ABB series s. ABB modular equipment (automatic machines, RCDs): What is needed for what? (Updated, Video)

ABB Concern (ABB, ABB) offers a wide range of modular devices of standard sizes designed to protect electrical equipment from short circuits and overloads. Equipment series have different response characteristics:

● B - devices of this class are suitable for long cable lines with grounding of types TN-C, TN-S, TN-C-S and IT;

● C - designed for inductive and resistive loads characterized by low performance pulse current;

● D - provide effective protection of loads with high values of starting pulse current (for example, discharge lamps and low-voltage transformers);

● K - circuit breakers, equipped with high-precision magnetic releases and incorporating a sensitive thermoelement, which makes them optimal solution for use in networks with high pulse current;

● Z - primarily used to protect control circuits from small, long-term overloads.

Low-voltage circuit breakers S-series

The Compact Home line is presented inexpensive models SH200L, intended for use in the housing and communal services sector. Their closest analogue is the Legrand RX3 automatic machines. In the catalog of the Electrodus online store you can purchase devices of category C with a breaking capacity of 4.5 kA. Available in 1P, 2P, 3P, 4P options for current ratings from 6 to 40 amps. The System pro M compact series (includes the S200, S200M, S200P lines) has found application in the field of residential and commercial construction. Basic specifications equipment are given in the table:ABB S280, S290 and S800 circuit breakers are designed for industrial applications. S280 is currently the only industry solution with a pole width of 17.5 mm. They are capable of withstanding 80/100A current and have tripping characteristics B and C. For networks with high voltage(up to 440 volts) modification S280UC is provided. More expensive ABB S290 circuit breakers are designed for installation in reception and distribution cabinets designed for modular devices with a rated current of up to 125A. The S800 range includes models C, D and K. distinctive feature became the double contact breaking technology, the use of which made it possible to increase the response speed to 1.5–2 milliseconds. Despite their compactness, these devices are characterized by a breaking capacity of up to 50 kA. Due to their high selectivity, they are often used in conjunction with Schneider Compact NSX introductory machines and their analogues.

Molded case power breakers SACE Tmax

The Tmax series has been specifically designed to protect low voltage (up to 690V) and high voltage (up to 1150V) AC and DC distribution networks up to 3200A. All products and compatible accessories fully comply with IEC 60947-2 and GOST-R 50030.2 standards, and also meet the requirements set forth by the Russian Maritime Register.ABB Tmax circuit breakers are offered in three- and four-pole versions; models can be stationary, withdrawable or plug-in.

Among the advantages of the line are:

● Compact dimensions compared to other solutions with similar characteristics;

● Elimination of device overheating, reduction of peak currents and significant limitation of specific end-to-end energy due to high speed contact openings and improved arc chutes;

● Availability of built-in means of measuring voltage, current, power and other parameters of the power network;

● Easy integration into an existing telemetry system thanks to support for a wide range of industrial communication protocols (ProfiBus, ModBus, DeviceNet, CANOpen).

To buy an ABB automatic machine and other electrical products, place an order in the Electrodus online store. We are official distributor brand, therefore the catalog presents only original products at prices recommended by the manufacturer.

Hi all! I was here on Thursday at a party from ETM in training center ABB. The greasy faces of the salespeople from ETM did not please me, and I gave up on them. But it was more fun and enjoyable with the ABB people! And while the ETM people were telling everyone about their iPro, in which they had been unable to upload a list of prices for several years, we exchanged opinions on how this whole party went. And the ABB people shared one thing with me. They say: “Wow! It turns out that people don’t know ANYTHING about our module AT ALL! Not what episodes go where, and even WHAT EVEN HAPPENES THERE!”

Addition. The post has been updated. I clarified the information on E200 switches and DSN201 electronic differentials. I also took a video!

Well, since I personally observed the almost complete silence of the hall for all sorts of simple questions, such as “why an impulse relay saves energy,” then I came up with the idea of doing a short summary post so that everyone has everything at their fingertips! The information here will be diluted with my comments and my professional and practical opinion. Information is current as of 2017. If ABB changes something, I will later supplement this post. Let's go find out!

Let me add one more note. Most of the modules (some pulse and other relays are an exception) from ABB have a standard width of 17.5 mm (according to the DIN standard). And other manufacturers round this standard to 18 mm. Therefore, combs from other manufacturers are not required to fit the ABB module. And also, if the shield from ABB is assembled on ABB, then there will be gaps in it along the edges of the slots for machine guns: this is a concern for those whose modules are 18 mm wide.

The first thing you need to understand from ABB is that their modules are divided into two large segments - simplified for home use and industrial. In the designation they differ from each other by the letter H — Home, and are called Compact Home And System Pro M. Here's how they differ technically.

Compact Series H ome:

- It is important for our country: most often they are counterfeited because it is cheaper, and there is a small number of items, and it is profitable to counterfeit them.

- The machines are certified ONLY for household use(apartments, small offices). For industry (workshops, factories) these machines CANNOT be used. They did not pass the necessary tests for this. Therefore, those who buy the Home series using the factory’s shield can be called enemies =)

- It is simplified in terms of the contacts to which the wires are connected: the contacts accept only one wire, there is no separate groove for the comb (connecting bar), the screw slots are weak.

