How to shorten a chainsaw chain with your own hands: sequence of actions, nuances of the process and video instructions. What does a lock on a bicycle chain look like?

Often during operation of a chainsaw, the saw chain stretches, which makes further use of the tool impossible. Today, there are specialized workshops that provide services for shortening chainsaw chains, but it is possible to shorten a chainsaw chain with your own hands at home or right at the workplace.

Reasons why chain stretching occurs

A chainsaw chain, regardless of the manufacturer, can stretch for several reasons:

- Incorrect operation of the oil pump. The supply of oil in insufficient quantities leads to overheating of the chain and its rapid stretching.

- Natural wear and tear. Occurs as a result of prolonged use of the tool.

- Using poor quality lubricant.

- Violation of the rules for operating a chainsaw.

Important: If malfunctions in the operation of the oil pump are detected, it is necessary to eliminate the malfunctions and ensure normal lubrication of the saw blade. Failure to do this may result in drive sprocket failure. You should also pay attention to the quality of the oil. The presence of various types of abrasive microparticles in the oil is not allowed.

Tools needed for shortening

You can properly shorten a chainsaw chain with your own hands using special tools.

Rivet removal machine

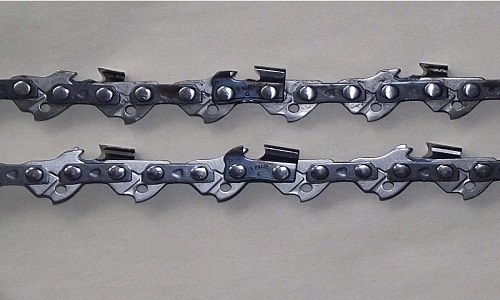

For disassembly, a specialized machine is used - a punch. The machine is made in the form of a small mechanical press. A removable anvil with grooves is installed in its lower part different sizes. The working rod of the device also has attachments different diameters. It does possible use machines for chains from various manufacturers. The rivet is removed by squeezing it out seat.

Attention: the diameter of the removable tip of the working rod should not exceed the diameter of the hole in the side plates.

Riveting machine

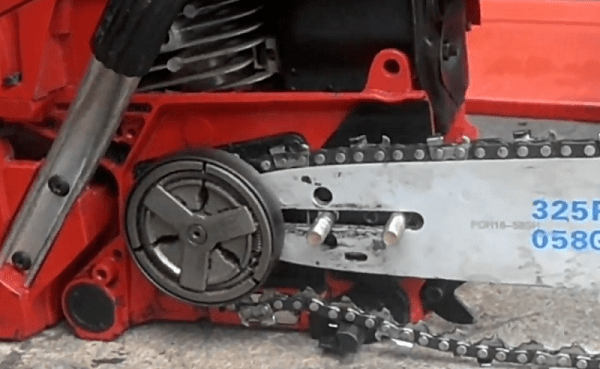

After disassembling and removing the chain element, it is necessary to reconnect the working links. A riveting-rolling machine is used for this purpose. The assembly process takes place using a special work roller, which is driven by an electric motor.

The rivet is clamped between a stationary anvil and a working roller. The operator independently sets the pressure of the working roller using an adjusting screw. As the roller rotates, the edge of the rivet is gradually crushed, making it impossible to separate the links from each other.

Reference: Using machines to shorten the chainsaw chain allows you to bring the build quality as close as possible to the factory model. However, these devices are quite expensive, and purchasing them for use at home is unprofitable. In addition, it is not always possible to use specialized devices directly at the workplace. In this regard, shortening can be done with improvised tools.

Methods for removing rivets without the use of specialized devices

You can remove rivets without using specialized tools in several ways:

Removing a rivet using a file

- Grind down the ridges using sandpaper. When using this method, it is necessary to control the degree of pressure on the rivet to avoid damage to the working parts.

- Cut with the cutting wheel of an angle grinder. It is worth considering that in this case the metal heats up, which will affect its properties.

