Types of shelves for shoes. Shoe shelves - ideas for narrow and wide hallways

How to save and make original stand under your own shoes - find out here!Ideas, useful tips, manufacturing instructions.

- 1 Let's do stylish stand DIY under shoes

- 2 Types and purpose homemade shelves for the hallway

- 3 Materials and tools for making shelves

- 4 How to make a shelf with your own hands

- 5 Wooden shoe rack

- 5.1 What will you need?

- 5.2 Assembly of the structure

- 5.3 Practical shoe rack from chipboard

- 5.4 Beautiful shelf for laminate shoes

- 6 From profile

- 6.1 Step-by-step instructions

- 6.2 Downtime shoe shelf from boxes

- 6.3 Corner stand under shoes

- 6.4 Construction connection

- 6.5 Decorative elements

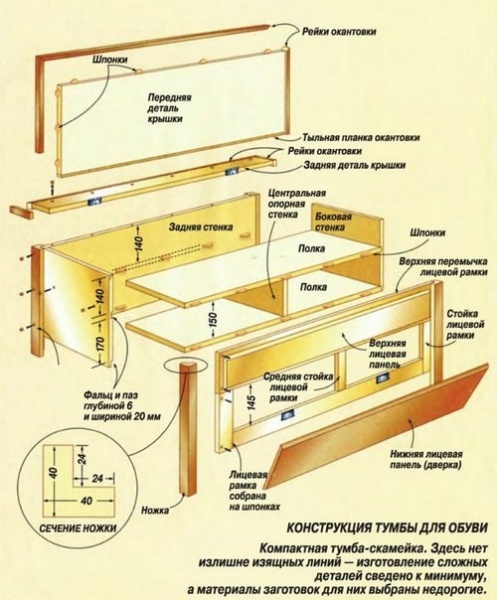

- 6.6 Making a carousel shelf

- 6.7 How to do

- 7 Interesting ideas

- 8 Photo gallery

A beautiful shoe rack can become not only a place to store shoes, but also a full-fledged element of the hallway interior. The choice of options in stores is extensive, but the prices are often overpriced. To make a roomy and compact shelf For shoes that fit perfectly into the look of the corridor, you need to put in a little effort and imagination. Let's consider options for making shoe racks from available materials with your own hands.

Types and purposes of homemade shelves for the hallway

Before installation, be sure to measure the space where you plan to place the shoe rack. For small hallway ideal option there will be a narrow (20-30 cm) and high shelf; in a more spacious room, a closed cabinet with a width of 60-90 cm will look good.

Should the shelf be closed? If you want the hallway to look more aesthetically pleasing, this is a good option. Do not forget to regularly ventilate closed shoe racks, otherwise you will not avoid unpleasant odors. This problem can also be solved by installing a lamp inside for drying and disinfecting shoes.

The advantages of homemade shoe shelves are obvious:

- you can use eco-friendly materials;

- the cost of a homemade shoe rack is several times less than in a store;

- You can make a shelf for a hallway with a non-standard layout.

The design of a shoe rack directly depends on its purpose and the number of residents. Here are some popular and practical options:

|

Shoe shelf design |

Description |

|

Classical |

Shoe shelves of this type are popular due to their simple and convenient installation. It can have a regular rectangular or asymmetrical design. |

|

Hanging |

The shelf is attached to the wall using slats, straps or cables. Conveniently folds when necessary (for example, if you need to carry furniture into a narrow corridor). |

|

Corner |

Fastening is carried out on adjacent walls. Great space saver. |

|

Floor |

The support in this design is on the floor. Suitable for spacious hallways, but can also have compact dimensions if the sections are distributed not in width, but in height. |

|

Closed |

This option looks more aesthetically pleasing. Doors can be made of plywood or frosted glass. |

|

Cassette |

Shoes will be stored vertically here; there are 2 or more cassette-type drawers on the door, which slide out when opened. Good for small corridor(width 20-25 cm). |

There are many options for making shelves. The interior can be decorated with shelves made of metal, in particular aluminum; processed clay shelves, dense oak, and glossy plastic look very beautiful. The material of manufacture can be anything, as can the configuration of the elements. Based on the type of installation, shoe racks can be divided into several types.

Materials and tools for making shelves

The selected material for making a shoe rack determines its service life and ease of use. For example, it’s easier to make a shelf out of a cardboard box, but it won’t last long. But as a temporary option it will work great.  When choosing wood as a material, you should take care of the final treatment of the wood with varnish or paint to ensure an attractive appearance preserved for a long time. There is no universal set of tools, due to the peculiarities of installation and material. But you will probably need the following tools:

When choosing wood as a material, you should take care of the final treatment of the wood with varnish or paint to ensure an attractive appearance preserved for a long time. There is no universal set of tools, due to the peculiarities of installation and material. But you will probably need the following tools:

- electric drill;

- glue;

- simple pencil;

- sandpaper;

- fastening accessories;

- screwdriver;

- wood hacksaw;

You will also need varnish or paint, the color of which is selected to match general interior hallway

How to make a shelf with your own hands

Before starting work, it is worth drawing an approximate layout of the future product, where you also need to indicate the dimensions. After this, they begin marking on the material, where they indicate the location of the fasteners (if any), the required length and width. Here are some useful tips:

- When creating a simple shelf for shoes, you can do without using metal fittings - all elements are fastened with self-tapping screws.

- The doors are easy to install if you use awnings.

- Materials should be treated with varnish or painting before assembly. If you do this after, the layer will be uneven, and the procedure itself will be problematic. The process of assembling a shelf for shoes depends not only on the design, but also on the complexity of processing the material, and the features of working with it.

Wooden shoe rack

First of all, a shoe rack should have small dimensions, but at the same time accommodate a sufficient number of pairs of shoes. This is its integral feature. Materials from which you can build this design, many, but the main one is wood. Unlike chipboard and MDF, it will not unstick or swell when exposed to moisture. To do this, the wood should be varnished or painted.

What will you need?