- A small range of denominations. For example, there are no 10 mA RCDs, no selective RCDs (which are installed at the entrance to the house or to the floor panel in the apartment).

- Some things, for example the DSH941R automatic rifles, are very weak in terms of housing and do not withstand our harsh reality well.

System Pro M Series:

- Most often they are not faked, because in this series big choice types and denominations, and it is not profitable to counterfeit all of them.

- It has passed all the tests and certificates that are needed in order to use these machines in industrial applications and all sorts of serious objects.

- More powerful and brutal contacts: powerful screws, deep slots on the screws, there is a second contact for a comb or a second wire (you can clamp two wires under one screw as standard). It is much more convenient to mount the shield on them. At the same time, all elements of the series (automatic devices, RCDs, difavtomats, circuit breakers, SPDs) are made compatible in terms of contacts, so they can all be crammed into a panel under one common comb, if this is suddenly needed.

- There are all sorts of accessories - additional contacts, releases (to turn off the machine remotely).

- Large range of types and denominations. For example, there are automatic devices and RCDs of type “A” and 10 mA. There are shutdown category B differentials and a bunch of other interesting things.

In our slang language, we usually divide everything into with and without “H”, and call it either a simplified or a full-fledged (industrial) series. I chose a full-fledged series for myself because of the double contacts and powerful slots of the screws: in this case, the combs go back into the depth of the panel and do not interfere with the wires, and the powerful slots allow me to assemble the panels with a screwdriver and pull all the connections very strongly and powerfully (which for us important, because usually the shield is put up and forgotten and no one watches it later). And at the same time, this series is certified for industry, so you don’t have to worry about it and put it EVERYWHERE! =)

And now I want to systematize everything briefly and in detail, with links to my own posts.

Let me remind you that ABB's old series of modules have been discontinued for a LONG time (). Therefore, if you see somewhere old series of automatic machines (such as S23x, S24x, S26x), UZOs (F46x with a rectangular protrusion), difavtomats (DS94x - without “H” and “R”) or switches (E20x) - then it’s better to tear them down in the trash, especially RCDs and automatic machines. They became obsolete a long time ago! And if you see mention of these series in new projects, kick the designers in the kidneys with your boots, because this will prove that instead of your project they handed you someone else’s old template shaggy years!

2. Automatic machines and their series (SH200L, S200, S800, S750DR).

First, let's go over the slot machines. What you need to remember and know:

- The machine contains two types of releases (those things that turn it off): thermal and electromagnetic. The electromagnetic one is triggered by short circuits, and it refers to the letters B, C, D on the machine. The thermal release operates on all machines in the same way with multiples of 1.13 and 1.45 nominal and is designed to disconnect the line if too much load is placed on it. About these coefficients.

- Any machine is designed in such a way that it turns off in any way, even if its lever is held with your hands or wrapped with wire. Therefore, making a multi-pole circuit breaker yourself by connecting the levers from the outside will not work - it will not work (one lever, when turned off, will not turn off the neighboring ones)! ABB industrial series machines have a window on the case that shows the state of the contacts (not the lever!), so that you can see whether they are on or off.

- A machine rated at 16A will NEVER turn off at a current of 16A! Therefore, you need to choose them wisely and not right next to each other. Usually, a machine of no more than 10A is installed on a 1.5 square cable, and no more than 16A on a 2.5 square cable.

- The letters “B”, “C”, “D” indicate the magnitude of the short circuit current (sensitivity) at which the machine will be cut off. B circuit breakers are more sensitive than C circuit breakers and are convenient to use on old wiring, where the magnitude of the current during a short circuit may be so low that a category C circuit breaker may not work at all. By default I put them everywhere.

- Selectivity is a whole science that allows you to calculate for a specific line (substation, house, apartment) the moments when, during a short circuit, only the circuit breaker on the outgoing line will operate, but the input circuit breaker will not turn off. About her . You will NEVER get selectivity between a regular module. The fact that someone’s 16A circuit breaker turned off when it closed, but didn’t have a 50A input one, is luck, not science. In order to maintain selectivity, you need to select the necessary machines from catalogs, and for small denominations use a series S750 DR.

- The machine always protects the CABLE and FIXED WIRING (up to sockets, lamps and equipment). Therefore, there is no need to slander on the topic “But how come I have a weak charger in the socket or thin wire to the floor lamp will they be protected? — we work with fixed wiring and our task is to save the cables. Protection is selected according to the weakest section of the network. That is, if you laid a line to the light + sockets with one cable, then you need to choose protection along the light line, and not along the sockets. And such savings will backfire: the power for such a line will be limited to 2.2 kW (10A).

- The machines do not have an “input” or “output” and you can supply and remove power from them as you like. Either bottom up or top down. It would be better if everything within one shield is of the same standard: either everything is below, or everything is above. In our country, it has historically been customary to serve power from above, and this is how I assemble my shields. In Europe, it is customary to serve food from below.

- Inside the shield, it is convenient to connect adjacent machines with special buses, which everyone calls “Combs” in the jargon. IMPORTANT! For different series of machines (Home and Industrial) ABB uses DIFFERENT combs! They are also designated with or without the letter H. If you use the wrong combs or combs from other manufacturers, the panels will be assembled crookedly.