- File off the heads using a file or needle file. With this method, the risk of damage to the links is minimized.

- Cut using a chisel. Before starting work, you will need to securely secure the chain in a vice.

After the outer protrusions are completely cut off, you will need to knock the rivet out of its seat. To do this, you need to select a punch whose diameter will correspond to the diameter of the hole. The punch must be placed on the rivet and knocked out with a sharp blow of a hammer. After completing these steps, the circuit will be disconnected.

Attention: To avoid damage to the links, they must be securely fastened. In addition, the punch should be installed strictly perpendicular to the cut of the rivet.

How to rivet a chainsaw chain

To assemble the chain, you will need to install a repair link on it. It must be taken into account that its dimensions must strictly correspond to the dimensions of the working links. Installing a spare part with a different pitch or profile can lead to damage to the drive, driven sprocket and saw blade of the chainsaw.

The repair link is sold with rivets that simply need to be secured. To do this, you need to place the chainsaw chain on the anvil. After this, place the punch on the new rivet and flatten the head with a sharp blow of a hammer. It is necessary to rivet until the resulting thickening covers the hole in the outer plate.

When flattening, you should control the degree of clamping of the side plates. After assembly, the installed link should move freely along the axis. Installing a chain with a jammed link on a chainsaw is not allowed. Neglecting this rule may lead to more serious damage to the device.

Some people use electric arc welding machines for assembly. In this case, the edges of the rivet are welded to the outer plates of the link. The use of electric welding involves heating the metal to high temperature. As a result of overheating, the properties of the metal change and it becomes less wear-resistant.

From the information described above, it follows that stretching the chain on a chainsaw is quite common occurrence. It is quite possible to shorten a chain at home; you just need to get hold of traditional tools, which are available to almost every owner.

The condition of the chainsaw chain must correspond technical requirements its operation. Any defect, be it sagging of the chain or deterioration in the quality of the cut, often occurs due to its stretching.

From the point of view of operator safety, further operation of the chainsaw is not permissible. At the most unexpected moment, the slack chain can break and cause injury to him. It is necessary to replace it with another spare chain, or to shorten it in a workshop or workplace.

Is it always necessary to repair the chain?

A sagging chainsaw chain is not always a reason to repair it. You must first make sure that it is definitely not subject to tension (adjustment).

Here are some typical cases:

- Chain stretches.

- The new existing circuit does not match the short bus.

Find out how to make a router from a drill with your own hands:

Chain stretching due to prolonged operation is a typical case. During operation, the metal of the chain heats up, and the links gradually stretch due to the expansion of the metal in volume. That is, the chain is stretched every time, which can sometimes be eliminated by partially reducing the cutting time. However, this is not an option when she has to work intensively for the entire shift in an industrial environment or when collecting firewood for the winter.

Another circumstance that does not allow the saw to be used normally even with a new chain is the discrepancy in length. This can only happen when purchased by inattentive users, or is caused by the current lack of the required chain. Which, in principle, is not so dangerous, since you can always find a way out by shortening it manually. At the same time, the strength of the connection of the chain links will remain at a fairly high level.

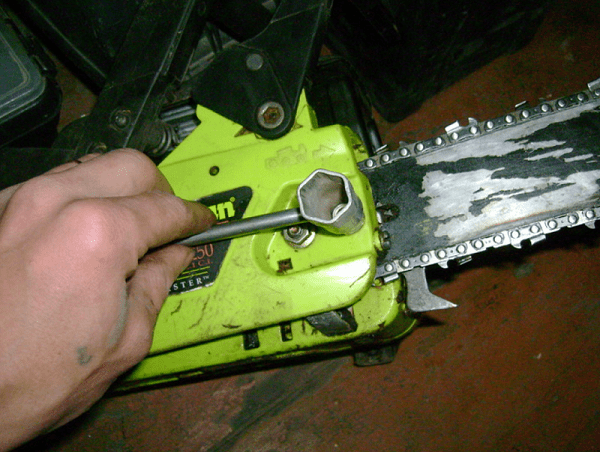

Adjustment of chain tension is usually done manually using the saw tension bolt located in the area of the dog teeth.

