rubles

JET JSS-16A

Perhaps the most reliable representative of budget desktop jigsaws. It has a durable cast body and an aluminum work surface. Distinctive feature This model allows you to use files with or without pins. During operation, the machine produces a low level of noise and vibration, acceptable for comfortable operation. Worthy and functional option for the home workshop.

Guarantee: 2 years

Price: 9000 rubles

Save this page on your social media. network and return to it at a convenient time.

A tabletop jigsaw machine will be useful to every craftsman who cuts out thin parts. However, it is not always possible and meaningful to purchase a full-fledged machine. In that case, get down to business and make it yourself!

The structure of a jigsaw machine - what lies inside?

Jigsaw machines are more related to special tools than to devices that are needed as to an experienced master, and for the amateur who manages the garage. Their purpose comes down to a special task, namely cutting out complex curved contours from sheet materials. A special feature of such machines is the execution of cuts without violating the integrity of the external contour. Most often, sawing occurs on wooden and derivative materials (plywood, chipboard, fiberboard), although modern machines equipped with appropriate saws can also work with other materials, for example, plastic or plasterboard.

Such equipment has found application in the music industry (manufacturing musical instruments) and, of course, in the furniture room. Those who like to make things in their own workshop also buy such units. The structure of a traditional jigsaw machine, designed according to all the rules, looks like this: working surface, on which the saw is mounted, hides the drive (electric motor) and the crank structure underneath. The tension mechanism can be located either below or above the machine.

To process a part, it must be placed on the workbench. Many models have the ability to rotate it under different angles to make bevel cuts. The stops and guides on the surface, as well as the rotating mechanism, can be marked, which greatly simplifies and speeds up the work. The length of the cut depends on the length of the work table - most models are limited to 30-40 cm. Electric motor power is an important, but still far from the most fundamental factor, since the machine has a huge reserve of unclaimed power. For example, for a home workshop or even small production, an “engine” of only 150 W is sufficient.

The crank mechanism is much more important detail, because in in this case It is on this that the quality of transmission of the drive’s torque into the translational and reciprocal motion, directed in the vertical plane by means of a saw, depends.

Standard jigsaw machines are considered to be devices with an amplitude of movement of around 3-5 cm and a vibration frequency of up to 1000 per minute. Many models provide a change in speed mode for different materials. The jigsaw file itself is usually made up to 35 cm long and is capable of sawing material up to 10 cm thick. The width of the files can vary in a fairly wide range - from very thin two-millimeter to coarser ten-millimeter, with a thickness from 0.6 mm to 1.25 mm.

Even the thickest and widest file will easily break if you do not provide sufficient tension along the entire length of the file. Leaf and coil springs are used for this. Quite often, such machines are equipped with an air pump, which cleans the cut from sawdust by blowing it, as well as a drilling unit. The latter device is especially useful, because in this case the master does not need to be distracted by connecting an electric drill and drilling a hole - everything happens on the working plane of the machine. Of course, you have to pay for convenience!

How to make a jigsaw with your own hands from a manual jigsaw?

On the Internet you will find many different designs homemade machines, but most of them come down to repurposing into this device. By using your ingenuity and watching the video, you can easily make a homemade jigsaw from this tool. The jigsaw only needs a little modification. In fact, it plays the role of a machine drive and a crank mechanism, but the rest needs to be thought out and implemented.

Of course, manufacturers are trying to please consumers in this area as well, offering their own platform options for quick and convenient remodeling, however, in reality only you can make a device that suits your needs. So, the first step is to make a support table, for which sheet metal is most often used. You need to make a beveled oblong hole in it for the saw blade and holes for fasteners (countersunk screws are recommended), and attach the jigsaw to the bottom of the support table.

This structure can only be strengthened on a wooden table. You can go beyond this and install guide rails. The convenience of such a device lies in the fact that in addition to performing functions that are not entirely inherent to it, you can always disconnect the drive and with a slight movement of your hand turn it back into a manual jigsaw! If you constantly need this tool for work, it makes sense specifically for the machine - it will be cheaper than spending money on a real machine.

Advantages and disadvantages - we continue to modify!

But such a unit inherits not only the advantages of the tool, but also its disadvantages, in particular, the file is too wide for filigree work, which significantly limits the curvature of the lines. If there is a need for this, there will be a way out. So far, our machine differs from the classic jigsaw unit in the absence of springs that would ensure sufficient tension on the file. But it’s quite easy to build a simple rocker, which on one side will be under the tension of springs, and on the other, fixed to a nail file.

There is another option - to clamp the nail file between two guide rollers, but the first option is still more reliable. Be sure to turn off the pendulum action on your jigsaw before using it. homemade machine. There is another design - if your tool is powerful enough, then it can only serve as a drive in a structure of two rocker arms, between which a nail file is stretched. The movement is transmitted through a file attached to the lower rocker.

Machine from a sewing machine - giving a second life to old tools!

If you inherited a foot or hand weapon from your grandmother or mother sewing machine, consider yourself the owner of an excellent jigsaw! Of course, for this you need to “work a little magic” on the machine. First, remove the thread weaving device, which is usually located at the bottom of the machine. There is nothing complicated about it, just unscrew two bolts. Then we knock out the cotter pin and remove the drive shaft leading to the thread weaving mechanism.