The same combs are suitable for connecting RCDs and automatic devices. When I write about RCDs and differentials, I will tell you which models of combs fit where. You can read quite a lot about combs:- - about what combs there are and how to use them.

- for Home-series and regular.

- — how to conveniently cut them without a hacksaw and other dirty nonsense.

Probably everything I remembered about machine guns. Now let’s go over the series of ABB machines - which ones can be ordered and which ones are available.

Here are the series of machines ABB has. Everywhere in them, the last digit of the number indicates the number of poles. For example, xx1 is single-pole, xx3 is three-pole, and so on (S801, S202, S753 DR). And the series of machines is indicated in general form: S200, S800, S750 DR and so on.

- SH200- home series. It does not come with any accessories or bells and whistles (disconnectors, signal contacts) and comes with its own combs, which are also designated with “H”: PS H x/xx. There is also no contact status indicator (green-red flag). The contacts here are single and their slots are a little weak. The contacts themselves are made in the form of a U-shaped bracket that presses the wire. These contacts are very popular with gopniks, who love to shove five wires into one machine - this form of contact presses the wires against each other, and they do not fall out. We can say that these contacts are specially created for shield-wielding gopniks.

Initially, this series was only rated at 4.5 kA and was always designated as SH200L, where the letter “L” means exactly those 4.5 kA. Now the series has been further developed and there are SH200 automatic machines without “L” for 6 kA. But everything else (clamps, accessories) is the same. And now category B machines have appeared in the SH200 series.

Let me remind you that this series is often counterfeited, and you need to buy it from a trusted place and carefully use PSH combs, not PS. I had a couple of shields when I used this series. , and here . - S200. My favorite series because of the clips. This is an industrial series of circuit breakers, the breaking capacity of which starts from 6 kA. These machines are more expensive than the SH200, so they are less likely to be counterfeited. There are series machines S200P with increased breaking capacity (tens of kA), there are circuit breakers for D.C., a bunch of goodies (signal contacts, releases). Of course, there are all categories of shutdown, including such exotic ones as Z or K.

And most importantly, these machines have double terminals! Each terminal consists of two holes: one for the wire, the second, lower, for the comb. This allows you to twist two wires into the machine at once, if you suddenly need it, and in normal mode. Also, the terminals have a different design: here a powerful rotating washer presses on the wire, which will flatten it and clean it if the wire was crooked and with oxides. And there is also a very deep slot that does not break off when tightened with something powerful.

On machines of this series, I collect all my shields and work only with this series or with more serious ones. - S200S. This is a version of the S200 machines, which have a spring clip on one side. Such machines are designed to make connecting switchboards even more convenient: just plug in the wires and you’re done (especially when the switchboard also has spring bars). These machines are not particularly popular with us, because they are custom-made and because their spring output is made according to the German standard: at the top, and not at the bottom like ours.

- S800- this series is interesting because it has high breaking capacities (tens of kA), but at the same time it is made in such a way that it can be installed in ordinary switchboards on a DIN rail, which is why it differs advantageously from. The S800 series machines protrude outwards more strongly (they stick out from the panel higher than a regular module), so they will not fit only into those panels where the distance from the machine levers to the door is too small. If we talk about ABB shields, then IP65 will most likely be installed in Mistral, and more severe in AT/U for sure, but I haven’t tested it with Mistral 41.

These machines also have partial selectivity with a conventional module, so in some places they can be used as input. Well, their clamps accept large cross-section cables - up to 50 (I’m writing from memory) squares. - S750 DR is a special series of selective automatic machines. They are expensive (15-20 thousand), but are designed in such a way as to ensure complete selectivity in the event of a short circuit with a conventional module. That is, if you buy an S752 DR with 16A input and buy a regular SH..S201 with 16A and stick a nail in after the regular machine, only the regular machine will be switched off. And if you insert a nail after the S750 DR (before the usual machine according to the scheme), then the S750 DR will be switched off.

Therefore, if you really need selectivity at the input, where the machine has a small rating (usually 15 kW for three phases, where they install a 25A machine), then the S750 DR is your choice. The only thing is that you need to make sure that it is not stolen from the shield on the pole.

Most machines (S/SH200 series for sure) are made in Germany at the Stotz-Kontakt plant. Here is a video on the machines, filmed at your request:

3. RCDs and their series (FH200, F200).

Now let's deal with the RCD. And we immediately deal with the name, because RCD is a slang name that has stuck with us. Stands for U construction Z protective ABOUT disconnection, but does not make any sense. Does the fuse cut off the line for protection? So he is an RCD. Does the machine disconnect the line? That means he too is an RCD. Does the voltage relay cut off the line protectively? This means that it is also an RCD. Correctly the RCD is called “ IN switch D differential T oka (VDT)”, because it reacts to current leakages, but in our country it’s customary that everyone calls it RCD. About. Briefly we can say this:

- The RCD reacts to the difference in currents when more has gone out than has returned (or vice versa: more has come in than has gone out). Where does this difference come from? I don’t care about the RCD. It can be taken either because the plasterers cut through the cable insulation with a spatula, and part of the current goes into the wet wall (and when it dries, everything is fine), or because a drunk dude after a bath (drunk and/or a wet body conducts current better) grabbed the broken kettle in the kitchen. This current difference is called “Leakage”. If the value of this leakage is greater than a certain value to which the RCD is set, then it turns off the line.