Using a straight screwdriver mounted on the bar and drive chain, after closing the side cover, begin to gradually tighten.

You should not tighten the chainsaw chain all the way, as you risk stretching the links again soon. Usually, a small reserve of chain stretch is left, which can be checked by hand. It should be slightly retractable from the tire by about a millimeter.

If there is a need to shorten

Often, when working in the forest or on a remote construction site, you will not be able to find a replacement for a stretched chain.

Often, when working in the forest or on a remote construction site, you will not be able to find a replacement for a stretched chain.

Having taken into account all the advice, and having made sure that it is necessary to shorten the chain, it is important to know the sequence of actions and possible ways replacements.

There are not many of them and they depend on how many links need to be removed and under what conditions the repair will be carried out.

Each link (the cutter and the links connecting them) has two such rivets. If nearby “native” connecting links are damaged, you can use elements from any other similar circuit of any equipment, even automotive equipment. You just need to file the profile, especially at the bottom, where it has a small groove.

The easiest way is to take a long chain, in which several segments can be removed without problems. This way, at least, it becomes possible to use family links. They can be removed using a hacksaw, but it is better to use sandpaper.

Initially, it is necessary to grind off unnecessary rivets, and then cut them off extra area. To do this, you need to pry it with a knife and knock out the rivets from the unnecessary links using a homemade knockout.

When connecting a new chain, you have to make homemade riveting of the links. The rivets themselves can be bought at the store, but if you don’t have them, use steel wire, or better yet, a short bolt with a flat head. Riveting is done on a rigid base (metal workbench or vice). Alternately threading through the elements of future rivets, flare them with a hammer reverse side.

Selection of chain taking into account stretching

There are no special solutions in this regard. You just need to remember about the complex wear and tear on the equipment of the chainsaw itself. You should either change it entirely during prolonged operation, or take care to extend the service life of its main part, that is, the tire and sprocket.

There are no special solutions in this regard. You just need to remember about the complex wear and tear on the equipment of the chainsaw itself. You should either change it entirely during prolonged operation, or take care to extend the service life of its main part, that is, the tire and sprocket.

The operation of the chainsaw will last longer only if it is additionally equipped with several chains. Professionals in particular do not neglect this circumstance and purchase together with the saw additional bus and/or several circuits.

Things to remember: By alternately changing the chains in time and turning the tire over, you can delay the wear of the cutting equipment as much as possible, which means you are less likely to resort to shortening the chainsaw chain.

From this video You will learn how to shorten the chain on a chainsaw:

It is not uncommon for situations when, when installing a shorter tire on a chainsaw, you have to change and. This information will tell you how to shorten the chain on a chainsaw so that the part completely exhausts its service life. In another option, it is possible to fit a long chain to a shorter standard guide bar.

For repairs, unstretched chains with a relatively short lifespan are used, which have received partial damage when they break or the cutting links get into metal inclusions contained in the wood.

Experts advise riveting and repairing a damaged chain with minimal loss of quality using the technical potential of a service workshop.

Despite assurances from manufacturers about problems and difficulties self-repair, a significant part of users prefer to learn techniques for restoring the functionality of saw sets on their own.

The reason for this phenomenon:

- the owner lives at a great distance from service and maintenance points;

- high cost of repair services provided;

- lack of necessary equipment.

Compensating for natural chain wear by shortening is neither advisable nor safe. Operating a saw set with a stretched chain is inevitably accompanied by:

- forced wear of the tire and drive sprocket;

- increased load on the engine;

- increased risk of injury during sawing operations different levels difficulties.

External and internal factors of accelerated wear

The reason why the chain on a chainsaw is stretching intensively may be incorrect choice chain oil or replacement of the recommended material with an oil substitute, malfunction of the lubrication system or inaccurate adjustment of the variable displacement oil pump.