Basic kit for making: wood, glue, screws, glazing beads, varnish or paint. Tools you will need: saw, screwdriver or screwdriver, hammer, sandpaper, drill. Beads, screws, and drills are selected in accordance with the size of the structure. Self-tapping screws need to be small, but capable of being firmly fixed in the structure. Please remember that wood may crack or split if wrong choice screw size.

Assembly of the structure

A depth of 35 centimeters will be sufficient. This distance is enough to accommodate almost any shoe. This will be the length of the sides of the structure. You need to saw off 6 elements of 35 cm each. You can determine who in the family has the largest shoe size and measure the distance along it, leaving 1 cm in reserve. Then you need to distribute 4 bars on one of the elements and make a cut to the depth of the bars. The bars must be spaced evenly.

Each shelf should be able to accommodate 3 pairs of shoes, so its length must be determined based on the 3 largest pairs of shoes in the family. 4 pieces of this length will go on each shelf. To connect the elements, it is necessary to cut out recesses. These places must be secured with self-tapping screws. For a more aesthetic appearance, you can drill holes and use glazing beads and glue that will hold the shoes without any problems. This operation is similar for each shelf. After this, sand the tops of the side panels with sandpaper.

Any height can be set, but a reasonable limit is no higher than 80 cm. High shoes should fit in one of the compartments of the structure. The distance between the shelves (between the floor and the first shelf) should be 30 cm. All connections are made in the same way.

Practical shoe rack made of chipboard

To make a simple shelf for shoes from chipboard, you need to take two sheets of canvas (the dimensions are determined based on the space in the hallway). Will need fiberboard sheet for the back wall. The assembly algorithm is simple:

- We attach the bottom and the shelves themselves to the two side walls. For the screeds, use a drill (8 mm drill); at the end, use a drill with a diameter of 5 mm.

- The folding element is secured with medium-sized self-tapping screws;

- The upper part is attached to 4*30 self-tapping screws;

- The shelves are mounted inside;

- Fasten back wall products.

- This is a budget and uncomplicated option that can be used in any hallway layout.

Beautiful laminate shoe rack

If after renovating your apartment there is unused laminate, you can use it to make a stylish and compact shelf that will fit seamlessly into any design. For production you will need laminate sheets, the number of which depends on the tier and metal pipes with slots. They can be made using a metal grinder. If desired, the structure can be made to any height; for safety, the edges of the tubes are sealed with plugs.

From profile

From profile

An interesting option are shelves for shoes made of profiles and tempered glass (or wood). For manufacturing you will need the following tools:

- glass cutter;

- jigsaw;

- Bulgarian;

- level;

- electric drill for metal;

- screwdriver

You can use a regular colored profile or a galvanized one; the second option will be more reliable, as it is resistant to moisture.

Step-by-step instruction

- The profile is attached to the wall with one self-tapping screw;

- Using a level, check the horizontalness of the markings;

- Screw in the remaining screws;

- The frame is assembled;

- Already cut shelves are attached to the frame.

- This option will look good in a Hi-Teck design.

Simple shoe rack made from boxes

Simple shoe rack made from boxes

The presented design is able to withstand a lot of weight, despite the fact that cardboard is a fairly flexible material. To make it, it is advisable to use boxes from household appliances. Depending on the height and width, take the required number of boxes. The structure is attached with glue, tape, a stapler or another method. The finished shelf can be decorated as your imagination dictates. There is one drawback - this shelf is only suitable for summer shoes.

Corner shoe stand

Corner shoe stand

The most suitable material for creating corner wooden shelf for shoes - larch. It tolerates dampness well and is easy to use.

First, we decide on the size and design of the shelf, draw a diagram and calculate the required amount of material.

For creating corner shelf necessary following materials and tools:

- two boards up to 2 m long (the ends of the boards can be rounded or cut with a wave);

- shelves cut from the same board (the shelves can be cut into different sizes and shapes);

- jigsaw for cutting;

- plane and sandpaper for leveling;

- corners and screws for connecting parts;

- level to check the accuracy of the design;

- antiseptic;

- varnish or paint.

The boards must be sanded and treated with an antiseptic, varnished or painted. Varnish is chosen if you want to emphasize the naturalness and structure of the wood, paint - if preferred rich colors and when deciding to use special design techniques with color play.

Construction connection

Construction connection

To create a lightweight structure, the two main boards are not attached to each other: they are installed at an angle and connected using shelves. First, the lower shelf is attached, then the upper one, the structure is installed vertically and its evenness and stability are checked. Then the remaining shelves are installed.

The space between the shelves must be sufficient, otherwise there will be a feeling of crampedness and congestion.

Decorative elements

To further decorate the shelf, you can use thin decorative slats cut out yourself. Or purchase a decorative wooden lattice partition, and after sawing it, decorate the shelf by adding carved stops.

Using decoupage or aging techniques in painting will also add a fresh touch to the interior of the hallway. Bright color solutions may be relevant to complement the interior.

Making a carousel shelf

The carousel shelf takes up little space and at the same time can accommodate many pairs of shoes. To make it you will need: fiberboard, metal pins and screws.

How to do

Blanks in the form of circles and quadrangles are cut from fiberboard. Using a compass and a strip, markings are made for the pins.

Discs for stands are fixed with discs smaller diameter, which are located at the required height.

Prepare the bottom, on which quadrangular blanks are installed, attached with a corner. The bottom circle is conventionally divided into 3-4 parts (space for 3-4 pairs of shoes on the “floor”).

Interesting ideas

To make a shoe shelf, you can use your imagination and then the most interesting ideas come to mind. unexpected decisions. Here are a few ideas that will be of interest not only to independent use, but also as a gift for loved ones.

On video: DIY shoe rack from an old closet

Inhabitants small apartments Often faced with the problem of storing shoes. Two or three pairs per season for one person is the required minimum, so even a small family of 3 people needs a design that allows them to compactly place shoes in the hallway.