- IMPORTANT! An RCD will not save you and your children if they stick two nails into a socket and grab them different hands! Then the current will flow through the human body, and there will be no leakage for the RCD: as much as it went into the person, so much will return. And the human automation will consider it some kind of charger for gadgets.

- Based on the leakage current, RCDs are divided into those that protect people: 30 or 10 mA, and into introductory, so-called “fire safety” ones - 100 or 300 mA (we usually don’t need more). A fire protection RCD is usually installed before the input cable or, if we are talking about a country house, then before the cables that go from the main switchboard to neighboring buildings. Its task is to cut down the line if the line insulation has become poor. For example, if the insulation melts due to a fire, gets frayed, or is eaten by mice/moles. It’s still a long way from closing for the input circuit breaker to work, but there’s already a leak. This is where such an RCD will turn everything off for us.

- There are special selective RCDs with the letter “S” in the designation. It’s good to use them as fire protection devices, because non-selective RCDs for the same 100 or 300 mA do not always provide selectivity with conventional RCDs for 30 or 10 mA. I had such an experience when, with an unwavering hand, I closed N and PE in the socket with the words: “Now I’ll show you why an introductory RCD is needed and that it will not work.” It worked. And since then I have only installed selective RCDs at the input.

- IMPORTANT! The RCD does not have overload protection inside (if a current flows through it greater than that for which its contacts are designed). Therefore, panels with RCDs must be assembled so that the current rating through the RCD does not exceed its rating. When the PUE was written, RCDs were something like flying saucers, and therefore in the PUE for RCD protection it is written very abstractly and formally: “it is prohibited... to be used... in circuits without circuit breakers.” And because of this phrase, rumors are still going on all over the Internet, as a result of which people are collecting shields so that in front of each RCD they also place a personal machine to protect this RCD. Or puts the RCD at a higher nominal value.

There is no need to do this. The information is valid only for ABB. For ABB narrow protection devices, it will be enough if they are covered with an introductory shield machine. For example, if we have an input circuit breaker on the switchboard set to 40A, then we can install all the RCDs in the switchboard at 40A and not worry about anything. But if the input circuit breaker has a nominal value greater than the rating of the RCD - for example, let it be 50A - then it is necessary to design the shield so that the RCD is covered by the outgoing circuit breakers: so that the sum of their ratings does not exceed the rating of the RCD.

That is, if we have a 40A RCD and a 40A input circuit breaker, then under this RCD there can be at least ten circuit breakers according to the scheme. And if we have a 50A input circuit breaker, and a 40A RCD, then after it, according to the diagram, there should be circuit breakers with a total of no more than 40A. For example, 4 x 10A or 2 x 16. Or 16+16+6. - There are AC and A type RCDs. AC type RCDs only react to leaks alternating current(the cable insulation was damaged, the heater was pierced into the housing). If some of the diodes in some thyristor dimmer or drive die and a pulsating current flows into the line, then the AC will not turn off. Only RCDs of type “A” react to such currents. Now more and more more technology Comes with switching power supplies. It's been a long time since I've seen regular large transformers in household appliances. Therefore, it was unspokenly decided that on all lines, except for those where there are clearly only ordinary heaters (these are usually only warm floors), I install type “A” RCDs. And even to the light, because now many people use LED lamps with the same switching power supplies/drivers.

- What lines should be added under the differential protection? If we do it not formally, according to papers, but for the people - then EVERYTHING except the low-voltage shield, video surveillance and burglar alarm. Especially for security alarms: differential protection for them is prohibited by law (except for fire protection RCDs), so that false alarms do not turn off the security system.

Why all the lines? And because the differential protection protects not only the person, but also the wiring. For example, if the air conditioner was connected to you badly, and there is an RCD on this line, you will find out about it at the first rain. And without an RCD, you won’t know, and you’ll heat water in the cable or terminals of this condo and potentially kill some pigeons =). That is, over time, after tens of years, the insulation in the cable will begin to deteriorate. If there is differential protection on the line, then leaks will occur, which will trigger ordinary 30 or 10 mA RCDs. This will disconnect the line before a short circuit occurs. That is, the principle is the same as with a fire protection RCD at the input. - The number of RCDs in the shield is usually chosen based on human logic - to make sure that if one RCD is completely turned off, then at least part of the lights or sockets will work. People design shields in different ways. Someone puts several RCDs in the shield (“UZO 1″, RCD 2” and so on) and throws a machine gun on them randomly (Bathroom light, Warm floor corridor, room sockets, washing machine). Someone (me) divides UZOshki by type of load: light, room sockets, kitchen sockets, kitchen appliances, climate, and so on. In my method, it is more convenient to assemble the shield, because all the machines in it will be next to each other: the light with the light, the sockets with the sockets. This means you can use combs! =)

- If L-N is not clearly indicated on the RCD, then they can be on either side. If you want L-N, if you want N-L. At ABB, all RCDs are strictly electromechanical, so they don’t care where the phase and zero are, and they don’t care which side the power is supplied from (top or bottom). Zero is clearly indicated only on three-phase RCDs, because there it is needed for the “Test” button to work.