Filling the lubrication system with material of substandard density and viscosity negatively affects the lubrication and cooling efficiency of working surfaces, and the performance of the pump supplying chain oil to the saw set.

Refilling summer oil can create many problems when operating a chainsaw at low air temperatures of -10°C. As a result of an oversight, the oil pump drive may break down, reducing its performance to the level of oil starvation.

Possible causes of spontaneous saw chain breakage

If the chain on a chainsaw breaks, it is necessary to find out the cause of the malfunction and determine the feasibility of repairing the damaged part or installing a new one.

Typical causes of saw chain breakage are unfavorable external factors:

- excessive tension;

- wear of the guide bar or discrepancy between the shanks and the width of the working groove;

- operation of the saw set with large constant loads;

- overheating of the headset due to lack of lubrication;

- the chain does not match the type of tire and the configuration of the drive sprocket crown.

Features of home renovation

Many experienced users prefer to repair chains themselves. The success of the work performed is determined by the presence of special skills and tools, knowledge of the design features of models for various purposes.

In particular, dismantling and assembling wear-resistant analogues does not create difficulties. The carbide compound is applied only to the cutting edges of the saw links. As for connecting elements and rivets, standard metal is used for their production.

With greater or lesser success, you can rivet a chainsaw chain at home, and if you have the right tool, even field conditions. Please note that during subsequent use of a self-repaired headset, special care should be taken. At the first opportunity, it is advisable to have the connection repaired in a hospital.

Post-repair restrictions

The problem is that the hastily repaired part contains one or more “weak links.” In this state, the operating time of the headset under heavy loads is significantly limited, and increased demands are placed on the full operation of the lubrication system.

It is possible to use a restored chain in operating mode, provided that the repair was carried out by an experienced riveter who has a riveting machine and other equipment at his disposal. special equipment.

The initial stage of repair and restoration work

All known methods of shortening a saw chain require criteria for the rejection of damaged cutting and connecting links and a technology-defined sequence of work operations. The cutting and connecting links are mounted with factory rivets, which in all respects comply with current standards.

The use of homemade components is not recommended in any case. Special rivets for chains are extremely rare on sale, so in most cases the problem is solved by installing the necessary parts removed from the dismantled section of the chain.

Sequence of dismantling and subsequent assembly

At home, it is easier to disconnect the chain by cutting off the heads, after which the shortened rivets are easily knocked out with a thin steel rod. The task is simplified by the presence of a release clamp suitable for the pitch of the chain. The rivets removed by such a device can be used without restrictions.

You can independently connect the ends of a shortened chain in a bench vice. The rivets threaded into the chain elements on the reverse side along the circumference are flared with light blows of a medium hammer. The finished connection should not have any play, and a tight fit should not be allowed.

During assembly different types saw chains, it is necessary to observe the dimensional intervals between the cutting links prescribed by the design.

Range of saw chain repair machines

A special machine for riveting chainsaw chains is included in the list of working equipment of specialized workshops. The offered range includes several budget and branded imported models costing from 2000 to 5500 rubles.

Riveting machines are characterized by increased capabilities and a comfortable level of work brands Calm, Husqvarna and Champion.

The cost of universal Shtil NG-7 riveting machines is about 18,000 rubles. Technically advanced devices provide high quality riveted connections, saving working time and material resources.

The cost of a special one varies from 2000 to 6000 rubles

Repair standards and restrictions

Grinders stuck by welding or heated by an abrasive wheel, the connecting elements of the chain are less wear-resistant, which significantly affects their reliability.

- A tight connection of adjacent links is accompanied by additional loads on the engine and kinematics of the chainsaw.

- The lack of a smooth movement of the chain makes it difficult for the headset to enter the cut; the possibility of kickbacks and other traumatic moments cannot be ruled out.

- “Over-tightened” and loose connections of a repaired chain are more susceptible to breaks when sudden change loads

The simplest machine in design for repairing chainsaw chains justifies its cost by being able to completely rivet a damaged chain in a short period of working time and restore its performance to a level of up to 90%.