Having unscrewed the top panel that protects the mechanisms, it is necessary to expand the slot in which the needle went. Be guided by the needs and width of the nail file that you will use in your work. Files for a jigsaw machine of this kind also need to be slightly modified, namely, cut to the maximum length of the needle that could be used on this machine. Grinding off the upper teeth and sharpening bottom part on the tip, all you have to do is insert the file into the needle holder and test your machine in action!

By making a jigsaw with your own hands, you will not only be able to purchase a practical tool, but also save money. cash: it will be much cheaper than the factory analogue, while possessing a full range of functions. A homemade jigsaw will allow you to create products of complex shapes from wood, plastic and other materials, the production of which with hand tools in normal conditions would take a lot of time and effort.

A homemade jigsaw allows you to make cuts of complex shapes.

You should consider the structure and sequence of manufacturing a simple tabletop electric jigsaw, assembly features and the procedure for working with it.

How does a tabletop jigsaw work?

As the name suggests, this tool is designed to be placed on the surface of a desktop or workbench. Compact dimensions allow you to work with a jigsaw both in a workshop or garage, and at home. The electric jigsaw is an indispensable tool for making complex wood decorations, figured plywood carvings and similar works.

Kinematic diagram of the jigsaw drive.

It is necessary to take a closer look at the structure of a factory-produced desktop jigsaw. This will allow you to understand the main features of the device and apply them in a homemade model.

The components of an electric jigsaw can be divided into 3 parts:

- movable frame with saw;

- fixed base;

- Electrical engine.

The operating principle of the tool is as follows: an electric motor rotates a crank mechanism, which converts rotational movements into reciprocating movements. The movements are transmitted to a movable frame on which the saw is tensioned.

The homemade device works using the same principle. To simplify the design, the movable frame can be replaced with a regular hand jigsaw.

Return to contents

Parts for electric jigsaw

When assembling an electric jigsaw, it is important to find a suitable motor that will drive the working tool - the saw. A motor from a drill, blender, etc. is perfect for this purpose. food processor or other equipment of the same type.

It is better to make the jigsaw frame from aluminum pipe.

The movable frame is made from metal profiles, wooden slats or slats made of durable plastic. It is most convenient to work with aluminum tubes of square section, since they are easy to process, have low weight and a significant margin of safety.

To fix the jigsaw in the desired position, you should make a reliable frame for it from wood or metal. The dimensions of the frame do not have much impact on the operation of the jigsaw. They depend only on which version of the tool you need - a compact tabletop or a full-size one installed on the floor.

The jigsaw table is made from a thick sheet of plywood, in which a small diameter hole is made where the saw will move (Fig. 2).

A gasket made of elastic material - rubber or leather - is placed between the body and the table, which will dampen vibration.

There is also a simpler option on how to make a homemade jigsaw. It consists in the fact that a hand-held electric jigsaw is mounted in a vertical position on a table-stand, while its file is tensioned to the movable guide bars - levers.

Return to contents

Assembling a table jigsaw

The construction of a homemade jigsaw begins with assembling the body, which can be made of plywood, chipboard or metal. The most simple model This tool can be used without a housing, but in this case strong vibrations occur, which can significantly affect the ease of use. In this case, two holes are made in the jigsaw - one for attaching the crank to the tool, the second for movably fixing the jigsaw itself to the table. After starting the engine, the jigsaw begins to produce reciprocating movements that facilitate sawing of the material.

Such a spring will provide the necessary tension on the jigsaw saw.

A more sophisticated model includes two separate strips with wing nuts installed at the ends. At the opposite end, the planks are pulled together by a strong spring, ensuring constant tension on the saw. Such a device operates from a separate motor or, for example, from a drill.

There is a vertical bar running inside the case, which is fixedly attached to its bottom or one of the walls. Two holes are made in it, the distance between which should be 2-3 cm less than the length of a standard file. Bolts or pins are inserted into the holes, onto which strips are placed that hold the file.

The engine is built into the housing and is attached to the bottom bar by means of a disk with a connecting rod mechanism. A table with a hole for a file acts as a cover for the case.

The main disadvantage of a jigsaw with a separate motor lies in its most intricate part - the crank mechanism. The file with it makes not only vertical, but also oblique movements, which cannot but affect the cutting accuracy. If you need to get a precise tool, then it is better to replace the engine with an inexpensive factory-made manual jigsaw. It is attached under the surface of the body and a file is passed through the table, clamping it with one end in the jigsaw and the other in the upper bar of the structure. This design ensures sufficient cutting accuracy, bringing this parameter closer to factory models.

Return to contents

Advantages of using an electric jigsaw

A jigsaw allows you to make complex cuts very accurately.

Unlike hand tools, an electric jigsaw has clear advantages, including:

- more high speed work;

- the ability to work with two hands, which increases accuracy;

- safety - with proper organization of work, a stationary tool is much safer, since it cannot break out of your hands.

Besides, self-production An electric jigsaw will save money, since factory machines of this type are quite expensive.