ABB has two series of UZOs: home and full-fledged, like with automatic machines. I’ll write about them, but first I’ll make one important note: the ABB home and full-fledged series UZOs have all the same double contacts! Therefore, combs for ABB RCDs are always needed PS2/xx, regardless of the series of RCDs. And one moment. Where I have only two circuit breakers in my panels after the RCD, I don’t install a zero busbar: the RCD clamp is double, isn’t it? This means you can screw both zeros into the RCD at once and not create any more entities!

- FH200. Black lever, yellow DIN rail latch. Household series. Ratings - 30 mA, and 25, 40, 63A. There are no selective RCDs or type A RCDs. There is only AC. Again, this series is often counterfeited due to cost.

- F200. Blue lever, black DIN rail latch. A full series of UZOs. You can find RCDs with contact currents up to hundreds of amperes, for leakage currents up to an ampere (!!) and with a bunch of chips and types. There is type AC, A and even type B to protect against leakage from frequency generators. There are also AR-P type RCDs that slightly filter leakage current pulses so that they do not trigger falsely from any switching surges through the network. I have never come across cases where AP-R will be needed, and thank all the gods =)

Again, due to the fact that in this series there is type “A” and the ratings of the UZOs I need, I work only with this series of UZOs.

All RCDs are manufactured at the ABB plant in Italy.

4. Automats and their series (DSH941R, DS201/202C, DSN203NC, DSN201).

A difavtomat is an RCD and a machine for one line in one housing. Previously, when these devices were just appearing, it was very difficult to fit both mechanisms into one case so that it occupied two DIN modules, so most automatic machines were electronic and unreliable. Therefore, people have the opinion that “Difavtomat is some kind of complex, expensive and quickly breaking crap.” Now the world has changed, and a difavtomat is a fairly reliable and rugged design that does not contain electronics and is completely electromechanical. Here's an example of how the best differentials from ABB are designed - .

Since a difavtomat is an automatic machine + RCD in one housing, all the characteristics and application features (breaking capacity, leakage current, amperage, type of leakage current A/AC) can be found in the previous two paragraphs. The only thing that differs here is that automatic machines do not need to be additionally protected by anything (like an RCD) - since there is a machine inside it, it protects itself.

What is the profit and benefit of difautomatic machines? They are expensive, but where is it needed and how will it pay off? Here's a look at what features and ease of use they have:

- It protects only one line, but the whole line: from overload, and from short circuits, and from current leaks. As a result, the lines do not affect each other in the shield. If our RCD is switched off in a regular panel, then we will lose several machines at once, which according to the diagram were located under this RCD. And if we have a shield on difavtomats, then only one difavtomat per damaged line will turn off, and everything else will work.

This may be important for country houses(or offices, production), when street sockets should not turn off the street lights or boiler room pumps. - Contains all protection. Therefore, if we have some kind of input for 100A, then we can make it and immediately distribute power from it to 16A differentials.

- VERY, VERY, VERY convenient to assemble three-phase panels! Because in this case we need to do the same thing that I already wrote about: install a cross-module and supply power to the diffs. The zero of all differentials is connected by a common comb, and the phase comes from the required buses. Therefore, if you need to switch something by phase, then just move the wire in the cross-module from one bus to another. This concept is outlined. If you assemble a three-phase shield using RCDs and automatic machines, then assembling it will be more difficult. I have developed one, but it got out - it requires a VERY LARGE SHIELD. And if the shield contains several types of food (like for example), then it will be hellishly difficult to make it except on diffs!

Some people here are swearing on the topic “Yes, the differentials are crap, you won’t understand why the line was cut off - due to a leak or due to the machine.” So, ABB differentials (except electronic ones) have a blue flag, which indicates that the differential has been triggered by a leak. If the differential switched off with this flag, then the built-in RCD worked, and if without the flag, then it was done using the built-in automatic circuit breaker or simply turned it off manually.

Here are the series of automatic machines ABB currently has:

- DSH941R. This was the very first series of diffs, which was previously called DS941 and it was so widespread that it was counterfeited by everyone and everything. Around 2014 series DS941 rebranded to DSH941R, therefore, diffs with the old marking are officially NO LONGER SUPPLIED (and with the new one there are also many counterfeits, both with automatic rifles and Narrow Home-series! I hate this series of diffs, because it is very inconvenient, flimsy, VERY POORLY TOLERATES DUST and has completely inconvenient contacts Somehow I had to, and there I described all the features of this series.

These differentials have two clamps located diagonally. They require special combs, models BS9/12 and BS9/12NA (blue), which still don’t fit well and do not allow you to insert the power wire and comb into one terminal of the diff - you need to buy special Feed power adapters. Of the ratings - only AC, only at 30 mA and a number at the level of 6, 10, 16, 20, 25, 32, 40A.

As soon as ABB had new diffs of the DS201/202C series, I immediately abandoned the DSH941R and stopped using them. If possible, I advise you to abandon these differentials. The ABB people know that I swear at them, and even at this ETM meeting they also joked when we were assembling shields there - they say, this is... don’t swear about diffs! Well, here we are! We had a good laugh, in general. I mentioned these diffs, and... - DS201/DS201L/DS202C. This series of diffs - new development ABB, which has long gone to the masses. Now, due to the rise in price, it costs 5-6 thousand, but for this money we get a professional device! Firstly, it has the same double clamps as all components in the series System Pro M. That is, all the combs that are used for the module fit here without any problems. And I use this in three-phase switchboards. Where I don’t need differential protection, I install not one-pole, but two-pole circuit breakers. Their contacts coincide with the contacts of the differentials, so their zero is connected by one comb, and I assemble three-phase shields without a single zero bus.