Chainsaw chains made in China They are essentially copies of European models, so the above repair recommendations are valid for the entire Chinese chain range.

Criteria for self-selection of saw chain

In everyday life, the quality of removable saw equipment from leading European brands is highly valued. Guide bars and chains from the Stihl and Husqvarna brands enjoy unofficial status as reference products.

When purchasing a product, you must make sure that the model meets the design standards of the chainsaw in terms of length, pitch and shank thickness. The entire chain range is divided into five size groups with intervals from 1/4 to ¾ inches.

Small-cube chainsaw models are equipped with products with smaller pitches budget class, chains with increased pitch and thicker shanks - characteristic feature sets of powerful and productive professional chainsaws.

How to eliminate the risks of purchasing a low-quality counterfeit

When purchasing a branded chain on the market, the risks of purchasing a counterfeit Chinese chain cannot be excluded. Task independent choice is complicated by the lack of a reliable way to distinguish a high-quality branded original from a fake, which in terms of working life is an order of magnitude inferior to branded products.

With greater confidence, you can identify Shtilevsky chains by their silver packaging, bright orange logo and the presence of a wear indicator. Cheaper in cost Chinese analogues decorated more modestly, in gray boxes with a yellow trademark.

Without fear, you can buy saw chains that are full of quality and durability in branded stores and licensed sales representative offices of intermediary companies.

Pro recommendations for preparing a new chain for use

Practice has proven the effectiveness of stabilizing the internal structure of the saw chain metal. Sufficiently long heating of the product in an oil bath at a constant temperature of 60-70°C eliminates internal stress and helps restore the metal crystal lattice.

Optimal time heating of the tool steel from which the cutting links are made can vary over 7-10 days or more.

Nuances of long-term storage

If the chainsaw is not going to be used for a long time, it is recommended to remove the bar and chain, thoroughly clean it and treat it with any neutral preservative. The above fully applies to spare headsets.

Regardless of the type of packaging, it is advisable to store dismantled parts in dry rooms with a stable temperature. Subject to these conditions, the formation of condensation moisture and the appearance of pitting corrosion are excluded.

The chain tension on a chainsaw affects not only the normal operation of the unit, but also the safety of the operator working with it. A chainsaw is a very dangerous tool, and a weakened saw chain can lead to dire consequences. In turn, an over-tensioned chain increases the load on the tool. Therefore, before each start-up of the device, you must make sure that this important element has the correct tension.

A quick check of chain tension is very simple: just grab a tooth and pull it up. If the chain is tensioned correctly, the tail will be immersed in the groove of the bar at 1/3 of its height. Exceeding this indicator indicates excessive tension, and a decrease in this indicator indicates weak tension.

Normally, the saw should move freely along the bar, without application special effort. If the movement of an element is difficult, this is a sign of excessive tension.

At strong tension the cutting element of the chainsaw, the tire begins to heat up and wear down, the load on the engine increases, and it quickly wears out. Turn on the unit with loose chain is prohibited, since during sawing it can be pinched and torn, which poses a danger to the user of the unit. The chain can fly off the tire and injure limbs, and it often injures itself and damages the tire. Also, working with a weakened chain element leads to one-sided tire wear, after which the device stops working. smooth cuts, and the saw moves to the side.

Basic chainsaw chain problems

Chainsaw users often encounter problems with saw chain tension. It either weakens spontaneously or stretches and falls off. As a rule, these troubles are caused by unit breakdowns. Therefore, before starting the chain link tensioning procedure, you should check and correct possible reasons, which may lead to adjustment failure.

The reasons that The chain on the chainsaw is stretching, there may be heavy loads or insufficient supply of lubricant to the tire. Because of this, the saw overheats, the metal expands, the size of the saw element increases, and it flies off the tire. The flow of oil may be disrupted if the pump breaks down, the channels become clogged, or the oil hose breaks.