Shoe storage options

There are several main reasons to make a shoe rack yourself. Undoubtedly, it is easier to purchase ready-made furniture, but often standard sizes not suitable for small rooms. The situation when shoes need storage at the dacha is also more practical to solve on our own from scrap materials, without resorting to additional costs. The third side of the issue is the desire to create an exclusive design, striking in its originality and unconventional approach. Let's consider various options installation of shelves for shoes, depending on the final goals - to save space or budget.

From the point of view of saving money, the material for making the shelf is chosen as accessible as possible: it can be carton boxes or cheap plywood. The design of such shoe shelves depends solely on the owner’s imagination:

- From disassembled boxes, using tape and staples, the classic shape of a shoe rack with vertical racks and crossbars is assembled;

- Several cardboard containers of suitable shape are fixed together into a vertical shelf, and then attached to the wall. Its minimal depth allows the structure to be installed even behind a door.

Note! This shelf model is suitable exclusively for light shoes. To store winter boots, you will have to take care of a more secure place.

The plywood construction allows you to achieve good combination cheapness and originality. To do this, assemble a frame in the form of a box, after which it is equipped inside with shelves with asymmetrical bends, allowing you to place shoes various shapes and sizes.

Adherents classic interior It is better to make traditional shelves for shoes made of wood material or combined with metal elements. They can differ in height, have a variety of configurations, and be additionally equipped with doors. It all depends on the material possibilities, the area where the premises will be located and the design of the premises.

For those who like to impress others or simply push away from the usual forms, they will like non-standard approaches in the form of using PVC pipes or equipping a kind of shoe shoe that simultaneously performs two functions: storing and drying shoes.

Budget offers

Available materials in the form of cardboard, plywood or slats will allow you to build a shelf for shoes without additional expenses.

Cardboard

Most economical solution question - the use of cardboard. Such a product would be appropriate to place in a country house, but in some cases, with a creative approach to design, a shoe rack made of cardboard can be installed in an apartment. One option involves the following steps:

- Markings are made on cardboard boxes with a pencil;

- elements of the workpieces are cut out with a special knife;

- boxes are formed from rectangles;

- the blanks are connected to each other, forming grooves for shoes;

- the elements are connected to each other by brackets;

- the shelf is fixed to the wall.

As mentioned above, it is also possible to build a standard model, where transverse elements are attached between the vertical parts. The connection is made using tape and staples. Decorating it with decorative film will help give a cardboard shoe rack a more aesthetically pleasing appearance.

Plywood

A shelf made of plywood will last much longer. To make it you will need:

- jigsaw and drill;

- perforator and hammer;

- pins and glue.

Having built a frame of the required dimensions, the internal filling with shelves is done at your discretion, depending on the number of shoes stored and their size.

Important ! Before joining, all parts are thoroughly sanded.

A more simplified model is a shelf assembled from U-shaped elements that can be attached directly to the wall or fixed on a previously prepared panel. As in the case of cardboard, it is recommended to cover the final structure with decorative film. This will not only make it attractive, but will also protect it from moisture, making it easier to care for.

Reiki

Slats can be a practical solution for a summer house. Minimum Required tools: screwdriver, hammer and nails. The design of the shelves in this case may be different, but all options have advantages, these are:

- saving costs on purchasing materials;

- ease of manufacture;

- good ventilation.

What models can be built from slats:

- The most primitive one is to connect two slats of different widths. There is a wider part at the bottom and a narrow one at the top. Shoes are inserted into the shelf with the toe.

- The following design of a shelf made of slats resembles the semblance of a pallet placed vertically. Pinned to vertical racks cross bars, the shelf is additionally equipped with slats for fixing to the wall.

- It's also easy to make a traditional shoe rack shape. For convenience, the upper part can be equipped with an ottoman.

It is worth noting that in each case it is better to carefully treat the slats so as not to damage the shoes in the future. At the final stage, it is preferable to carry out finishing work, be it painting or varnishing.

Classic designs

Traditional models of shoe racks are made of wood, chipboard and metal elements. In most cases you will need:

- saw and plane;

- screwdriver and screws;

- metal corners;

- sandpaper;

- wood glue;

- tape measure and pencil;

- finishing material (paint or varnish).

An essential condition is preliminary design. You can use ready-made diagrams or draw a sketch of a shoe rack yourself.

Tree

Let's talk about one of the many options. A suitable material would be a board with a width of 25-35 cm, the thickness of the workpiece is 2 cm. Manufacturing includes the following steps:

- The vertical side walls are being prepared. The height of the parts is 80-90 cm.

- For shelves, 4 fragments 60-70 cm wide are cut out;

- All items are processed sandpaper;

- Using self-tapping screws, the crossbars are connected to the side walls.

- To enhance strength, metal corners are fixed at the rear ends of the shelf.

- The final stage consists of finishing works- after treatment with primer or stain, the shoe rack is painted or varnished.

Chipboard and MDF

A shoe rack made of chipboard with an ottoman combines practicality and attractiveness. In the process of preparing parts according to the selected project, it may be necessary to remove chips and irregularities using a sander. Edges ready-made elements The future shoe shelf is covered with a special tape using a hot iron. Fine-grained sandpaper is useful for sanding corners; this will prevent damage to the shoes during storage. In some cases, slots should be prepared; the parts of the shoe rack are often connected using confirmations. To decorate an ottoman, take care of purchasing foam rubber and leatherette in advance.

By showing your imagination, you can make an original and practical shelf for shoes made of laminated chipboard. Material consumption is determined depending on the number of shelves; you will also need to purchase metal tubes and clamps to hold the transverse elements of the structure. The edges of the metal tubes are closed with plastic plugs.

A corner model of a shoe rack will fit well into the interior of a square hallway. The stages of its production are not much different from previous versions:

- a diagram of the future shelf is being prepared;

- for the material you can choose laminated chipboard or MDF;

- parts are cut out according to the selected dimensions;

- All roughness is removed from the edges, after which they are decorated with tape;

- The structure is assembled using confirmations.