Secondly, here you have a complete mincemeat for all tastes. Ratings from 6 to 40A, shutdown categories of the built-in circuit breaker B (!) and C, shutdown categories of the built-in RCD A and AC, AP-R, leakage currents of 30 and 10 mA, and even 100 and 300! Moreover, in order not to multiply the essence, 10 mA differentials are produced only in shutdown category “A”: if you are going to produce a differential, then it will be a competent one.

Thirdly, the body here is also well thought out. It's not flimsy or made in layers like the DSH941R was, but consists of a bottom with filling and a lid. Even if you break the lid or lever, it will still work! These differentials occupy 2 modules.

Well, in this series there is a complete set of disconnecting capabilities and poles. It's probably better to show it like this:- DS201L- 1P+N (there is no machine at zero - this is normal for differentials) at 4.5 kA. So it’s better to take at least these diffs instead of DSH941R!

- DS201(I use it) again 1P+N, but at 6 kA.

- DS201M— 1P+N at 10 kA!

- DS202C- two-pole version (there is also a release at zero) for 6 kA or DS202C M at 10 kA.

- DSN203NC. This is a three-phase version of the DS201/202C differentials, which occupies four DIN modules. The development is new, the ratings and capabilities are approximately the same as those of single-phase differentials.

- DSN201. This is an exception from the entire ABB line. Electronic (!!) automatic machines for one module! Since they are electronic, they are afraid of increased voltage! The maximum operating voltage for them is about 260 volts. If the voltage is higher, they may die (although they have protection against increased voltage). Therefore, they don’t really bring them to us, but you can order them, for example, if you are saving a shield in the style of “we have 30 cables, but we bought a shield for 36 modules and there are three phases, but everything is already in the tile and cannot be pulled out” ( I will have exactly this one order). Available for AC at 30 mA and for low currents. If possible, it is better to avoid them and collect all the shields on electromechanical difautomatic machines.

Here is a picture of DSN201, where it is written that there is overvoltage protection:

All differentials are produced at the same factory in Italy as the UZO wheels.

5. DIN rail switches (SHD200, SD200, OT63F3).

A switch is simply a switch for something. Usually we place them at the entrance to the switchboard, because we already have an input machine (on the stairs or in the shield on the pole). Some people do not understand why it is necessary to install a more expensive switch, and not duplicate the machine. I have a certain logic, which I will explain:

- There MUST be something at the input to my shields that will turn off the entire shield completely. When should you turn off the shield? Well, firstly, in case of an accident. For example, if our emergency voltage protection (UZM-51m) has tripped and it is clearly visible that this will last for a long time (neighbors are running around, screaming, noise). I turned off the shield right from the apartment and went on to sleep. Secondly, in the event of an emergency, there is no time to understand the shield, and it is easier to turn off the entire shield at once. And thirdly, simply for the duration of work or maintenance.

The switch looks different from the machine gun, and I try to place them in the upper left corner of the shield. Therefore, you can immediately see where to run and what to turn off. - There should also be a place in the panel where you need to connect the input cable. Previously, when I made my first simple shields (like a shield), everything was simple and clear: the input zero could be screwed onto the busbar, the phase could be pushed under the machines. Or all this went straight to the UZOshki. But now my boards are complex, and the input zero can go with a 10-square-meter wire to some cross-module and from the same place with a 0.75-square-meter wire to the voltmeter (such a connection can be made if you assemble the shield with a soft PuGV wire and crimp two wires into one). Therefore, the same switch at the input also solves the second problem: the input phases and zero enter into it. Strictly in one place, strictly in the device, which is almost always designated as “Q01” in my shields. And PE goes straight to the bus. And you can't go wrong here.

- If we, then we understand that if we install an introductory circuit breaker in the apartment panel again, then this will not save us, and this circuit breaker will not turn off first - all three of such a chain can still work: both on the stairs and in the panel on input and group to the line. So why do we then produce oil if we have a special thing - a switch-switch that does not work like an automatic machine, but simply turns off the line? In this case, we will have one input machine - in the floor or input panel. And if we want to replace it with a selective one, we can install the S750 DR once.

That's why I put switches at the input to the switchboards. If someone has no money at all and needs to save every thousand rubles (situations are different), then the switch can be replaced with an automatic one without any problems. ABB has two options for switches that we can use in panels. These are switches of the OT series (and even), which can be used at the input or for switching the network<>generator and ordinary switches in the format of a regular machine. We are interested in the latter.

Once upon a time, ABB had a series of modular switches E200 (the last number is the number of poles, as elsewhere in the designation). This series was very bad - its housing broke, and the design inside was crappy. This series has been completely out of production since approximately 2015 (EXCEPT FOR 80...125 A MODELS) AND IS NO LONGER PRODUCED. If you see a mention of this series in the project (in denominations up to 63A inclusive) - I remind you, beat the lazy designers with a pissing broom and tarpaulin boots. Or send them to me for training!