If you have replaced the chain on your chainsaw with a new one, then be prepared for the fact that it will stretch a little during the break-in period. It is only necessary to check the tension in time so that the element does not fly off the tire.

A chain made from low-quality steel is also quickly subject to stretching.

When the driven or driving sprocket wears out, the effectiveness of adhesion to the chain links decreases, as a result of which the saw element flies off. In this case, you will have to unscrew the chain drive and change the sprocket. Also, the saw blade of the unit may fly off due to its stretching or deformation of the tire.

If on your chainsaw the chain weakens, then this malfunction can be caused by a failed tension mechanism.

Tension algorithm

Before tightening the chain on a chainsaw, you must turn off the engine of the unit, or unplug it from the mains if it is an electric saw. Do not adjust or replace the saw element while it is hot. If this is done, the metal will shrink after cooling and the tension will be too great, which can lead to increased load on the engine and deformation of the tire.

Chain tensioner located with right side unit, under the cover, in the place where the brake and clutch are installed, and the tire mount is located. On Husqwarna, Stihl, Poulan and Partner chainsaws, the external tensioner looks like an ordinary bolt.

So, to configure the chain element of the device, you need to perform the following steps.

On a Makita electric saw The tension regulator is designed in such a way that it can be turned without the use of any tools. By rotating it clockwise, you will tighten the chain; if you rotate the adjuster in the opposite direction, the tension of the chain element will weaken.

Replacing the saw element of a chainsaw

If you need to replace the chain on your chainsaw, follow these steps.

- Remove the cover covering the sprocket. To do this, most often you need to unscrew the fastening nuts.

- After unscrewing the fasteners, remove the cover covering the sprocket coupling.

- Hold the bar with your hand and push it towards the sprocket to loosen the chain.

- Remove the chain element from the drive sprocket.

- Now you need to install the chain on the chainsaw. Take the new saw element and place it on the drive sprocket first.

- Then you need to put the chain on the bar, placing the element in its groove along the entire perimeter. It is important that the links fit correctly onto the driven sprocket located at the top of the tire. When installing, pay attention to direction of cutting links. They should be directed in the direction opposite to the unit, on the top of the tire.

- Feed the bar in the opposite direction to the engine to tighten the chain a little.

- After laying the saw element, before putting the cover in place, it is necessary to align the screw through which the tension is adjusted with the adjuster located behind the bar. Only after this can you put on the cover and lightly tighten the nuts. Next, insert a screwdriver into the adjusting screw and apply final tension. How to properly tension the chain was described above.

- Lift the tire slightly and tighten the nuts to secure it. It is important not to overdo it and break the thread.

Is it possible to shorten the chain yourself?

In the case when the chainsaw chain has stretched so much that it is no longer tensioned, it becomes necessary to reduce its length.

This also has to be done if the existing bar is shorter than the chain, and it is not possible to select a suitable saw element.

It is possible increase the saw element, adding new links that can be purchased separately or removed from a similar one. In stores you can see a chainsaw chain wound on coils, which is sold by the meter. In general, repairing chainsaw chains can be done at home, since finding all the components for it is not difficult.

How to remove a rivet

To change chain elements or shorten it, you will need to separate the links in the following way. Secure the chain element in a vice and grind off the rivets, namely, their protruding parts. To do this, you can use a file or needle file. Make sure that the side parts of the link are not ground down.

Using a beard (what it looks like is shown in the photo below), knock out the rivet.

There is another option for disconnecting the links. This does not require grinding off the rivet heads. Place the link, namely its rivet, over any hole in the metal or over the slightly set jaws of the vice. Next, you should place a tool bit on the head of the rivet and hit it several times with a hammer.

Continue to knock out both rivets one at a time, as they are firmly secured by the opposite part of the link. Gradually the rivets will start to come out of the top of the link and it will come apart.

Advantage this method The point is that the rivets can be reused because they do not wear off.