The “Slim” shoe rack model has maximum functionality. Accommodating a large number of pairs of shoes, it has a compact size. It is extremely difficult to do it yourself due to large quantity accessories. Much easier to purchase finished design and get busy self-assembly. The following diagram will help you:

Use of metal elements

The designs have external lightness, in the manufacture of which they used for the transverse shelves metal elements. Working with such a sketch requires the presence of a grinder, a jigsaw for metal and certain experience. Having blacksmithing skills, you can create an exclusive model of a shoe rack with forged elements.

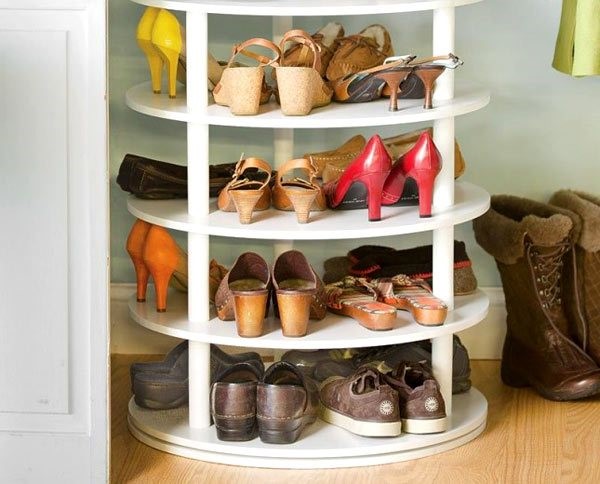

Extraordinary models

Non-standard shelves also have two directions: shape and material used. Sufficient space in the room allows you to install a round shelf for shoes; its ease of use is facilitated by a rotating mechanism. The most difficult stage will be cutting out round blanks and installing a mechanism that ensures the mobility of the device.

Note! The radius of the circle should be larger than the largest shoe size you have in your home.

If we consider non-traditional options for shoe shelves in terms of the chosen material, it could be a stand made of sewer pipes PVC. What does the assembly of such a shelf include:

- Sawing material to length, taking into account shoe size.

- Sanding the edges with sandpaper.

- Decoration of sections with decorative film. In this case, the imitation of birch logs looks very impressive.

- The individual elements of the shelf are connected to each other by plastic holders or belts. If necessary, this design of a shoe rack can easily be supplemented with new cells.

Regardless of which model you like best, important point is the final finishing that can turn the most unpresentable shelf into an exclusive furniture structure.

Almost every person has at least 4 pairs of shoes - winter boots, spring boots, summer shoes, sports sneakers or sneakers that can be worn in the fall. But as a rule, a woman’s shoe wardrobe is much wider - flip-flops, flip-flops, clogs, ballet flats, flip-flops, ankle boots, Ugg boots, felt boots, shoes with high, medium and small, thin, square heels, with a sharp, round and rectangular toe, open and closed heel or toe... It is estimated that the average Russian family of three uses about 10 pairs of shoes per season! All of it must be stored somewhere. You can, of course, without further ado and place everything on the rug near front door. But sooner or later, a bunch of malas will happen on this very rug. And all this looks, to put it mildly, unaesthetic. In this case, shoe shelves will come to the rescue. You can buy them at a furniture store, spending from 3 to 20 thousand rubles, or make them yourself - a product from ordinary cardboard boxes will cost you pennies.

Let us note in advance that if in the hallway you need space not only to store shoes, but also outerwear, then in this case it is better to immediately purchase a wardrobe. By the way, you can buy a sliding wardrobe in the online store Cult of Furniture at a relatively low price, and quite High Quality. Here you can find a wide variety of models, differing in size, shape and cost.

You can make a shoe rack with your own hands from scrap materials that you can get for free, and legally! Of course, the simplest and cheapest shoe racks will not last for decades.

At proper care and “polite” treatment will last for 3-4 years. But this is quite enough - after a while you can make a new shoe rack.

A shoe rack can be made from any available material, even old cardboard. The main thing is to treat the product with varnish. so that the cardboard does not absorb moisture and does not collapse

“Star Hour”: products from cardboard boxes

Do-it-yourself shoe shelves for the hallway are made from cardboard boxes literally in one evening. To get started, prepare the materials:

- from 5 to 20 cardboard shoe boxes. It is important that the side parts are not too narrow - at least 10-15 centimeters. Where can I get them? Look for houses first. Often such packages are thrown onto a balcony or mezzanine (after all, branded shoes are guaranteed for a month). Not home? Ask your friends and neighbors, call relatives and colleagues. You'll probably collect 10 pieces in a couple of hours. Usually the boxes are made of thick cardboard, with holes on the sides so that the shoes inside can “breathe”. Let there be boxes different sizes(you are unlikely to be able to find the same ones, although nothing is impossible);

- instant glue. You will need 2-3 tubes depending on the size of the shelf.

One costs about 100 rubles. Choose "Moment" or "Second".

They cope better than others with their “professional responsibilities”;

- water-based paint in the color you like.

A five-liter bucket costs about 300 rubles.

You can do without coloring the resulting product. But it will look unattractive and sloppy. Choose products from such manufacturers as: “Paint”, “Dessa Decor”, “Parade”, “Lakra”;

- paint brush. Costs about 100 rubles. Do not choose a wide one; the optimal length of the working part is 5 centimeters.

Take the boxes and remove their lids - you won't need these parts, the storage will be open for ease of use. Place 3-4 boxes in the first row, gluing the side (narrow) parts to each other. Leave for an hour. Next, make the 2nd and even the 3rd row as you wish. Fasten the parts of the system together with glue. Leave the shelf to dry for about 2-3 hours. Paint the resulting product. You can paint the shoe rack outside and inside. You can use it after a day, when the paint has dried well. To make this happen faster, place the shelf in a dry, warm place. And then move it to the hallway. Do not place near a stove to avoid spontaneous combustion.

Shoe rack made of shoe boxes can be original decoration interior, if you decorate it correctly, for example, paint it in a bright color

Shoes are placed on the sides of the boxes; if these parts are quite wide, then there will be no problems.