10. ABB Electrical Equipment Handbook.

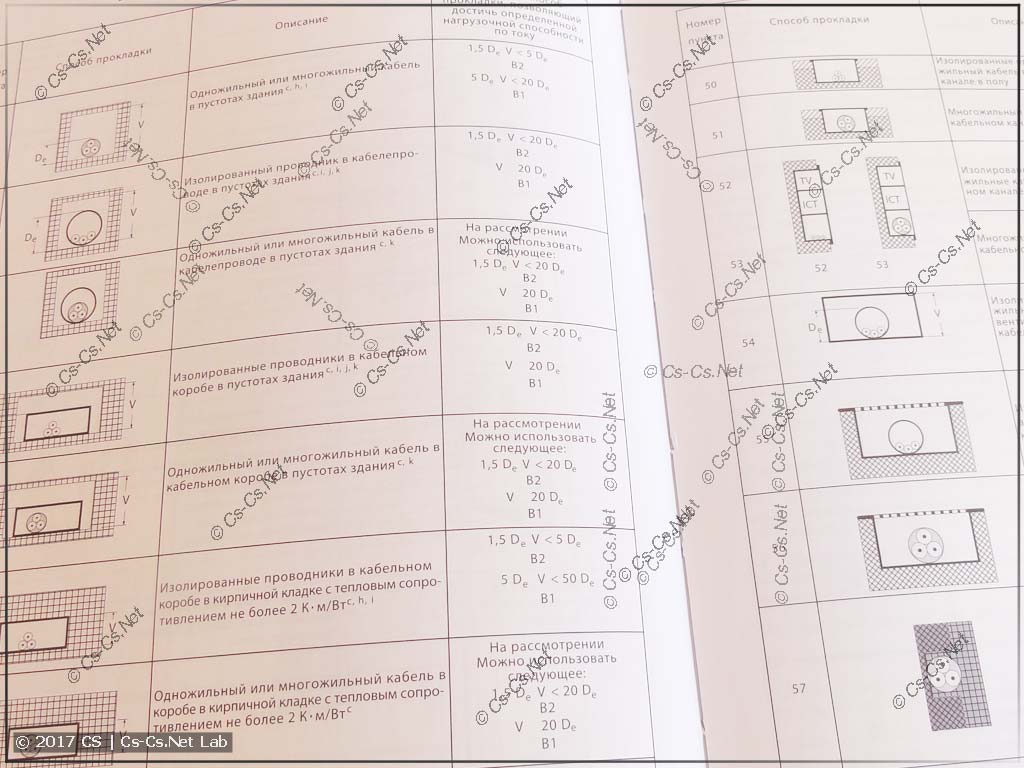

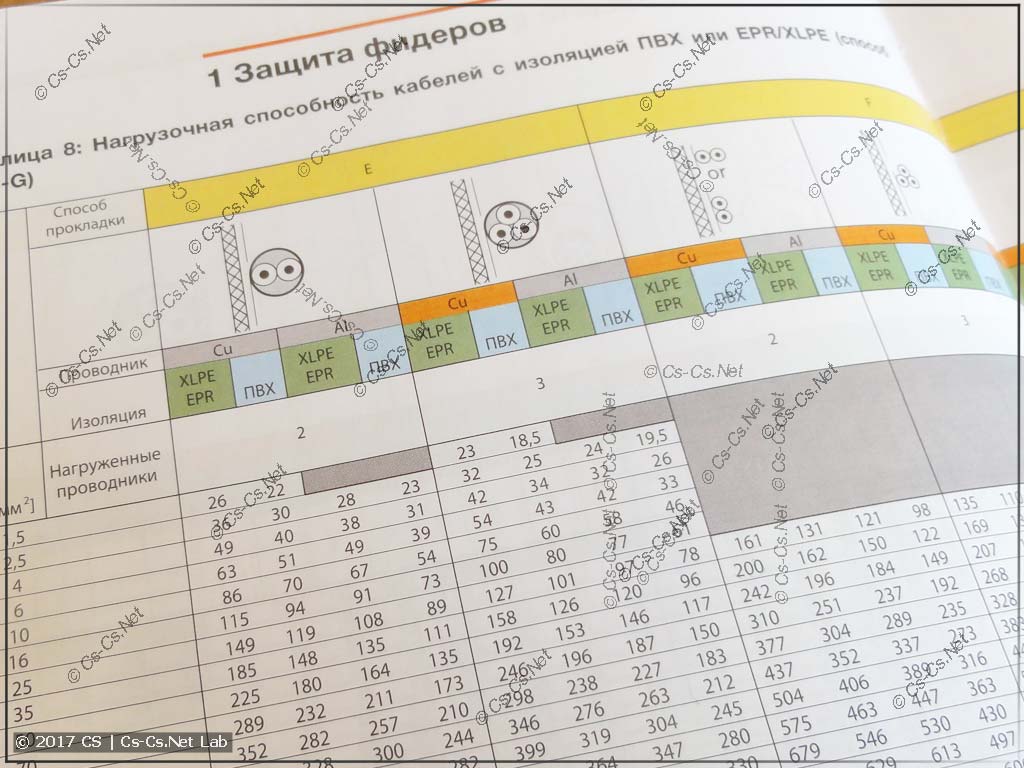

Well, ABB also got confused and made their own directory, in which they collected the latest GOST standards for laying wiring and protecting lines. You can download it here: , I posted it a long time ago.