How to connect the links

First, you need to purchase links from a specialized store that match the type of chain you have. You will have to do this if you ground off the rivets when disassembling the chain element. Then you will need correct link assembly taking into account the arrows indicated on it. Place the assembled element on the anvil and rivet the rivets with gentle blows of a hammer.

Don't be afraid to rivet, as the rivet has a thickening in the central part that serves as a limiter.

Some craftsmen advise connecting the links by welding. This method is suitable if the rivets were ground down with a file. But first you need to experiment on some piece of hardware to choose the appropriate welding mode.

Welding must be carried out with a short and thin electrode. The rivet is welded to the side of the link, and excess metal is removed with a file. The only drawback of this method is overheating of the metal from which the circuit elements are made. As mentioned above, due to overheating, the wear resistance of the links may decrease.

The chain is the main functional part of the chainsaw. The quality and speed of cutting directly depends on its condition. Additionally, a faulty saw chain is a serious safety hazard to the tool operator. Therefore, at the slightest sign of dullness, sagging, lack of lubrication, etc., you should immediately begin repairing the tool. However, almost any of these problems can be eliminated by timely maintenance of the chainsaw. And to do this, you need to understand the design features of the saw chain, as well as the rules for caring for it.

When is chainsaw chain repair necessary?

The condition of the saw chain affects not only the convenience and quality of cutting, but also fuel consumption and. In addition, the operation of a faulty chain can lead to both complete failure of the tool components and injury. Therefore, before starting work, you must check the condition of the chainsaw, the presence of oil and combustible mixture, as well as the integrity of the body and the functionality of the controls.

The service life of a chain depends on many factors - the materials from which it is made, operating conditions, operator's work style, etc. During normal operation, a professional chainsaw is serviced every day. Concerning home tool, it is not used as intensively. But you should still prepare for cutting by drying and cleaning the material from dirt and foreign objects.

The chain of a household chainsaw must be repaired immediately if signs such as:

- slowdown and difficulty cutting;

- beating or increased vibration;

- chip heterogeneity;

- deposits on the cutting line and chips;

- characteristic smell of burnt wood or overheated metal;

- dust emission when cutting, etc.

If you have necessary tool, knowledge and skill, it is not at all necessary to contact the service center- stretching, sharpening, etc. can be done independently. Direct visual inspection of the saw chain allows you to verify the presence of malfunctions, as well as identify their extent and determine suitable way elimination.

The chainsaw loves to work, so it should not be left idle for long periods of time. If you are not going to use the tool in the near future, you need to properly prepare it for storage.

DIY chainsaw repair: lubrication system

As a rule, chainsaws are used in conditions that are far from clean. And it is the saw chain that is subjected to the highest loads. Its premature wear is prevented by the tool, which reduces the destructive effect of heat and friction. This not only increases the working life of the chainsaw’s structural components, but also prevents chain stretching. Therefore, control over the lubrication process must be carried out constantly.

Chainsaws are equipped with an oil pump, which takes lubricant from the tank and supplies it to the chain. Its design includes special links - shanks. As they pass the tire sprocket, they capture oil and distribute it along the entire length of the chain. Bottom part shanks are made in the form of a hook. This allows you to reduce consumption and loss of lubricant. For additional retention of the latter, the shanks are equipped with additional channels and holes. Other links of the saw chain also participate in the distribution of lubricant, on which specially shaped recesses are made for this purpose.

It is not difficult to check the quality of the chainsaw lubrication system. When the saw chain accelerates, microscopic oil particles form a mark on the surface of the material being processed. The absence of this indicates that the chain is not receiving lubricant. And vice versa, if grease literally drips from it when the engine is turned off, this indicates the need to clean the tire groove, structural holes and channels of the chain links and adjust.

Before purchasing and installing a new chain set, you should make sure that the chainsaw's lubrication system can handle it. To improve the lubrication process, you can use modern plant-polymer based oils.