Important: do not use ordinary cardboard boxes from household appliances or food and drinks for such hand-made items in the hallway. Even after paint treatment, such a system will not be durable and reliable. The slightest moisture will render the structure unusable.

PVC pipes will also come in handy!

If you are thinking about how to make shoe racks for your hallway with your own hands, one of the simplest options is to make them from PVC pipes.

Parts of a shoe rack made of PVC pipe are fastened together with instant glue. This design looks original and unusual

For such a shelf for shoes you will need:

- rigid PVC pipes. They can be bought at any hardware store. Diameter - at least 20 centimeters. Length – from 1 meter or more, depending on the number of cells of your design.

1 m costs about 800 rubles.

If you want to save money, then go to the nearest construction site. Today communications are laid with PVC pipes. Often, trimmings remain and are simply thrown away or taken away for disposal. Agree with the builders - they are unlikely to be against you taking some parts. True, with a size of in this case there may be problems;

- instant glue;

- water-based paint (you can do without it - then the shelf will be white or yellow, depending on the color of the pipe itself).

Take the pipe and cut it into equal parts 15-20 centimeters long. Place 5 cells in the first row, fasten them together with glue. Next, glue the cells on top. Any number of rows is at the discretion of the owner.

For more information on how to make a shoe storage system from PVC pipes in the hallway, see below:

DIY shoe shelves in the hallway made of plywood or OSB board

Plywood or OSB board is an ideal material for making a shoe rack. It is wear-resistant and durable. Will not bend under too heavy boots. Can last 5-7 years. It is stable, unlike, for example, cardboard “colleagues”.

A shoe rack made of plywood is stronger than its counterparts made of cardboard and PVC. This one will last 5 years, no less.

For production, purchase:

- two OSB boards or two sheets of plywood with sides one meter by one meter. Choose sheets at least 5 millimeters thick. They should not have unevenness, defects, cracks, sharp unpleasant odor. A square costs approximately 500-600 rubles;

- a saw or cutter that will cut a sheet or slab;

- self-tapping screws;

- hammer;

- paint for OSB boards or plywood.

Choose products from Sopka companies; "Kaiser" "Parade"; "Tixo."

The paint costs from 150 to 300 rubles for 3 liters.

Take 1 sheet or slab and saw or cut it into 5 strips 20 centimeters wide. Now attach each of the strips to another board or plywood end-to-end. They need to be connected using self-tapping screws. If you want shelves for shoes in the hallway to stand on the floor, then attach the bottom strip of plywood to the very edge of the sheet or slab. The shelf for shoes in the hallway will rest on the lower tier. You can also place shoes on it. The structure is painted and left alone for 12-24 hours, and then used for its intended purpose. It is permissible to decorate the product artificial stone. The shelf can be hung on the wall - then a hammer drill and nails 10 to 15 cm long will come in handy.

To learn how to make shoe stands in the hallway with your own hands from plywood or OSB board, watch the video:

Not like everyone else: original storage systems

What are they used to create shoe shelves in the hallway? As an option:

- old kitchen cabinets. They can be painted in bright colors and placed in the hallway;

Shoe rack even from an old one kitchen cabinet it can be done. will come to the rescue necessary fittings and decor – paint, varnish

- To make a shoe rack in the hallway with your own hands, use metal dish drying racks. They are attached to the walls and shoes, boots, and sandals are placed there;

- Ordinary hooks can become a kind of stand for your own shoes. Although they cannot be called stands in the full sense. Hooks can be attached to the wall at a distance of 20-30 centimeters from the floor and ballet shoes, sneakers, sneakers, etc. can be hung on them. Use only metal fastenings, plastic ones will quickly break off;

- The most popular and easiest to make is a shelf for shoes in the hallway made of wood, or rather, a wooden board. The width of the board is usually 15-20 centimeters. You will need about 3 meters of material. Price per meter – 200-300 rubles. Take oak, ash or spruce. Cut 6 strips of 50 cm each from the board. Place two vertically, and secure the rest horizontally between them. The product must be varnished.

Choose products from Alpina, Deluxe, Bosnia. Price - about 500 rubles per liter.

DIY shoe racks made of wood are natural and environmentally friendly.

A shoe rack made of wooden boards is a classic that does not “get old” over the years. To produce such a product, choose oak, ash or spruce - they are considered the most durable

Any idea can be realized - imagination is only welcome. Before you make a shelf for shoes and boots with your own hands in the hallway, look around. Perhaps it can be adapted for this purpose old chest of drawers, a shelf or even... a buffet?!

You will learn about the original shelves from the video:

Finally

Now you know how to make a shoe rack yourself. To do this, you can use available materials. The most popular are wooden shoe racks. Show your imagination and ingenuity, let your shoe rack be the most sophisticated, unusual and non-standard.

Proper care is important for every shoe shelf in the hallway. Do not place wet or dirty shoes on it. Periodically clean the shelf from dust, dirt, sand. Do not move the structure from place to place too often, only if absolutely necessary. From constant such exposure, the product will quickly become unusable.

Shoes need to be stored somewhere, but is it worth spending money on purchasing an expensive shoe rack? If you wish, you can make your own shelf from any available materials - laminate, and even pipes and boxes. This does not require special carpentry skills.

We will briefly tell you... You will find lists of materials and tools, diagrams, drawings and photographs. It's time to take on your entryway!

The choice of materials and tools will vary depending on the design of the future shelf. Therefore, develop single standard problematic. The most technically difficult solution is considered to be the “slim” solution.

The complexity of such cabinets lies in the installation of a large number of different fittings. All other shelves are much simpler, so when compiling a list of necessary things, we will proceed from the most complex schemes. You will need the following tools:

- screwdriver;

- electric drill;

- hacksaw for wood (or metal);

- chisel;

- ruler;

- Sander;

- pencil.

DIY wooden shoe rack

How to make a shoe rack with your own hands

Before you start self-production shelves for shoes, you need to decide on the design of the future product, its dimensions and functionality. You can create shoe shelves from anything - profiles, wood, slats, laminate, metal and even cardboard. The most popular (in terms of design) are rotating, round and angular models.