What pleased me most was how the methods of laying lines and their protection were described there. There are methods that are not described in the PUE. For example, an open layout along the ceiling and lowering to the lamps, which we can see in any restaurants where lamps descend from the ceiling.

First we look at the line laying, and then according to another table permissible currents cables or wires. Fucking convenient, with pictures and without those stupid PUE tables that confuse everyone.

General information and features

The first principle of the system is full functionality. The second is the optimal dimensions of the device. Full functionality means increased security for the user and at the same time more wide possibilities when selecting low-voltage systems that are required for connection and separately for adjusting the load value. "Principle" optimal sizes" means that the use of the internal electrical zone switchboard will be rational due to the fact that a modular structure is used. This significantly reduces the amount of work required to install electrical equipment and at the same time raises the properties of switchboards to a qualitatively new level.

Basic basic functions is protection, management, measurement and control. Especially for them, the system has developed small-sized special devices System pro M.

Any devices intended for protection that are part of a low-voltage system combine switches. There are only two types:

1. VDT - residual current switch.

2. RCBO – automatic differential current switches.

The compactness and versatility of these devices qualitatively changes the entire service process and makes it more easy installation and speeds it up.

Standards and Certification

Requirements applied in the development and manufacture of systems for safety and functional features are the same for everyone and are dictated by international and European regulations. The following standards are met - VDE DIN 40046, IEC 68.2, DIN 50016.

Devices for aggressive environments (tropical version)

Galvanic coating covers the metal parts of the mechanisms, which in turn are made of anti-corrosion steel. This ensures that the System pro M series devices are protected even in the harshest conditions. There will be no oxidation of contacts and metal parts.

Automation from ABB

The company today occupies a leading position in the development industry various technologies for production automation in the field electrical energy and its networks. Thanks to the company's inventions, production efficiency increases and at the same time the negative impact on the environment decreases.

ABB expanded its influence and currently has own production in more than a hundred countries around to the globe, which employ about one hundred and fifty thousand people. In our catalog www.site you can see a large selection low voltage equipment companies ABB.

The main direction of the company is the production of various electrical equipment and electrical installation devices, such as circuit breakers, sockets, dimmers, switches and even. Products for Russian market produced in Russia, and for European in Europe.

Advantages of the electrical manufacturer ABB:

1. Quality due to extensive experience in the electrical energy systems industry.

2. Large assortment and versatility. Only electrical installation products made in six thousand different models.

3. Optimal price, which is typical for automated production and enterprises with a large turnover.

ABB residual current devices are devices that are designed to provide protection to electrical appliances and people from possible electric shocks resulting from short circuits. Thus, they will be able to protect against:

- Fire, which can be caused by an accidental spark from an exposed wire;

- Impact electric shock in case of touching a device that has a leak;

- Uzo ABB will also be able to warn and prevent equipment breakdowns.

Abb RCDs today have a wide range of different mechanisms that differ in characteristics, but they all have the durability and reliability that is inherent in ABB.

ABB circuit breakers

Abb circuit breakers are an essential part of every home's electrical supply. As you know, power surges can ruin all existing equipment that is connected to the power grid, but the machine, under abnormal conditions (for example, a short circuit), turns off the voltage supply. Today, ABB machines in the modern market stand out for their favorable price, incredible reliability and a wide range of products. In the product catalog, each buyer will be able to select the machine he needs, taking into account the rated current, number of phases, and trip class.

Differential automatic machines ABB

Speaking about ABB differential circuit breakers, it is worth noting that they combine the functionality of both automatic machines and RCDs at a very reasonable price. Thus, ABB automatic machines will be able to save your health and property in such emergency situations, How:

- Damage to household electrical equipment due to a power outage;

- Sudden power surges;

- A break in the electrical network in partitions and walls, which can lead to a fire.

ABB automatic machines, with their wide functionality, low price and high reliability, are perfect choice to ensure high-quality protection of the electrical network in your apartment or house.

The AnLan company is one of the leaders in the network equipment market in Russia. Our catalog presents a wide range of equipment and components for creating networks of varying complexity. Sale of network equipment - from cables to cabinets - is the main activity of our store.

The company can confidently guarantee high quality products, because cooperates directly with domestic and foreign manufacturers and is the official supplier of most of them. Cooperation with us implies a number of undeniable advantages for our clients and partners:

- The range of network equipment in the AnLan online store includes hundreds of items and is constantly being updated. Whatever product you need, you can always find it on the pages of our website, be it telecommunication cabinets or optical patch cord.

- Network equipment is sold at affordable prices. But significant discounts are provided for wholesale buyers.

- Prices in the AnLan store are quite competitive, because... the company is a direct dealer of many famous manufacturers network equipment - Cabeus, Legrand, DKC, APC, D-link, Ecoplast, Hyperline, and others.

- The equipment is fully compatible and meets accepted Russian and international quality standards.

- All network equipment comes with a warranty.

Our catalog presents only proven, certified equipment that performs its main functions at the highest level.