Chain Brake Troubleshooting

The inertial chain brake is designed to instantly stop the movement when the chain is jammed and back kick. The latter occurs when the end or top part tires of the processed material. At the moment of a sharp throw of the tire, the brake stops the movement of the chain without stopping the engine. Therefore, after it is triggered, it is necessary to turn off the motor and then unlock it.

When the brake is applied, the tire drive sprocket cup is blocked. In this case, the engine power is enough to turn the clutch. As a result, its cams will rub against the cup, and the mechanism itself will heat up. As a result, plastic elements may melt - oil pump drive, clutch cover, etc. If you continue to work with the brake on, a characteristic smoke and smell will appear, and the saw itself will most likely have to be repaired.

A similar situation can occur when the chain becomes pinched in the material being processed if the operator tries to free it by increasing engine speed.

Chainsaw manufacturers recommend checking the inertia brake every time you start the engine. If it is faulty, working with the tool becomes unsafe, and its service life is reduced, which will lead to unexpected financial expenses in the near future.

Adjusting saw chain tension

A professional feller will never start working with a chainsaw until he has checked the chain tension. If it is weak, the headset will dangle when moving, jump off the tire and may well burst. Excessive tension also does not bode well - increased load on the engine and rapid wear structural elements critically reduce the tool.

In most models, tension on the saw chain secures the bar. This means that if it is insufficient or excessive, the tire will have increased play, or its sprocket will be pinched and will not be able to move the headset.

The saw chain tensioning procedure is performed according to the following algorithm:

- Checking the chain movement.

To do this, approximately in the middle of the tire in its upper part, the chain is taken by the tooth and pulled vertically. At optimal tension, about a third of the shank will remain in the groove of the bar, and the chain itself rotates freely by hand. If not, it means it is overtightened or loose.

- Security control.

Before you begin the repair, you need to make sure that the chainsaw is turned off and its accidental starting is completely excluded.

- Assessing the degree of tension.

To do this, you need to rotate the chain by hand along the working stroke line. If the headset is loose, you will notice sagging at the bottom of the tire.

- Checking the tensioner.

This unit is located inside the tire retaining cover, which is located near the brake clutch. You should loosen the locking nuts and turn the tensioner () until normal tension is achieved while maintaining smooth movement of the chain and the necessary hinge play.

Do not change or adjust the chain while it is hot. When cooling, the metal contracts, so a headset adjusted in this way can deform the tire or damage the engine.

This is perhaps the most difficult task when servicing saw chains. To perform sharpening you will need:

- files (round and flat);

- mandrel;

- caliber.

The chain is sharpened directly on the saw bar. To do this, taking into account the chamfer sharpening angle (10-30 o), a mandrel is placed on the cutting edge of the tooth. The main thing when performing the procedure is to observe this angle. In this case, the tire itself must be installed perpendicular to the tire so that a slight protrusion above the tooth is maintained. Sharpening is performed using strictly translational movements. When finishing work with one cutter, the chain rotates to provide sufficient space for work with the next one.

After processing the cutters, you can begin editing the stops. If they protrude, the chain will “iron” the material, but if the position is too deep, the saw will get stuck in it. The limiters are adjusted using a gauge that is installed on the cutting edge. Its end plate with a slot must be at the level of the limiter, otherwise the latter will be undermined.

To sharpen saw chains, it is not always convenient to use the kits supplied with the tool or improvised means. If the cutters are thoroughly dull, it is reasonable to use a special one - it can be either manual or electric.

When sharpening cutters and straightening stops, an equal number of file movements should be performed with identical applied force. The teeth of the chain must be the same, otherwise its movement will be uneven, and the chain itself may crack or burst.

Saw chain maintenance is one of the most important tasks facing a tool operator. The efficiency and safety of work directly depends on how well the headset is installed and sharpened. You can achieve a significant increase in tool life by following the algorithms recommended by chainsaw manufacturers for tensioning and sharpening the chain, as well as by maintaining the brake and lubrication systems in good condition.

Sharpening a saw chain, video