In some cases you may need to drill and sand (metal, wood). In some places we will make do with simple gluing and cutting (cardboard boxes). And some varieties will seem exotic to you.

For those who have an old unnecessary closet, the process of making a shoe rack can be incredibly simple, just watch the following video:

You can build a modular shelf with your own hands from plywood, and not just a shelf for shoes. This shelf will be attached to the hallway wall and will not take up much space, and the drawings for its manufacture are quite primitive. In addition to sheets of plywood, you will need:

- drill;

- jigsaw;

- hammer;

- perforator;

- glue;

- pins.

Plywood is cut into identical rectangles (for example, 20x30 cm). The parts are carefully polished, after which the assembly process begins. Sheets of plywood form U-shaped structures that are “nested” into each other, forming something like a labyrinth.

You can hang any number of similar blocks in the hallway. Fastening is carried out using wooden pins and holes drilled in plywood.

Plywood shoe rack

Made of wood

The easiest way is to make a shoe rack with your own hands from store-bought items, rather than from “raw” wood. But since you have decided to start this business from scratch, prepare the following materials and tools:

- sandpaper;

- plane;

- metal corners;

- wood glue;

- screwdriver (can be replaced with a screwdriver);

- saw;

- self-tapping screws;

- varnish (or paint);

- pencil and tape measure.

We will use as material wooden board. The width of the workpiece is 25-35 centimeters, the thickness is a couple of centimeters. The manufacturing process looks like this:

- Vertical side walls are cut out (80-90 centimeters each).

- The support bars and crossbars are being prepared.

- Four fragments of 60-70 centimeters are cut out (these are shoe shelves).

- All workpieces are processed with sandpaper.

- The bars are attached to the side walls using self-tapping screws.

- Metal corners are attached to the rear ends of the product.

- Shelves are laid on fixed beams.

- After assembly, the product is varnished (if desired, with paint of any color).

A DIY wooden shoe rack can also become a comfortable ottoman. In the following video you will learn how this is possible:

From chipboard

Making your own shoe racks from chipboard is in many ways similar to the previous options. In addition to a screwdriver, drill and other standard tools, you will need:

- mounting knife;

- hex wrench;

- square;

- edge tape;

- plugs;

- screws;

- confirmations.

The shelf can be made, or it can be made with rounded or straight ends. IN general outline the process looks like this:

- The sidewalls are marked and cut out.

- Using a sanding machine we get rid of chips and unevenness.

- Take a hot iron and cover the edges with special tape.

- Trim off the excess edge tape with a knife.

- We process the corners with fine-grained sandpaper.

- We make cuts (if the plan requires it) and assemble the product.

The following video will tell you how to create a shoe rack with your own hands from chipboard and pipes:

From laminate

You can create a minimalist and stylish shoe rack with your own hands using regular laminate. To do this, you will need laminate sheets (the quantity depends on the level of the shelf) and metal tubes with slots. The slots can be made with a grinder (using metal circles), and plastic plugs can be placed at the ends.

If desired, you can create frame structure up to the ceiling, but then you will have to think about additional fastenings to the wall.

The number of sections is limited only by your imagination and the size of the hallway.

Photo of laminate shoe racks

From slats

Not a bad solution for country house slats can serve. Having stocked up required quantity Using this material and a minimal set of tools (hammer, nails, screwdriver), you can assemble a shoe rack with your own hands from slats with two or three tiers in a short period of time. Let's list the advantages of such a shelf:

- ease;

- budget;

- good ventilation;

- practicality.

Shoe rack made of slats

From profile

You can also assemble a shelf for shoes with your own hands - from a profile, also using tempered glass as materials. From the tools you need:

- Bulgarian;

- glass cutter;

- electric drill (with metal drills);

- jigsaw;

- building level;

- screwdriver

For your purposes, you can use a galvanized profile or a regular multi-colored one. The first will be more moisture resistant, the second will fit better into the chosen interior. A similar structure is mounted on the wall:

- The profile is applied to the wall and secured with one self-tapping screw.

- After this, take a level and check the horizontalness of the markings.

- The remaining screws are screwed in.

- The frame is mounted.

- Previously prepared glass shelves are installed.

Shoe rack in loft style

From boxes

Most a budget option- a shelf for shoes, assembled with your own hands from cardboard or cardboard boxes. It takes up little space and looks beautiful in a small hallway. Work procedure: do-it-yourself shoe rack made of cardboard

- The contours of the blanks are drawn on the box with a pencil.

- The blanks are cut out using a cardboard knife.

- Rectangles are folded into special boxes.

- The blanks are placed on top of each other, forming grooves for shoes.

- Fastening is carried out with staples.

- The shelf is mounted on the hallway wall and covered with decorative film.

Cardboard shoe rack

From pipes

To make this shelf, you can take water pipes plastic pipes- for example, those from which risers are installed in bathrooms. The tools you will need are a hacksaw. The procedure for assembling a shoe rack with your own hands from pipes is as follows:

- We cut PVC pipes into equal segments - these will be the “boxes” of our shelf.

- Sand the edges with sandpaper.

- We cover the sections with decorative film.

- We fasten the sections together with plastic holders on both sides. The diameter of the pipes and the shape of the structure may vary. New cells can be easily integrated into the circuit if desired.

Pipe shoe rack

We do not suggest doing metalwork or going to a blacksmith. Primitive metal shelf for shoes it is quite easy to do it yourself - for this you need to get an old, out-of-use stepladder. Procedure:

- A fragment of a stepladder is cut out, consisting of several “steps”.

- The edges are sanded.

- The fragment is fixed on the hallway wall.

- They cling to the crossbars plastic hooks- shoes will hang on them.

Homemade shoe rack made of metal materials

Corner

For the simplest corner shelf for shoes with your own hands, you will need MDF sheets, a jigsaw, a drill, drills and screws. It is advisable to have a pencil, a building level and a can of acrylic paint. The actions are:

- Two identical rectangles and several triangles are cut out (their number depends on the tiers).

- The rectangles are fastened with self-tapping screws, forming a corner structure.

- The same self-tapping screws are used to mount the corner shelves inside.

- The shelf is covered with acrylic.

- Now we put the shelf in the corner of the hallway and secure it with dowels to be sure.

Round

To make a round shoe rack with your own hands, you will again need a jigsaw and MDF sheets. The shoe rack will have two tiers, so we will need to cut out three “round pieces”, the radius of which will correspond to the largest shoe size your household. Further actions:

- Having coped with round blanks, you need to cut out rectangular ones (4 pieces).

- Grooves are cut in the middle of the rectangular blanks.

- Rectangles are inserted into each other, forming crosses.

- Using a screwdriver, the crosspieces are attached to round workpieces.

- The ends are sanded and covered with film.

Photo round shelf for shoes

Shoes underfoot in the hallway create inconvenience and clutter up the space. Buying a special shelf or even a cabinet is expensive for many people, and why should it, if from scrap materials in the house and garage you can create not only a functional structure, but also emphasize the design of the hallway. For assembly we will use both standard wood materials and non-standard ones - PVC pipes, pallets and even cardboard.

Depending on what kind of shoes you store in the hallway, the diameter of the pipes will depend. Let's start with more simple option, which is suitable for storing demi-season, summer, children's, and house shoes. We use as a basis sewer PVC pipes with a diameter of 110 mm. This is enough to accommodate shoes up to size 42. For larger shoes, we recommend using pipes with a diameter of 160 or 200 mm. Additionally, for shoes, you will need a hacksaw, a tie belt, aerosol can with paint. The work order is as follows:

- 1. Cut off the required length of pipe with a hacksaw. We recommend 30 cm, but you can make the length shorter or longer, it will all depend on the size of your shoes. One such pipe is a cell for one or a pair of shoes. We make as many of these cells as you need to accommodate the entire collection.

- 2. Sand the sharp edges formed after cutting with sandpaper

- 3. To make the shelf fit better with the interior, paint it in the chosen color. It is more convenient to work with spray paint, but you can use other materials

- 4. We arrange the pipes in a pyramid and tighten them with a belt.

- 5. Insert shoes into each cell and enjoy the result.

It is better to fasten pipes for such a shelf with liquid nails

But if you need a larger shelf for shoes in the hallway, we purchase PVC sewer pipes with a diameter of 300 mm. It will certainly fit not only shoes and sneakers, but also long boots. We divide the selected pipe into equal sections using a hacksaw and also clean the sharp edges with sandpaper. To decorate the compartments, we suggest using paper wallpaper or self-adhesive vinyl film. Decorate not only the outside, but also inner part so that the shelf has a complete look. Insulating or fabric tape of a suitable size will help hide the joints formed at the edges. Next, we fasten the blanks together using hot glue or bolt fastening. You adjust the number of sections in each row yourself. They can be the same, presented in the form of a pyramid or a honeycomb, your imagination is at work here.

Classic wooden shelving unit

A shelf for storing shoes made of wood is a simple and convenient option. Due to the fact that wood lends itself well to processing, it is easy to work with. To achieve the desired shape and size, you will need a plane, sander, saw, hammer, screwdriver set, as well as a pencil and tape measure for marking. To create shelves, we prepare in advance: wooden blocks and strips, screws, varnish for opening.

We saw off six equal bars 33 cm long. These will be the sides of the structure, 2 for each shelf. Their length is the depth of the rack, which is enough to comfortably store an adult pair of shoes. Using a plane, we make cuts on the sides of the sidewalls that correspond to the depth of the long bars on which the shoes will stand. For each shelf, we suggest providing 4 cross beams about 62 cm long, so that several pairs of shoes can comfortably fit on one tier. We insert the long beams into the recesses made in the sidewalls and fasten them together with self-tapping screws. We carry out the same procedure with the remaining shelves, you choose their number yourself. Sand sharp edges with sandpaper.

The optimal distance between each shelf should be at least 25 cm so that you have the opportunity to place not only short boots, but also long boots. In our case, the total height of the structure will be slightly more than 80 cm and consist of three shelves. To connect the shelves we use wooden planks, we also make cuts in them to the depth of the timber every 25 cm.

In our case, we make the lower cuts at a distance of 25 cm from each other, and the last one at 33 cm. Thus, after connecting the shelves, the upper part of the structure will protrude literally 7 cm, this is enough. We cover the upper side strips with a cross bar, making a side. We grind the sharp edges with a machine or sandpaper, and open the structure with several layers of varnish. The shoe shelf is ready. With your own hands, you can fit at least three pairs of shoes on one shelf.

In order to make this unusual shelf, you will need plywood and shoe brushes, maybe old Soviet ones. First, let's decide on the dimensions of the upper part. We measure the dimensions of the future shelf. The length of the structure will depend on the number of brushes. Make the depth of the shelf 5 cm greater than the width of the brush. We have decided on the dimensions, now we cut out two absolutely identical blanks and connect them together with a “book”, we get an angle of 90°. To connect the parts, we retreat 1 cm from the edge of the bottom of the shelf and connect both ends with a screw. We do the same with the second side. Next, we cut out two identical squares from plywood, the sides of which correspond to the width of the shelf, and fix them on both sides, closing the corner.

Let's do the brushes. If they have handles, cut them off with a hacksaw and smooth out the rough edges with a file. We drill two holes in each brush on each side, using screws we screw them to the bottom of the shelf in one or several rows - it all depends on the quantity. The first part of the structure is ready, set it aside.

If the brushes have handles, they need to be sawed off

Let's take another sheet of plywood. It should be equal to the length of the first part, and its width should correspond to the large size shoes On average you will get 35–40 cm, which corresponds to size 43–44. To make the bottom side, we cut out another plywood board equal to total length and 15 cm wide. We fix both parts at 90°, connecting the ends according to the same principle as in the first part of the structure. We get a side for shoes.

Now we connect the first and second blanks together with screws, paying special attention to the corners. We paint it, and when the paint dries, we make two side holes in the back panel for wall mounting. This shoe rack will fit into any hallway and will not take up much space. Thanks to the brush holders, the shoes will not fall over.

This shoe rack is more complicated. To make it yourself, you will need certain carpentry skills, additional tools and materials that may not be available in the arsenal. Let's look at two options for a round rotating shelf with shelves - regular and with a soft pouf for sitting.

Using a jigsaw, we create circles from wooden slabs and mark out the sections

For the first option, we prepare a wooden slab 12 mm thick and cut it into three equal squares of 70 cm each. These will be the bases for the shelves. If you want to make the shelf taller, cut out more blanks. Square shape turn the cut slab into a circle with a radius of 35 cm using electric jigsaw. We cut the slab into equal planks - these are the walls of the sector, in each of which there will be a pair of shoes. Moreover, they should not be the same in height in each tier. For example, for the lower shelf they can be made higher, sections for high boots, and the upper ones can be made symmetrical for shoes and sneakers. To make the sectors even, use a protractor to mark the angles of 60°, and use a ruler to make markings on both sides of the circle. We nail nails onto each line of the sector until we bring them all the way. We apply liquid nails to the markings and fasten the board, finally fixing it with reverse side iron nails. We do the same with the rest of the shelves.

Let's do wooden frame To raise the shelf above ground level, connect it to the bottom shelf. Next, paint all the elements in your favorite color, after sanding the edges. We recommend using white paint and a black border for contrast. So that each shelf rotates freely, we install it between the tiers turntables, fix them strictly in the center, having previously drilled a hole for the bolt and nut.

The final stage will be painting the shelf

The second option is a rotating shoe rack with soft seat. General principle its build is unchanged. However, instead of three or more tiers, we recommend making two, adjusting the comfortable seating height. Also, instead of a frame base, you can attach wheels to make the shelf mobile. Upper part We make the shelves soft. We use batting as a base. We cut out two circles from the filler corresponding to the diameter of the shelf, and two more smaller ones, about 7–10 cm. When laying the batting, we get a protrusion. It's time for upholstery. We cut the fabric along the diameter of the circle with a margin of at least 5 cm. We fix it around the entire perimeter using construction stapler. You will learn more about at what distance to fasten the staples and how to select upholstery material in the article about. We cut off the excess fabric, and to hide the staples, we frame the outline with upholstery tape.

Cardboard shoe shelves, like other cardboard furniture, are gaining more and more popularity in interior design. The base used is ordinary cardboard boxes, which are found in almost everyone’s home. If you don’t have them, think about the nearest store or warehouse, where such boxes lie in a crowd unused. Besides corrugated cardboard To work you will need colored wide tape, scissors, a ruler and a glue gun; if you don’t have one, you can use regular PVA.

Cardboard rectangles are folded into triangles

We prepare the cardboard by cutting out a rectangle with sides 45x35 cm. This size will be optimal for both small and big couple shoes We measure 15 cm from each edge with a ruler and make folds. We cover the sides that we will bend into a triangle with colored tape; this will be the central part of the stand. We fold the cardboard into a triangle along the folds and secure it along the edges and center with colored tape. We repeat the same manipulations with all other sections - we choose their number at your discretion. After you have completed all the sections according to plan, we begin assembling the cardboard shelf. We fasten the bottom row of triangles together with colored tape, and for reliability we go over the joints with a glue gun. We do the same with the remaining rows, fastening them together. When finished, you will have a shoe stand made from triangles. We store shoes in through sections.

Attention, in order for the design to serve you for a long time, shoes must always be dry and clean.

Another budget invention made from cardboard is vertical shelves for shoes. It’s easy to make such a design with your own hands. It is ideal for storing slippers, shoes, sneakers and summer shoes in the hallway and does not take up much space. For work you will need a sheet of cardboard 70x60 cm.

We retreat 2.5 cm along the length of the cardboard from the edges. From these points we measure a vertical line of 25 cm and draw a horizontal segment 20 cm long. We connect the sides, we get a rectangle of 25x20 cm. A square of 25x25 cm is formed between the two rectangles. we retreat the upper corners of the square by 11 cm. We draw diagonals in bottom corners square and we get two triangles on both sides. Draw a rectangle with sides 35x25 cm from the square down. As a result, you should get a T-shaped blank, where the protrusions are two equal rectangles with sides 25x20 cm, and the central part is a square 25x20 cm and a rectangle 35x25 see. Cut off all excess.

To work you will need a large sheet of cardboard.

Now we bend the cardboard along the lines, first vertical in the center, and then diagonal. To avoid damaging the material, use a ruler to make an even bend. After this, lift the bottom rectangle (35x25 cm), then the T-shaped top and wrap the diagonal bends behind the base on both sides. In your toga you should have a pocket with triangular ribs on the sides. Fixing the bends on the back side of the base regular glue for cardboard. For reliability, we recommend a glue gun. We make several such pocket shelves, and then connect them together by the upper protrusion with the same glue. You adjust the number of sections yourself. If desired, the shelves can be decorated, painted and upholstered with twine, and covered with self-adhesive film. At the end, we make a hole in the last section and hang a vertical shelf on the wall.

Simple shelves made from boxes and pallets

You can make a shelf for shoes from boxes that can also be found on the farm. To construct them, you will not need to additionally purchase complex parts and tools. If you are the owner of mesh boxes, we fasten them together in a vertical position using a clamp or strong wire. The front part of the shelf remains open, we put shoes. We choose the number of tiers ourselves, it all depends on the size and depth of the boxes.

You can do the same with wooden boxes. To fasten them together you will need nails and a hammer. This design will look better if it is sanded and the wood is painted. If desired wooden boxes You can not fasten them together, but hang them on the wall in a chaotic manner.

However, the simplest shoe stand is constructed from a pallet. All you need to do with it is sand it and repaint it the color you want. Having placed the pallet in a vertical position, we insert shoes into the spaces between the slats. It will hold up well and will not fall.